Press fitting method for heat pipe and heat sink

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

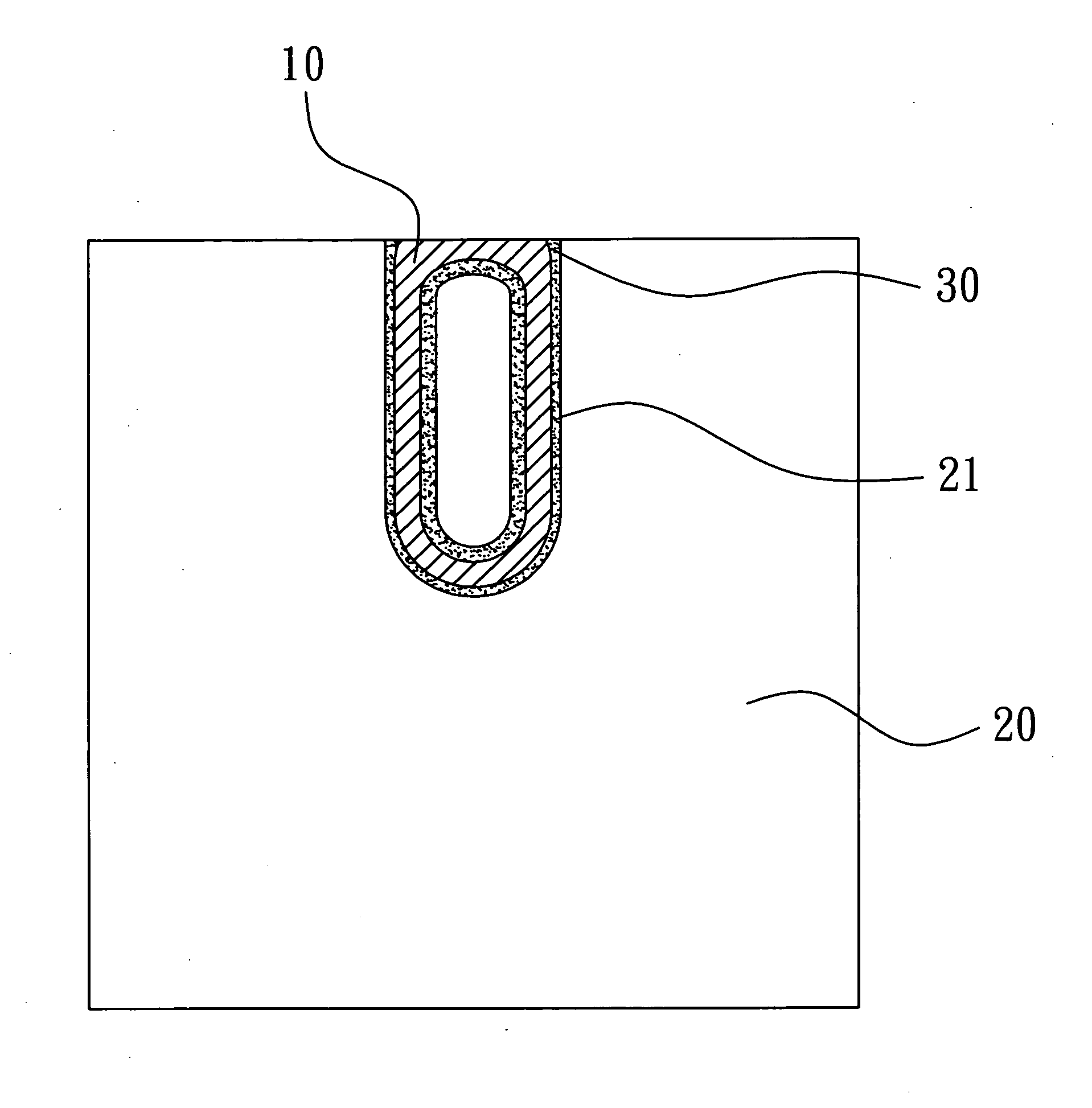

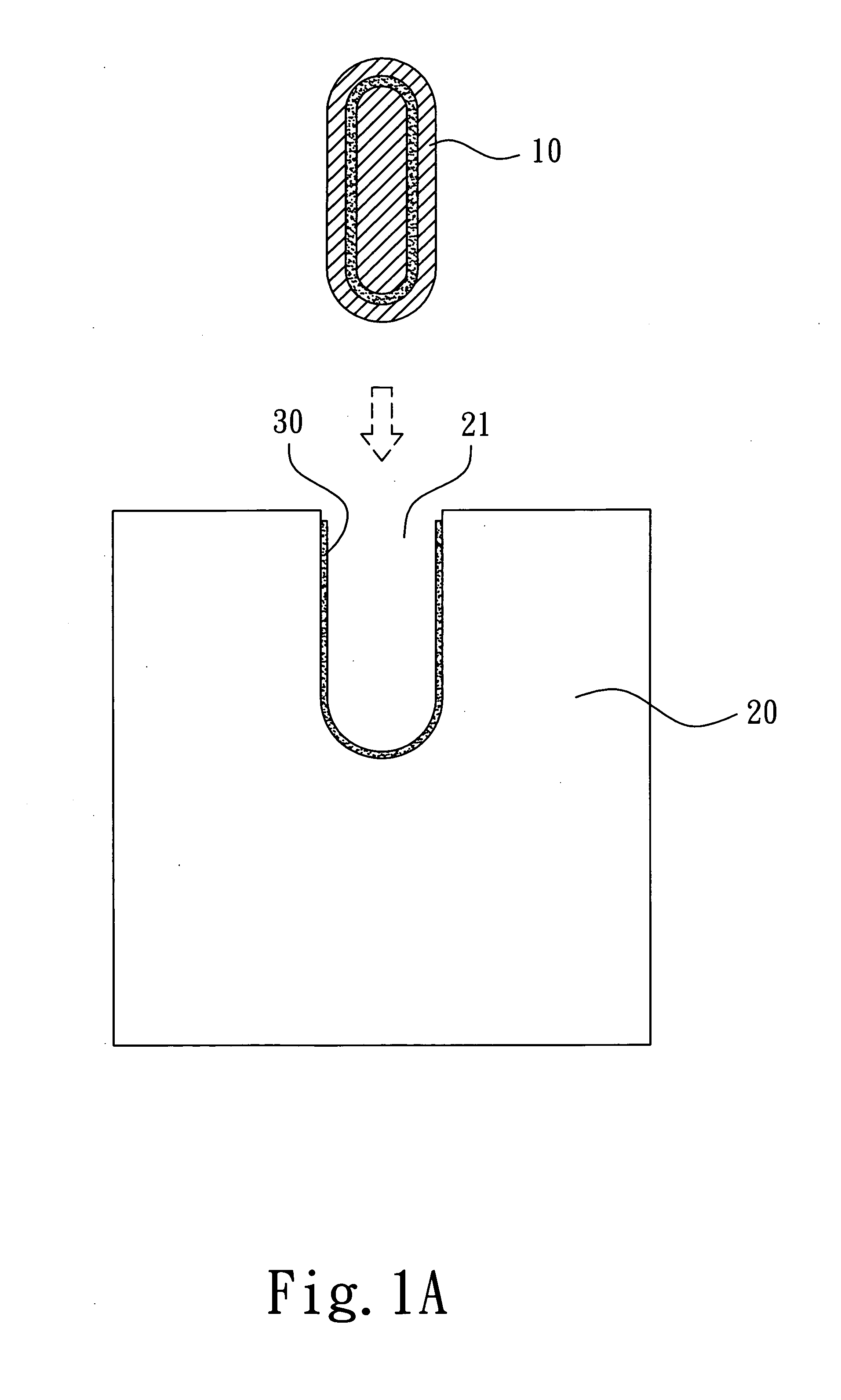

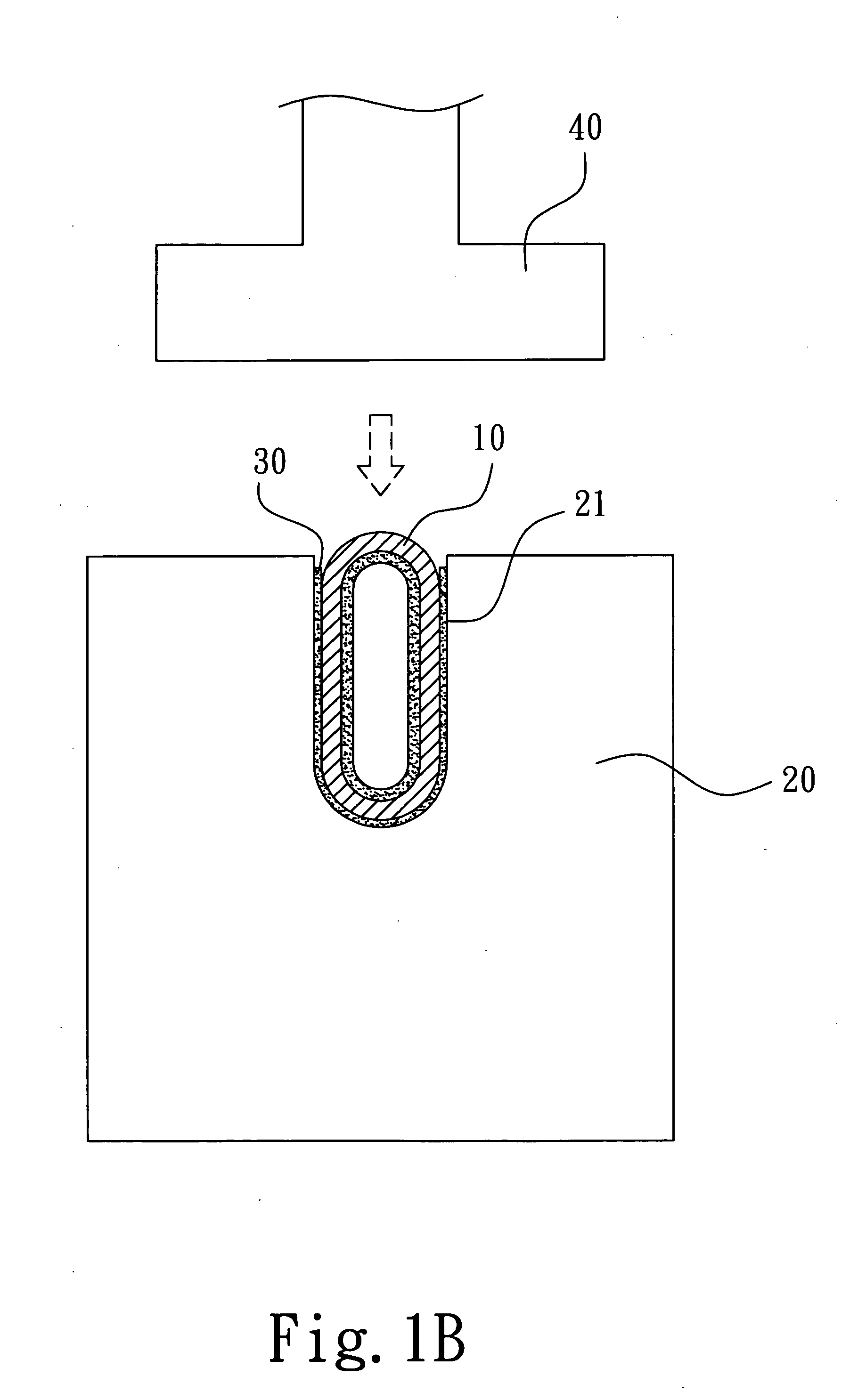

[0012]Referring to FIG. 1A to 1D, a press fitting method for heat pipe and heat sink according to the present invention is illustrated. The embodiment includes the following steps.

[0013]a) At least a heat pipe 10 and a heat sink 20 conducting heat to the heat pipe 10 are provided. The heat pipe 10 is approximately oval-shaped. The heat sink 20 is one of a plate, base, or fin module capable of conducting heat. The heat sink 20 has a groove 21 for receiving the heat pipe 10 on a side thereof. The heat pipe 10 will be protruded from a surface of the heat sink 20 while being received by the groove 21.

[0014]b) The heat pipe 10 is placed into the groove 21. A conductivity medium 30 is smeared around the junction of the heat pipe 10 and the heat sink 20.

[0015]c) The end of the heat pipe 10 protruded from the groove 21 is pressed by a press mold 40 so as to be deformed and fit to the groove 21 as one. (shown in FIG. 1D)

[0016]Through the above steps, the heat pipe 10 is tightly fitting to th...

second embodiment

[0018]The difference between the two embodiments is that a heat pipe 10a of the second embodiment is below (or level with) the surface of the heat sink 20 while being received by the groove 21 of the heat sink 20. The heat pipe 10a is placed into the groove 21. The conductivity medium 30 is smeared to the junction of the heat pipe 10a and the heat sink 20. A press mold 40a has a protrusion for the heat pipe 10a inside the groove 21. An end of the heat pipe 10a pointing out the groove will be pressed by the protrusion of the press mold 40a so as to be deformed and fit to the groove 21.

third embodiment

[0019]Referring to FIG. 3A to 3E, press fitting method for heat pipe and heat sink according to the present invention is illustrated. The embodiment includes the following steps.

[0020]a) At least one heat pipe 50 and a heat sink 60 conducting heat to the heat pipe 50 are provided. The heat pipe 50 is approximately oval-shaped. The heat sink 60 has a plurality of fin 61. The plurality of fin 61 has a through hole 62 for receiving the heat pipe 50.

[0021]b) The heat pipe 50 is placed into the through hole 62. A conductivity medium 70 is smeared to the junction of the heat pipe 50 and the through hole 62. A jig 80 passing through the fins is holding against one side of the heat pipe 50.

[0022]c) Another side of the heat pipe 50 against the jig 80 is pressed by a press mold 82. The heat pipe 50 being pressed is deformed towards the fins 61 so that the fins 61 and the heat pipe 50 will be tightly fit together (as shown in FIGS. 3D and 3E).

[0023]Referring to FIGS. 4A to 4D, the fourth embod...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Electrical conductivity | aaaaa | aaaaa |

| Shape | aaaaa | aaaaa |

| Heat | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com