Shoe midsole

a technology for midsoles and shoes, applied in the field of structure of midsoles for shoes, can solve the problems of reducing affecting the performance of the midsole, and the layer is particularly susceptible to damage from the elements, so as to reduce the efficiency and lifespan of the midsole, prevent excess deformation of the layer, and prevent excess deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

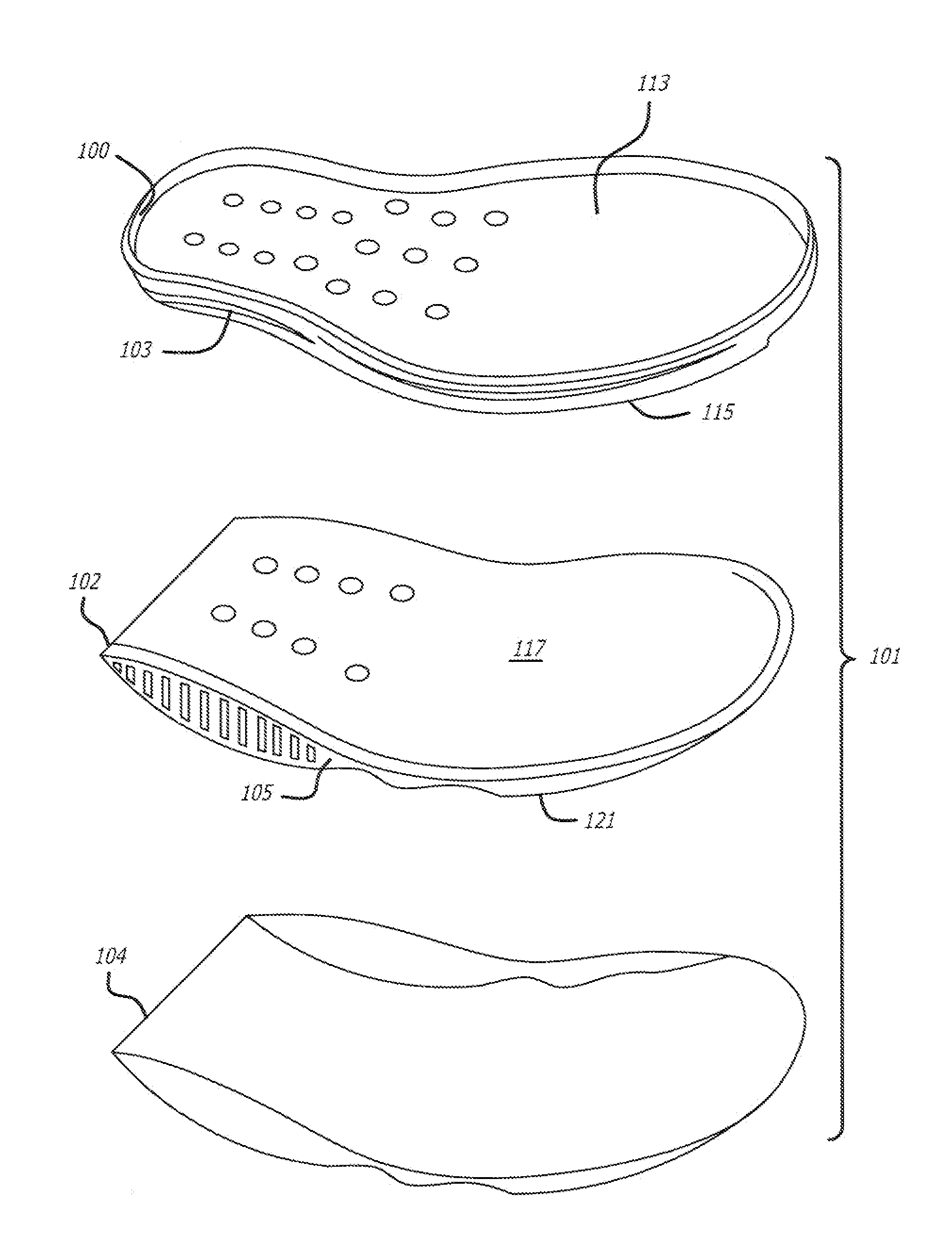

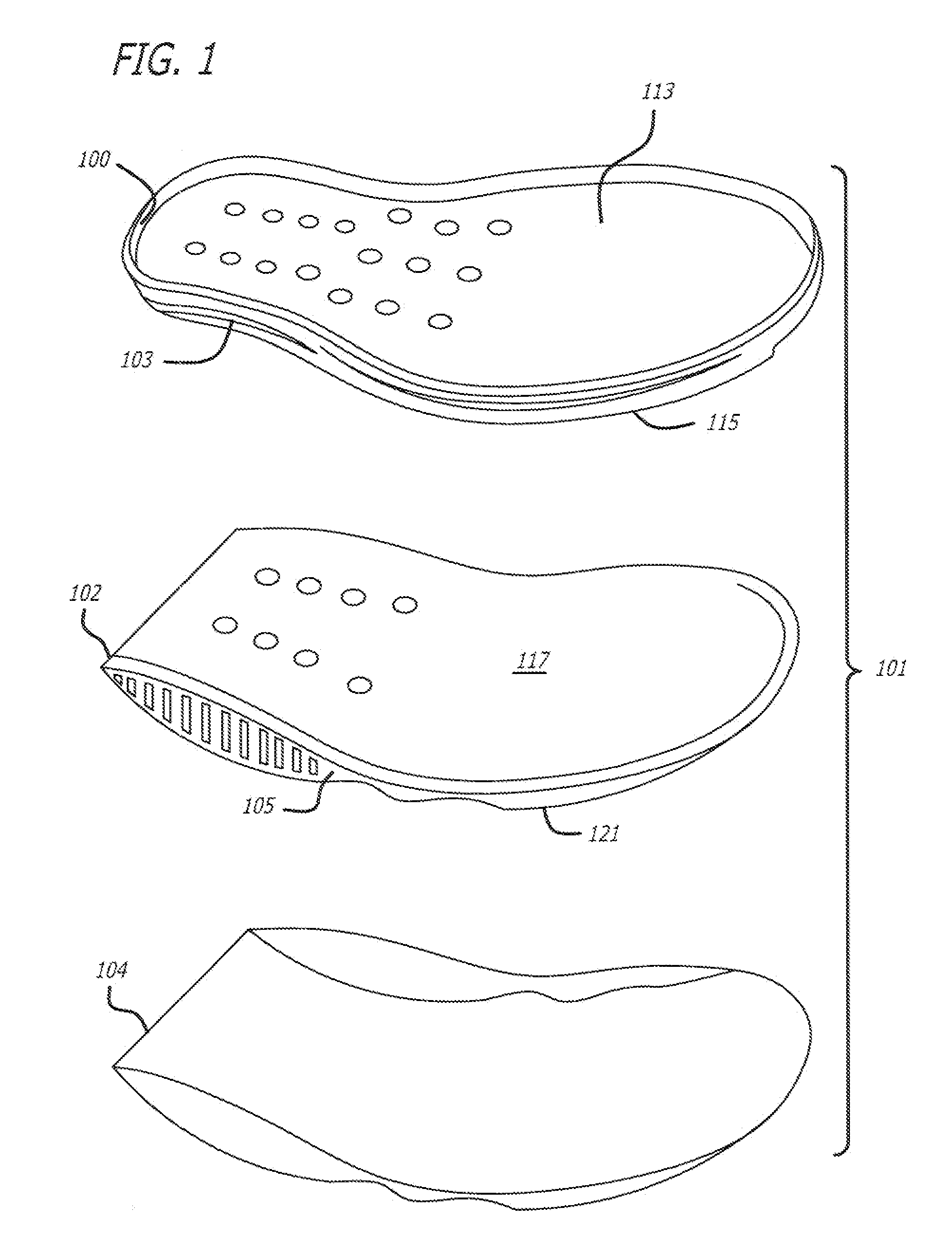

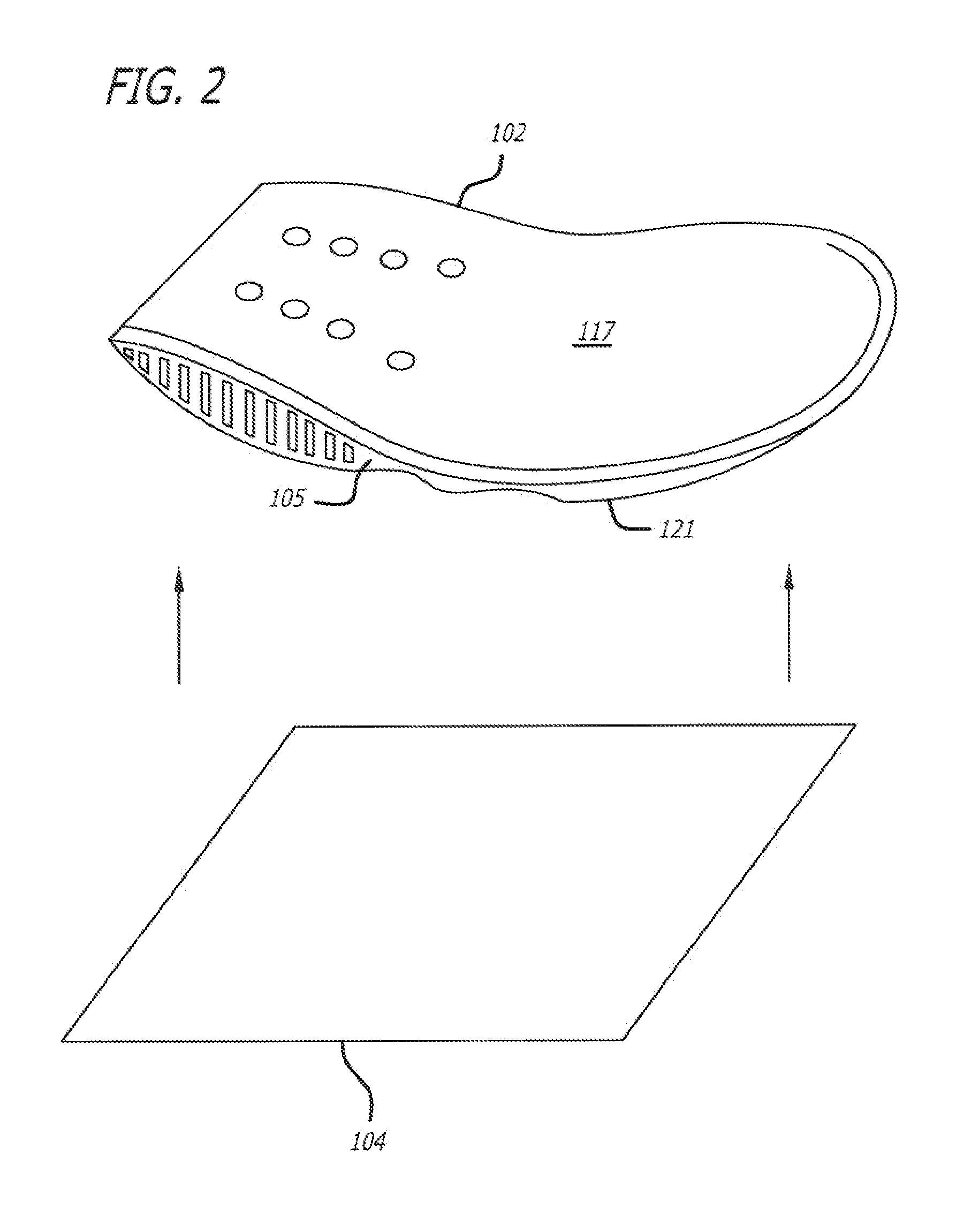

[0026]The invention will now be described with reference to the preferred embodiment shown in FIG. 1. This embodiment shows a midsole 101, the upper layer of the midsole 100, the lower layer of the midsole 102 and the film 104. As used herein, “above” and “below” refer to relative locations of identified elements when a shoe and thus the midsole is in its normal, upright position as shown in FIGS. 1 and 5.

[0027]The midsole 101, as shown in FIG. 1, comprises an upper layer 100 and a lower layer 102. The upper layer 100 may comprise a plurality of sub-layers. The upper layer 100 has a top surface 113 substantially opposite a bottom surface 115. The upper layer 100 has a peripheral wall 103. The lower layer 102 has a top surface 117 substantially opposite a bottom surface 121. The lower layer 102 has a peripheral wall 105. As shown in FIGS. 1 and 5, when the midsole is in its normal, upright position, the lower layer 102 is below the upper layer 100.

[0028]In the preferred embodiment, t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Transparency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com