Segmented ballast base support structure and rail and trolley structures for unstable ground

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

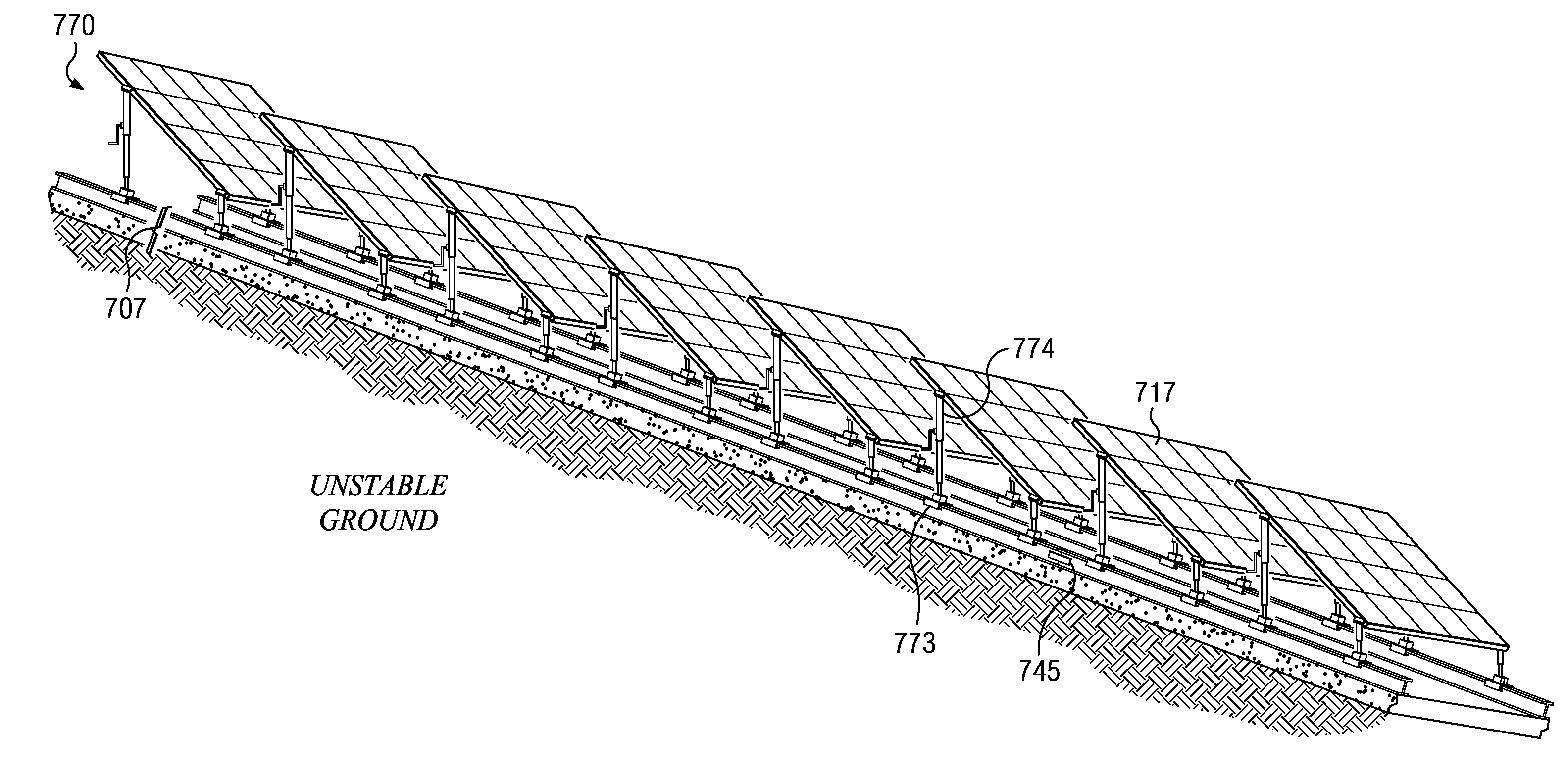

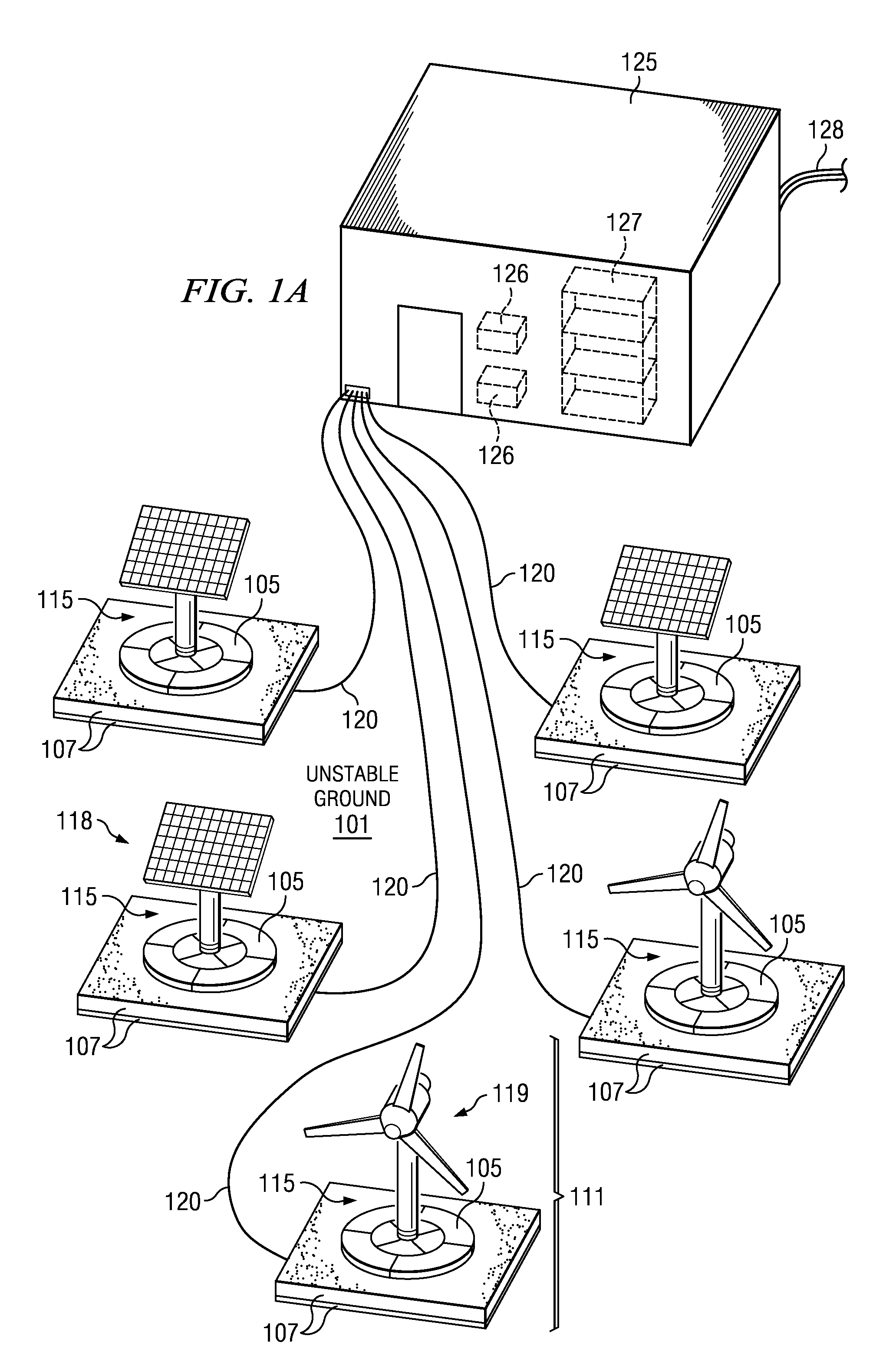

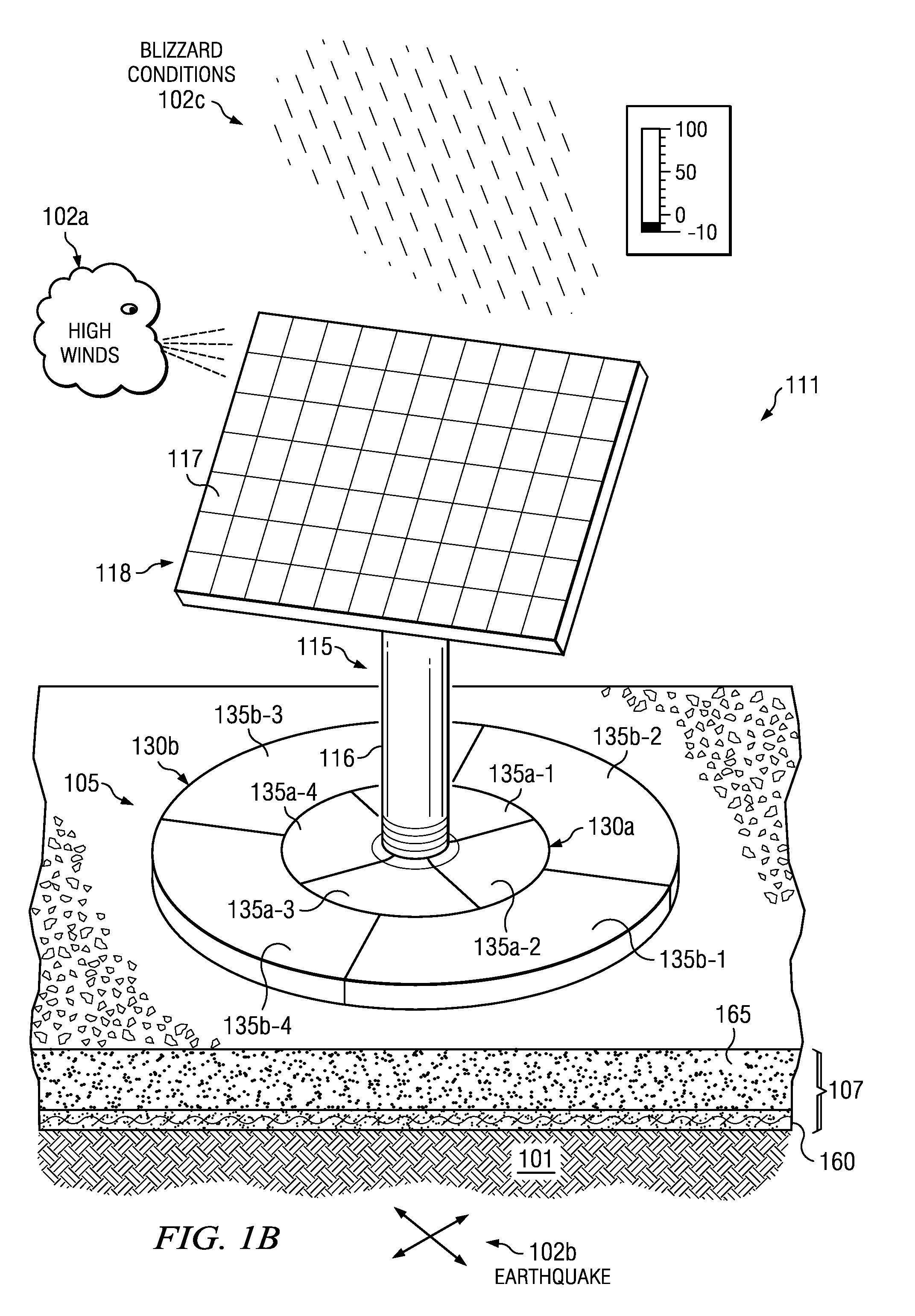

[0039]A description of example embodiments of the invention follows. Renewable energy refers to energy generated from natural resources, such as sunlight, wind, rain, tides, or geothermal heat, which are naturally replenished. Some renewable energy power generation technologies are criticized for being intermittent, unsightly, loud, and vast in size, yet the renewable energy market continues to grow. One environmental issue surrounding renewable energy power generation technologies is the large amount of land required to harvest energy, which otherwise can be used for other purposes. Embodiments of the present invention allow for renewable energy power generation devices (“power generation devices”) to be placed or built in areas that are away from view and otherwise are not usually built upon, such as landfills, brownfields, or Superfund sites.

[0040]Example embodiments of the present invention provide a support structure for such power generation devices that can be placed or built...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com