System and method for heating feedwater using a solar heating system

a solar heating system and feedwater technology, applied in the field of solar heating systems to heat feedwater, can solve the problems of increasing the cost of solar technology to the site of turbomachine, reducing the output of the power plant, etc., and achieve the effect of increasing the overall efficiency of the power plant and reducing the amount of work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

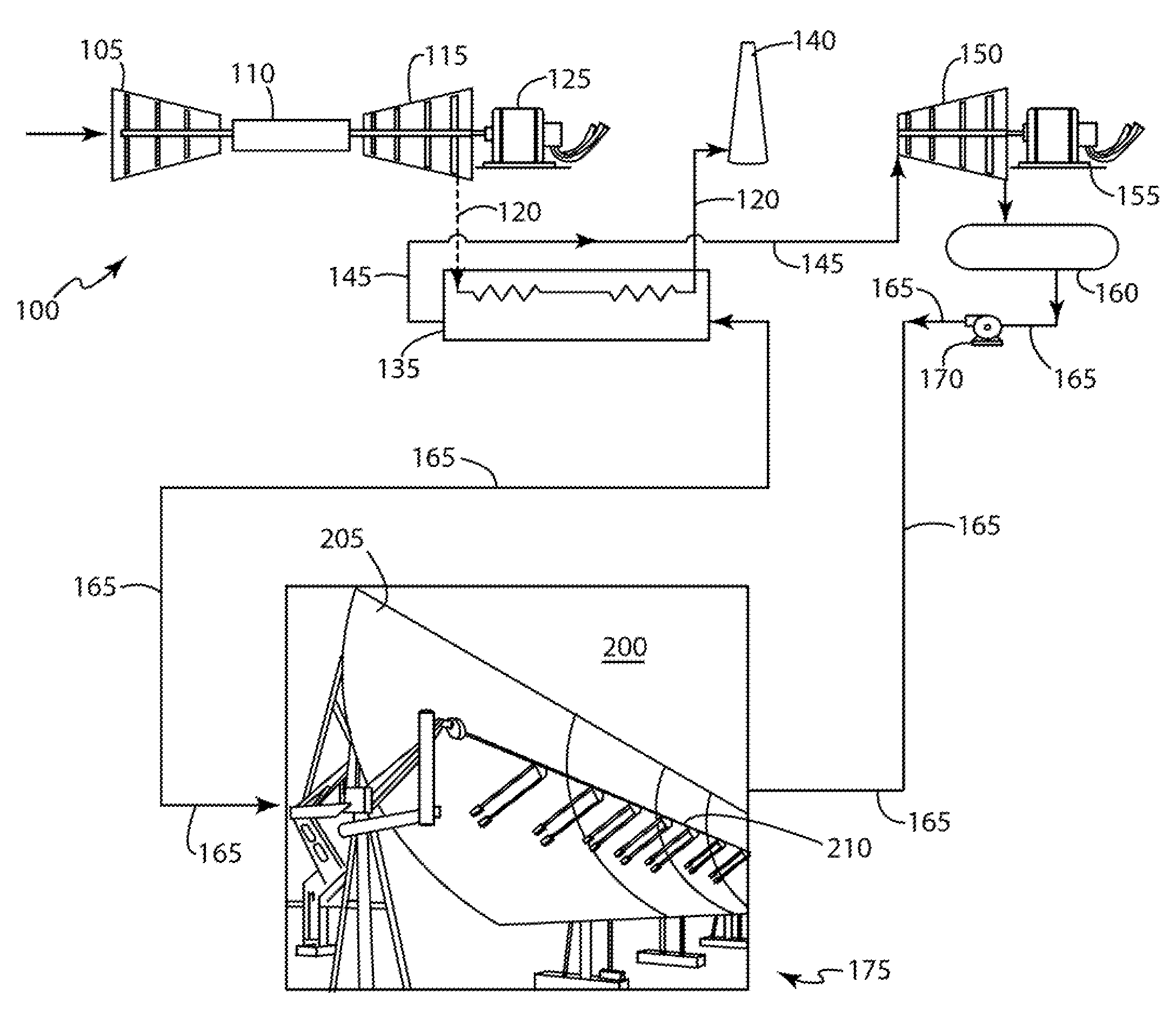

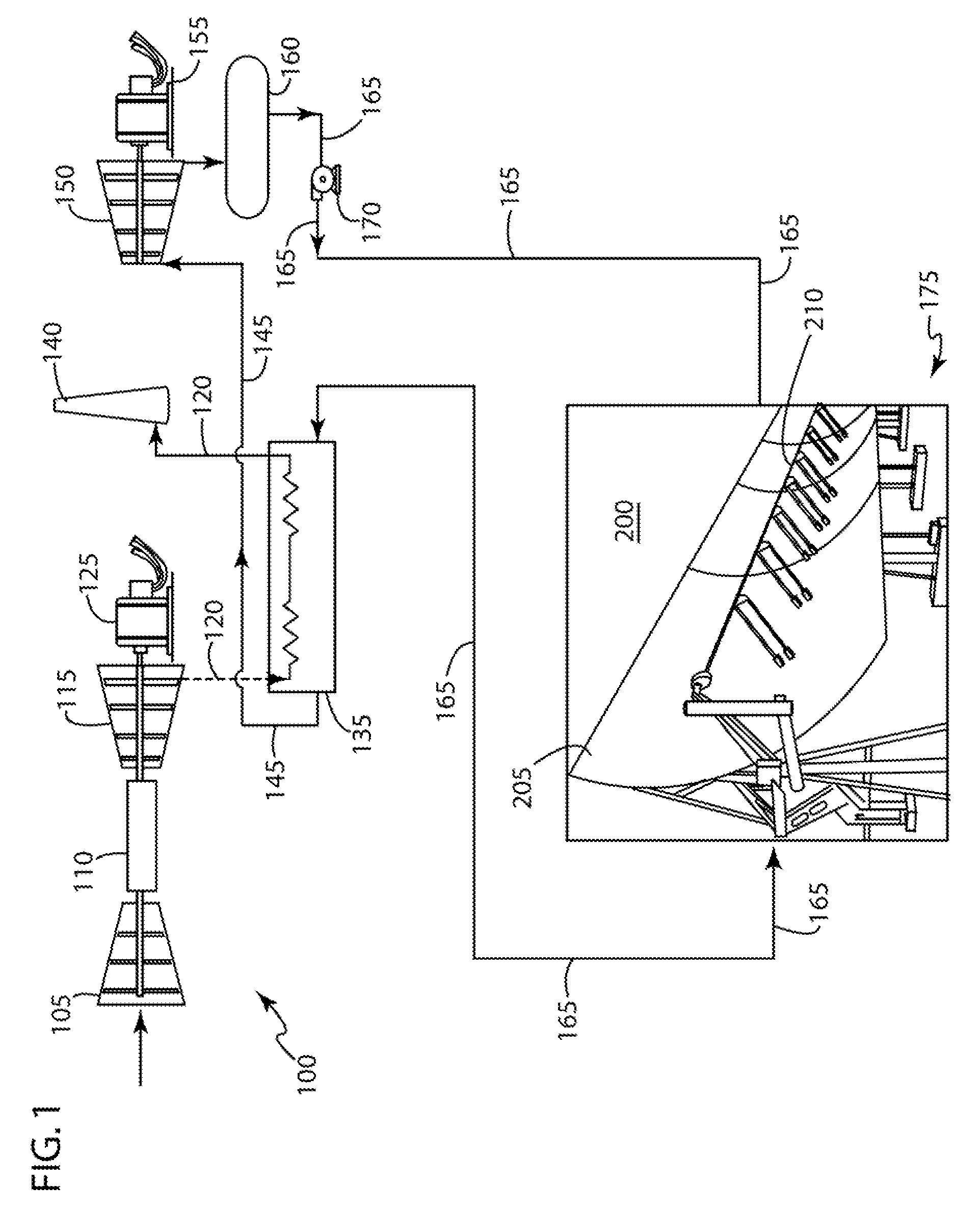

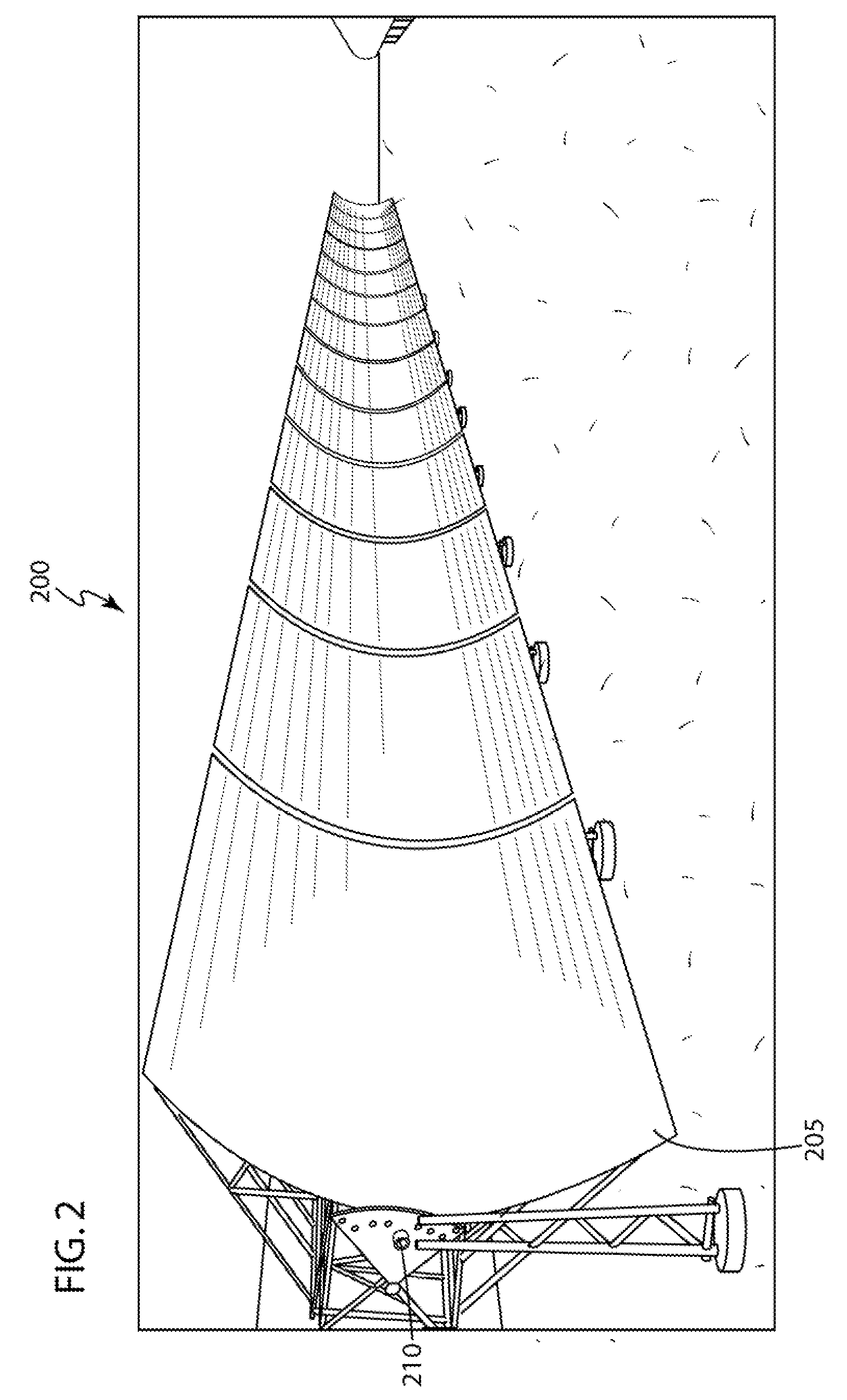

[0024]the a solar heating system 175 may comprise a parabolic trough system 200, as illustrated in FIGS. 1 and 2. An embodiment of the parabolic trough system 200 may comprise a plurality of linear parabolic reflectors 205 that concentrate the sunlight onto a receiver 210 positioned along a focal line of the parabolic reflectors 205. The linear parabolic reflectors 205 are designed to follow the sunlight during the daylight hours by tracking along at least one axis (not illustrated in the FIGS.). The receiver 210 may comprise a pipe through which the feedwater 165 may flow. Here, the solar heating system 175 may heat the feedwater 165 via a convection form of heat transfer, such as, but not limiting of, forced convection, natural convection, or the like.

second embodiment

[0025]the solar heating system 175 may comprise a solar tower system 300, as illustrated in FIG. 3. An embodiment of the solar tower system 300 may incorporate a plurality of tracking reflectors 305 for concentrating sunlight light onto a central receiver 310 near the top of a tower 315. The receiver 310 may comprise a pipe through which the feedwater 165 may flow. Here, the solar heating system 175 may heat the feedwater 165 via a convection form of heat transfer, such as, but not limiting of, forced convection, natural convection, or the like.

[0026]In use, the at least one solar heating system 175 may heat the feedwater 165 from a first temperature to a second temperature. Here, the first temperature may be considered the temperature of the feedwater 165 existing the condensor 160. In an embodiment of the present invention, the first temperature may be up to about 150 degrees Fahrenheit. Furthermore, the second temperature may be considered the heated temperature of the feedwater ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com