Solar collector for evaporation of aqueous solutions

a technology of solar collector and aqueous solution, which is applied in the direction of solar heat collector with working fluid, solar-ray concentration, sustainable buildings, etc., can solve the problems of large pond, large process, and high cost, and achieve the effect of reducing the mixing of layers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

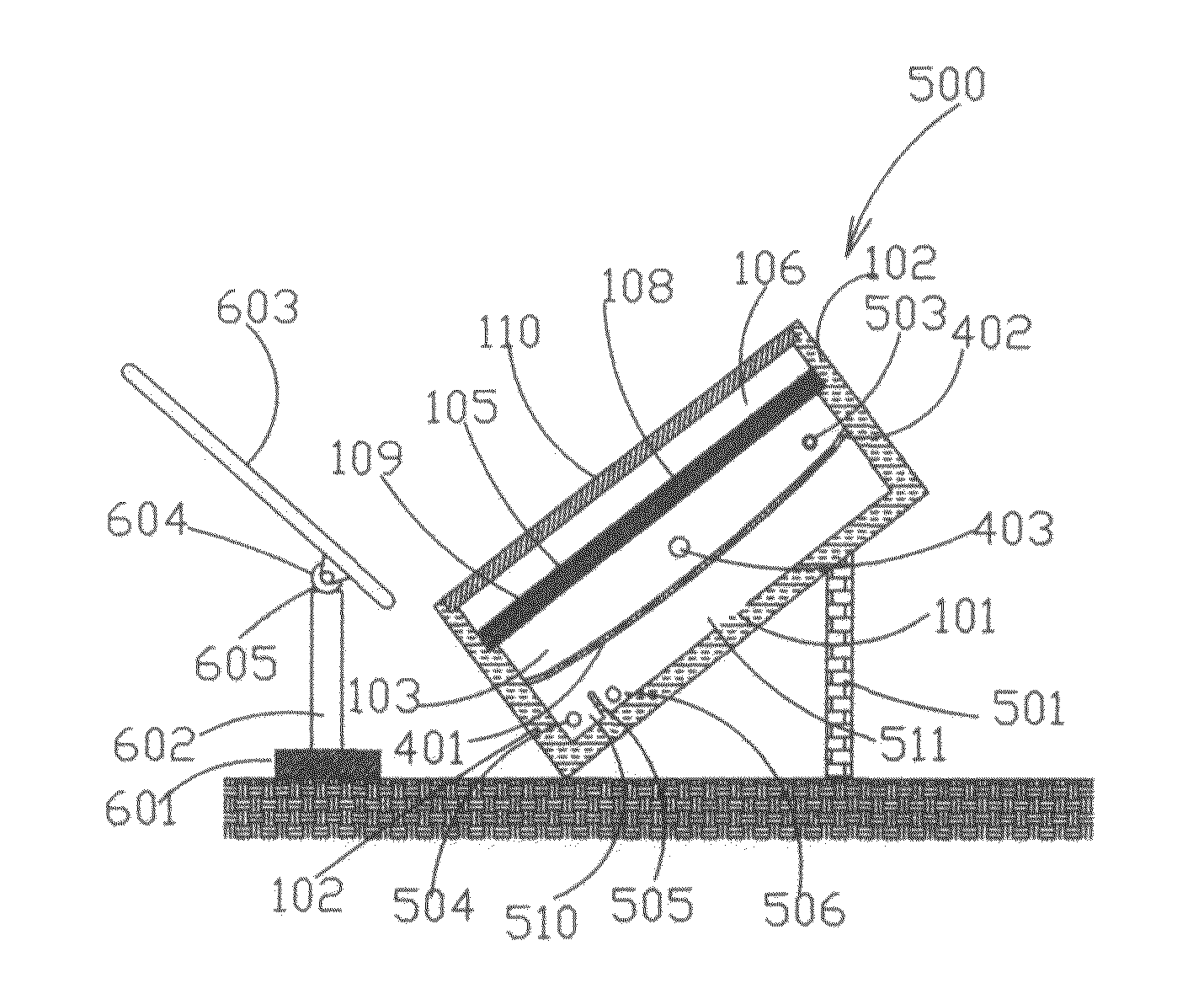

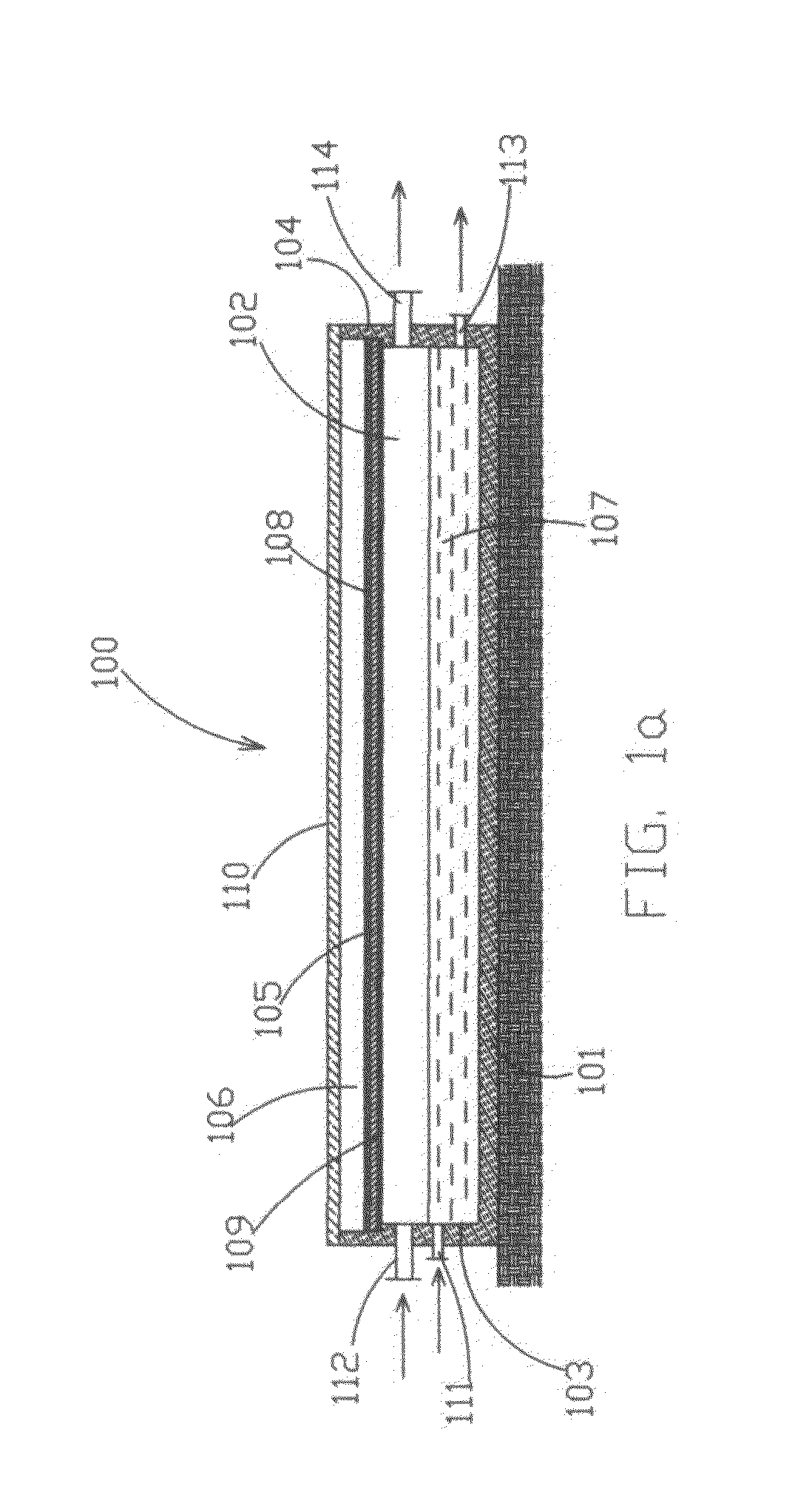

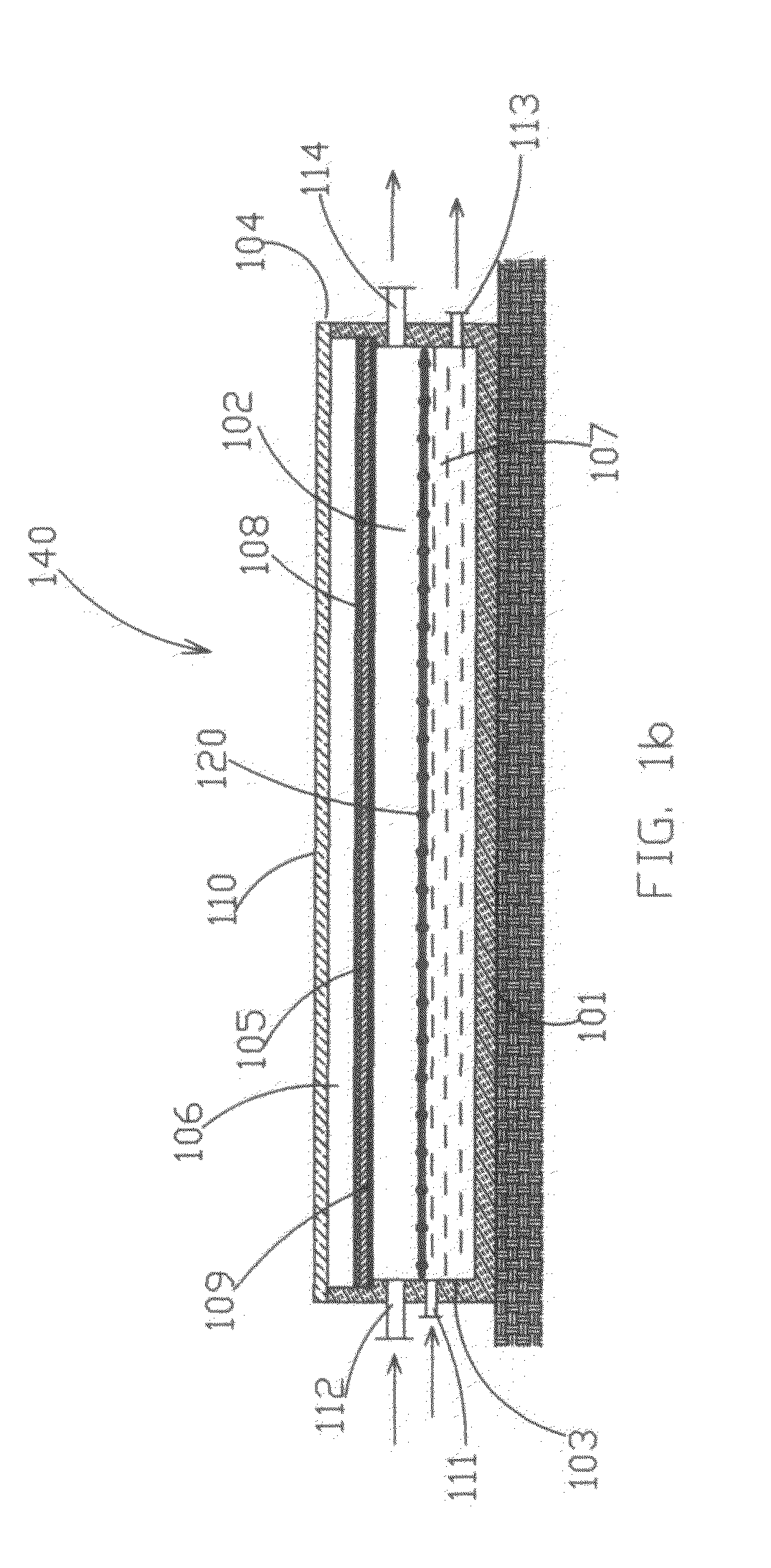

[0045]FIG. 1a shows a longitudinal vertical cross-section of a horizontal solar collector intended for concentration of aqueous solution.

[0046]It comprises a solar collector 100 in a form of a horizontal trough, which consists of in turn a base wall 101, sidewall 102 and two opposite end walls 103 and 104; the horizontal trough is divided by a metal horizontal sheet 105 into the upper section 106 and the lower section 107;

[0047]The upper side of the metal horizontal sheet 105 is provided with a selective coating 108 and the lower side of this metal horizontal sheet 105 is provided with coating 109 with high emittance in the infrared range of spectrum.

The upper section of the horizontal trough 100 is covered with glazing 110.

[0048]The lower section of the horizontal trough 100 is filled up to a certain level with the aqueous solution to be partially evaporated;

[0049]The first end wall 103 is provided with two inlet connections 111 and 112 for supply the aqueous solution to be partial...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree angle | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| pressure | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com