Circuit substrate and manufacturing method thereof

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

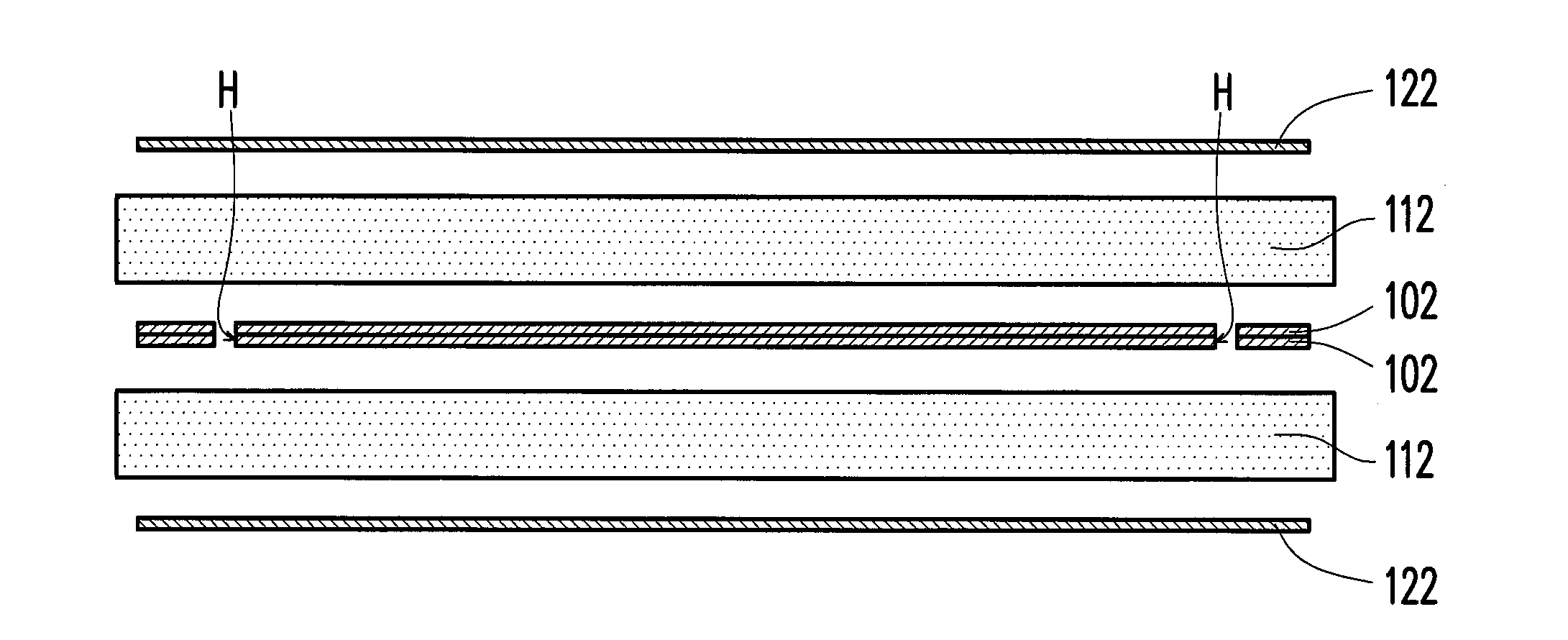

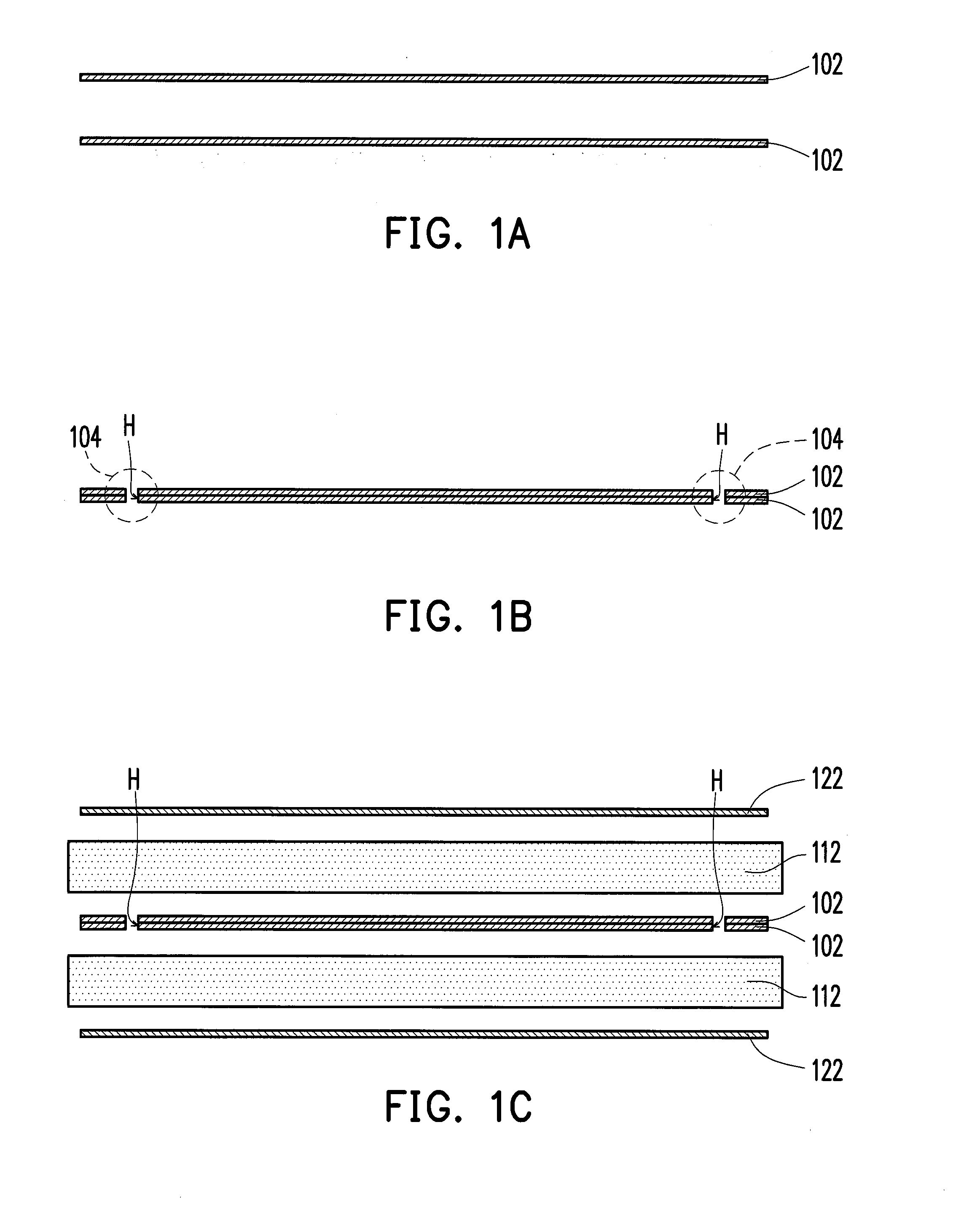

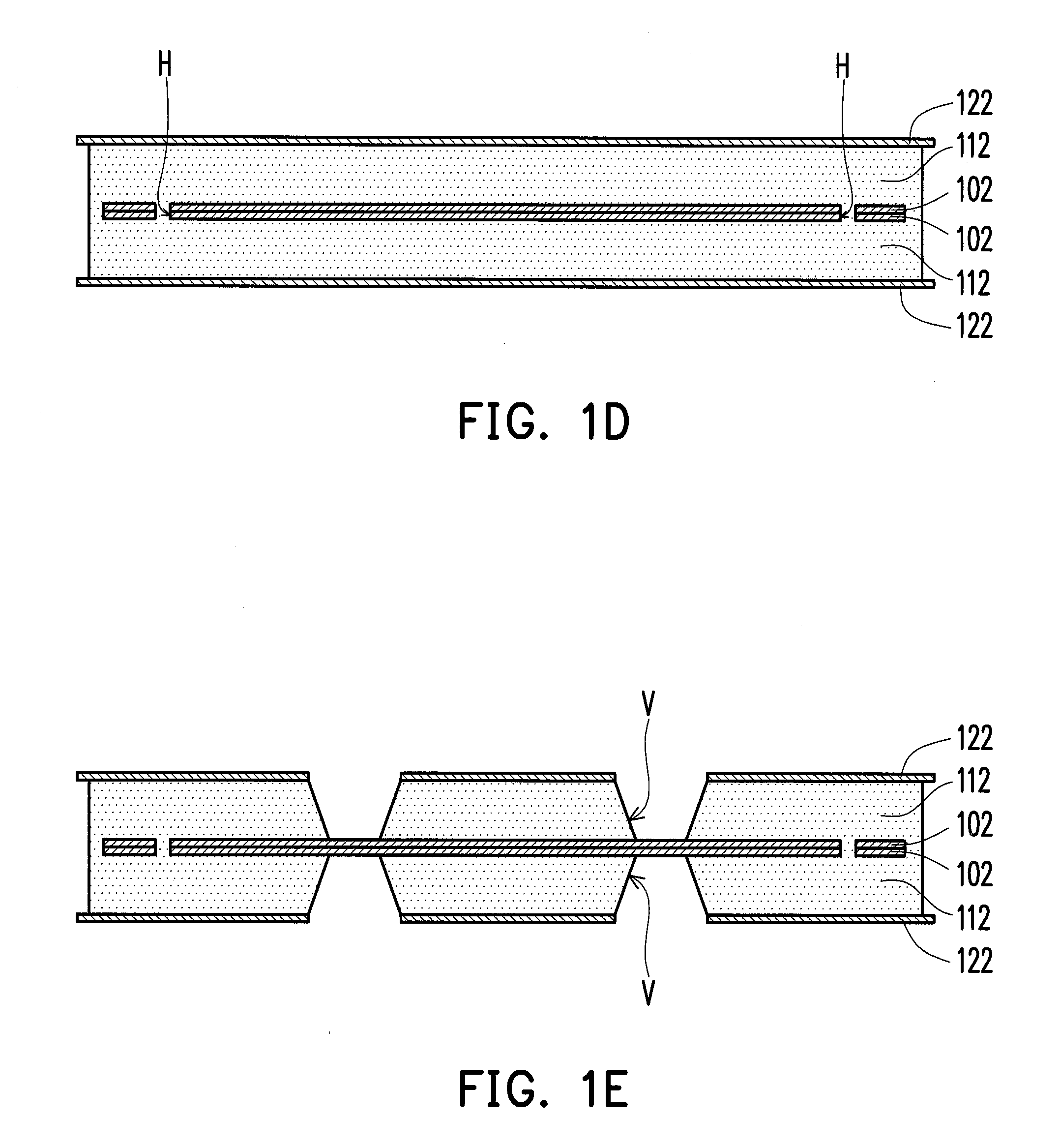

[0035]FIG. 1A to FIG. 1H are cross-sectional views illustrating a manufacturing method of a circuit substrate according to an embodiment of the invention. Referring to FIG. 1A and FIG. 1B, the manufacturing method of the circuit substrate can be described as follow. First, two metal layers 102 are provided, where the two metal layers 102 are, for example, copper foils or other metal foils, and peripheries of the two metal layers 102 are bonded to form a sealed area 104. In the present embodiment, a method of bonding the peripheries of the two metal layers 102 includes welding or spot welding, so that the two metal layers 102 are temporarily bonded to avoid reagents used in follow-up processes from infiltrating there between. Certainly, besides the welding or spot welding, an adhesive can also be used to temporarily bond the peripheries of the two metal layers 102, where a material of the adhesive includes cyanoacrylate ester or polypropylene resin, or other adhesives. It should be n...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Electrical conductor | aaaaa | aaaaa |

| Area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com