Apparatus for aerohydrodynamic abrasive cleaning of surfaces, sprayer for the same, and method for aerohydrodynamic abrasive cleaning of surfaces

a technology of aerohydrodynamic abrasives and sprayers, which is applied in the direction of abrasive equipment, metal-working equipment, manufacturing tools, etc., can solve the problems of low cleaning quality, disadvantage of prior art equipment, and disadvantage of art sprayers, so as to improve the uniformity of abrasive material grains, improve the efficiency of cleaning, and improve the effect of cleaning quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

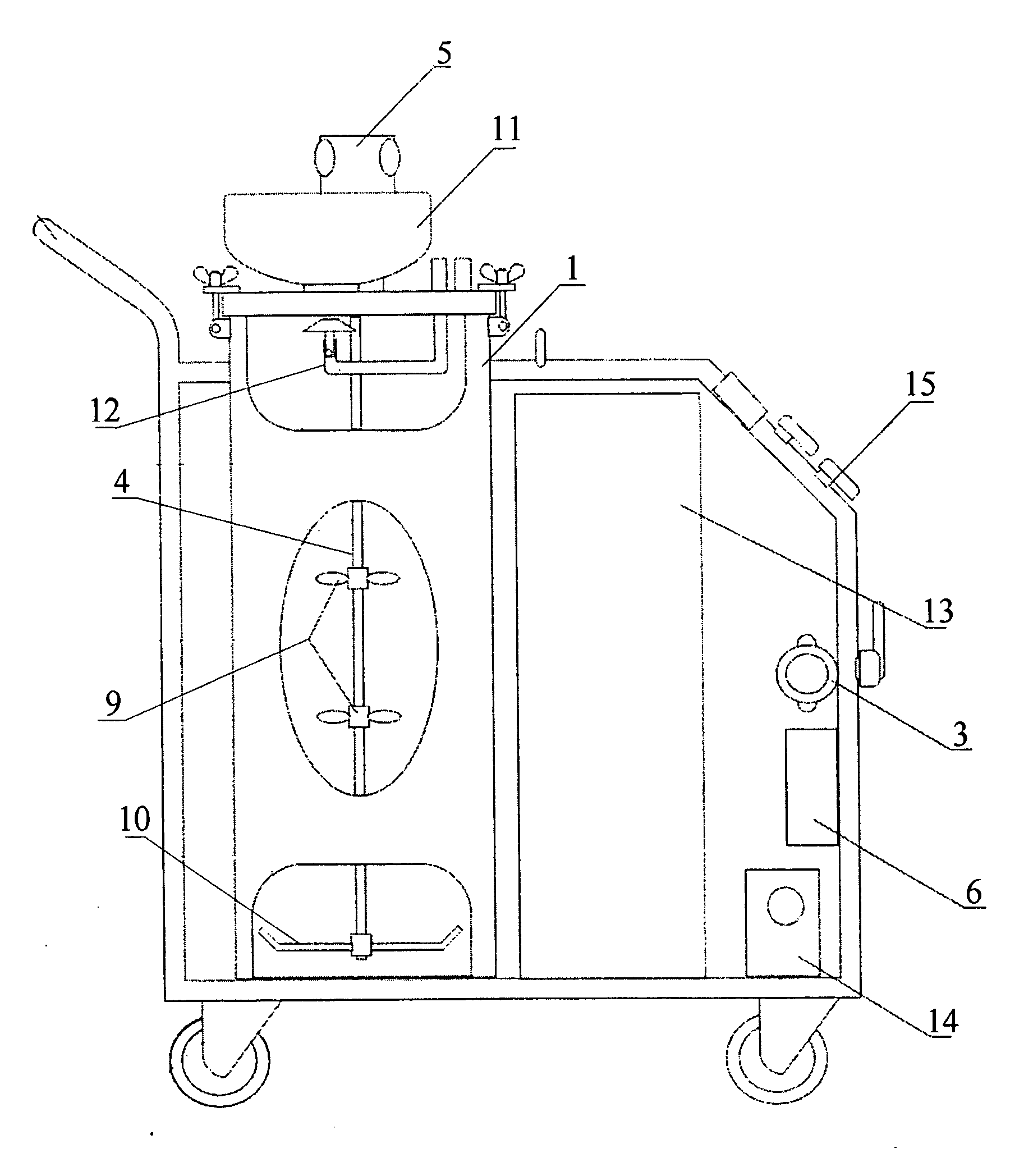

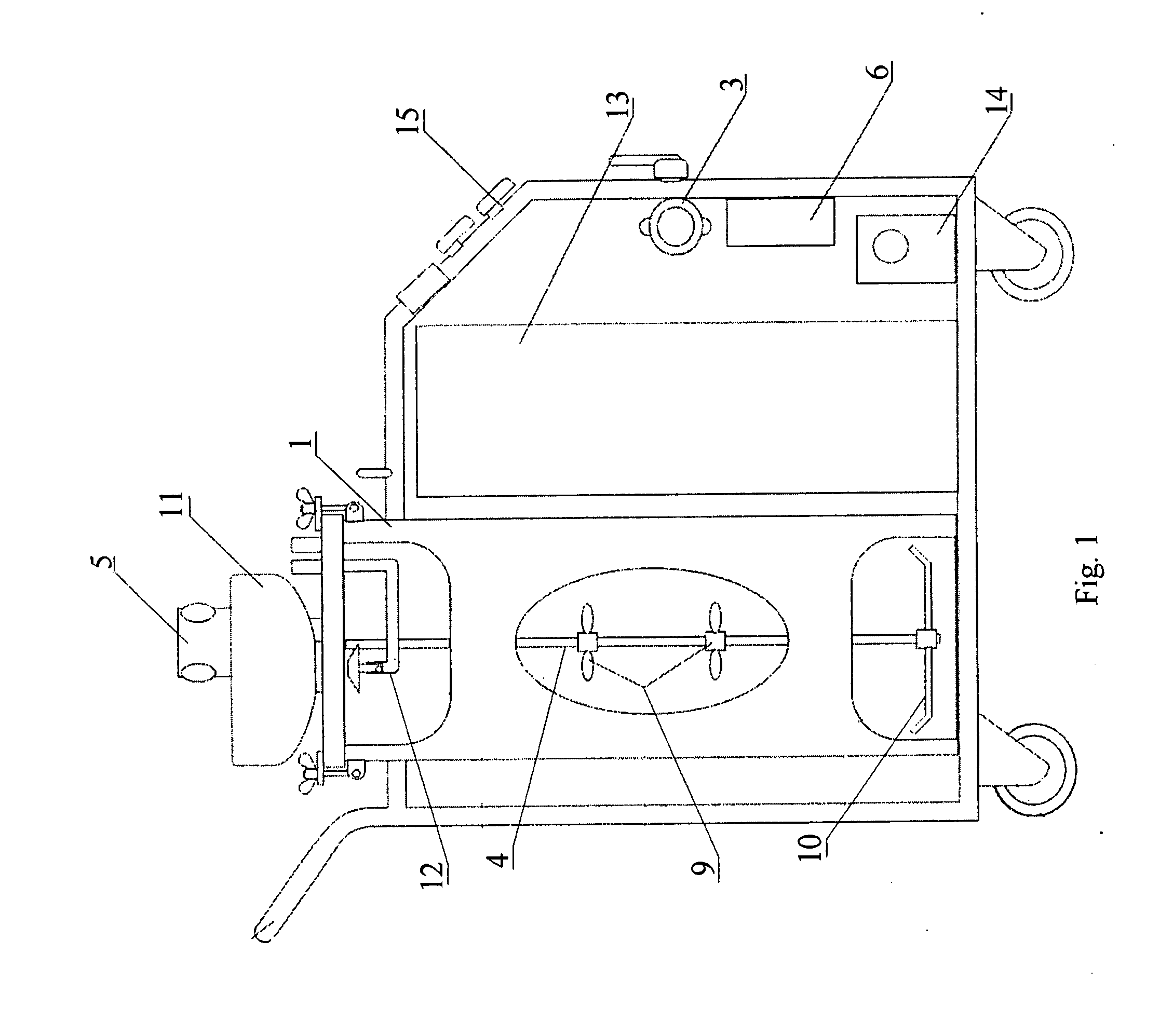

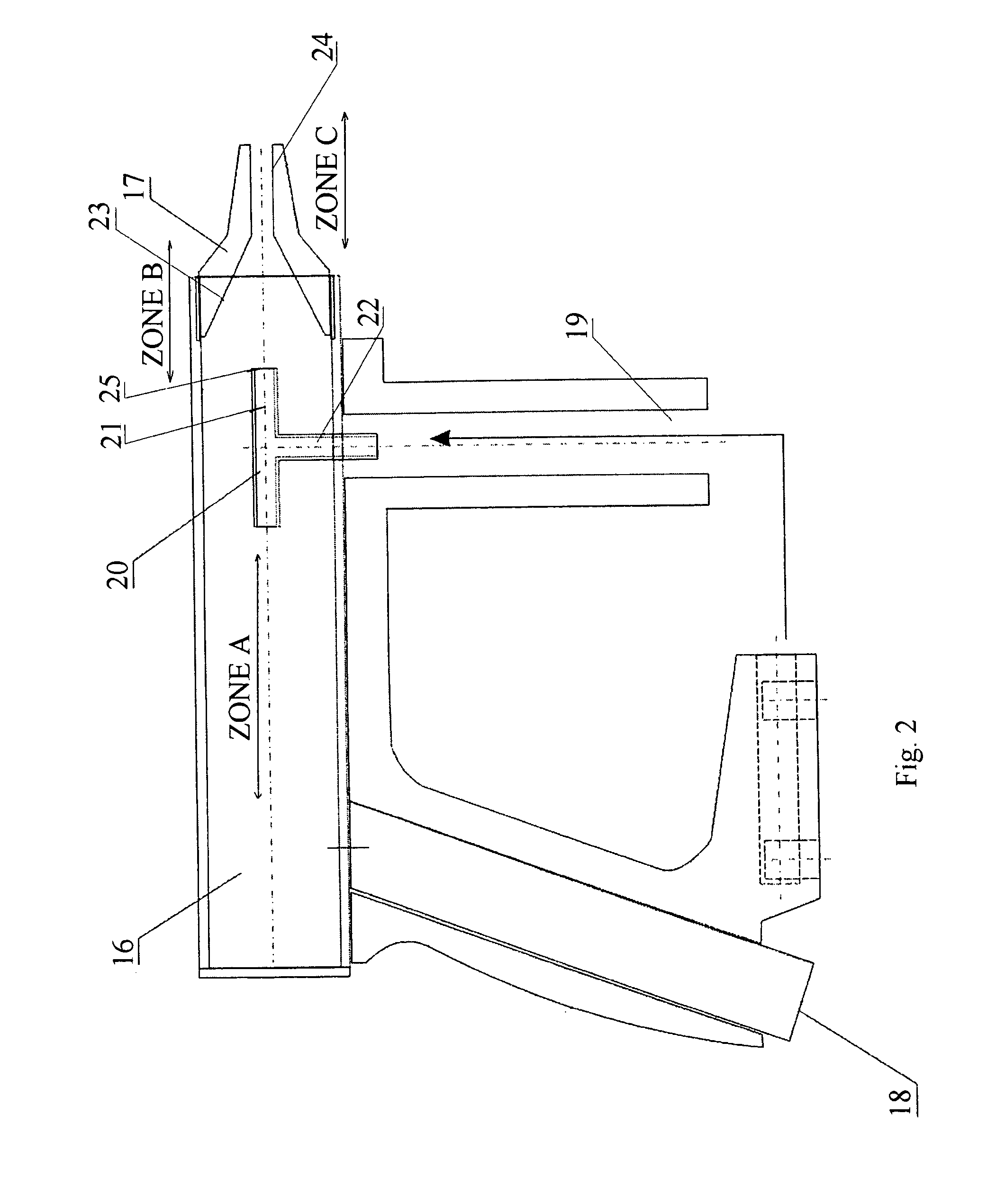

[0029]The apparatus for aerohydrodynamic abrasive cleaning of surfaces (see: FIG. 1 and FIG. 3) comprises a container 1 for preparing abrasive suspension that includes a stirring mechanism and a sprayer 2 for spraying the abrasive suspension connected to container 1 and a compressed gas supply device 3.

[0030]The stirring mechanism comprises a stirrer 4 and an air motor 5 associated therewith and connected to a compressed gas supply device 3 through an air preparation unit 6 that includes a drier 7 and a lubricant supply device 8. Stirrer 4 is provided with blades 9 and a comminuting cutter 10 provided thereon in the bottom part of container 1.

[0031]Stirring container 1 is provided with a filling funnel 11 having a locking device 12.

[0032]The apparatus has a washing liquid container 13 connected to sprayer 2 through an air pump 14 connected to compressed air supply device 3 through air preparation unit 6.

[0033]The apparatus units are interconnected by hoses provided with valves 15, w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

| Mass | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com