Improved laces for use with footwear, sports equipment and the like

a technology for sports equipment and laces, applied in the direction of braids, monocomponent polyester artificial filaments, applications, etc., can solve the problems of inoperable footwear or sports equipment, and achieve the effects of reducing friction, reducing friction, and reducing friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012]The present invention provides laces for footwear or sporting equipment comprised of liquid crystal polymer (LCP) fibers. LCP fibers have much higher tension stiffness than conventional fibers used in laces. They are also significantly stronger than conventional fibers. An example of liquid crystal polymer (LCP), also known as aromatic polyester, is the product produced and sold under the trademark VECTRAN by Kuraray America.

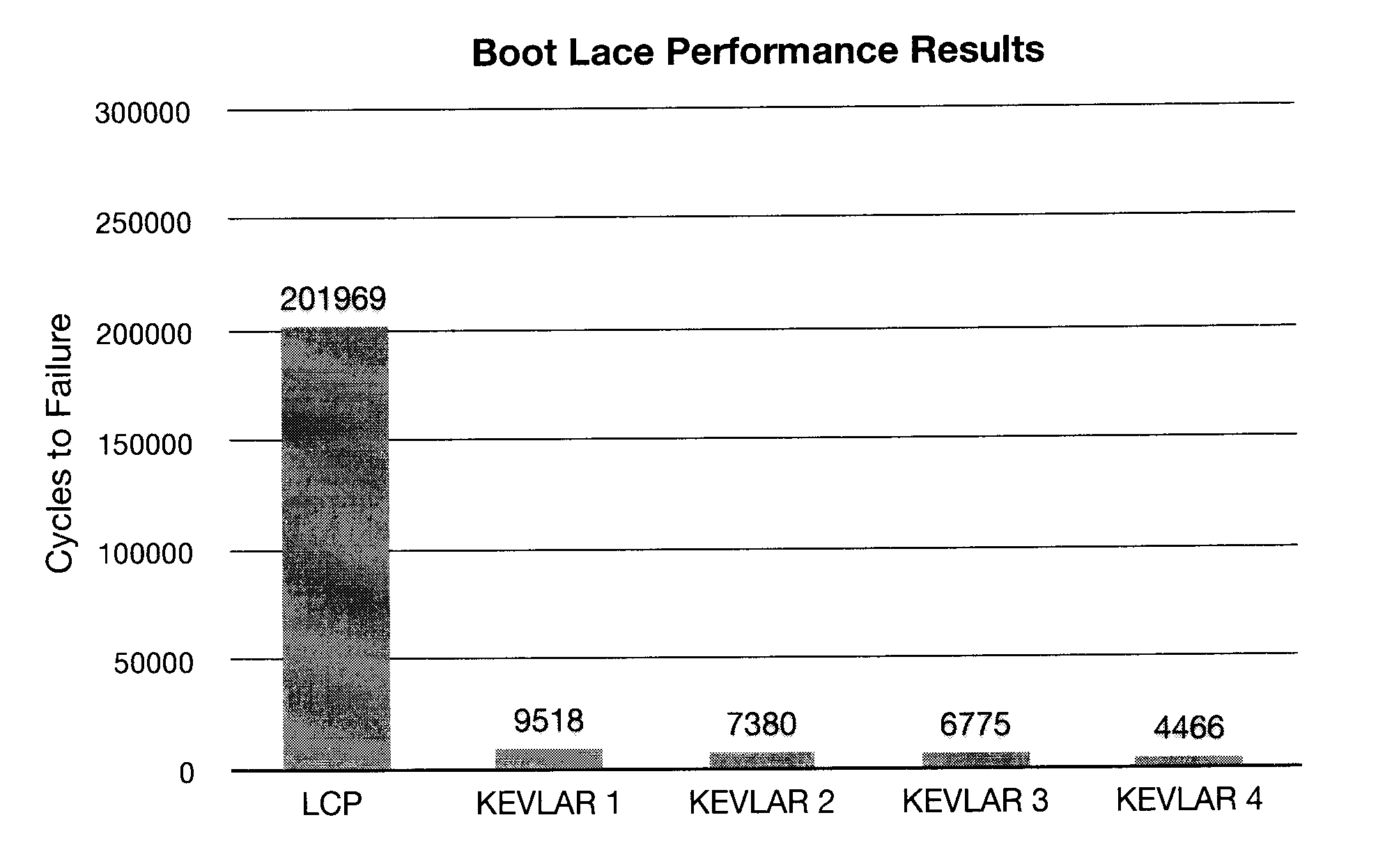

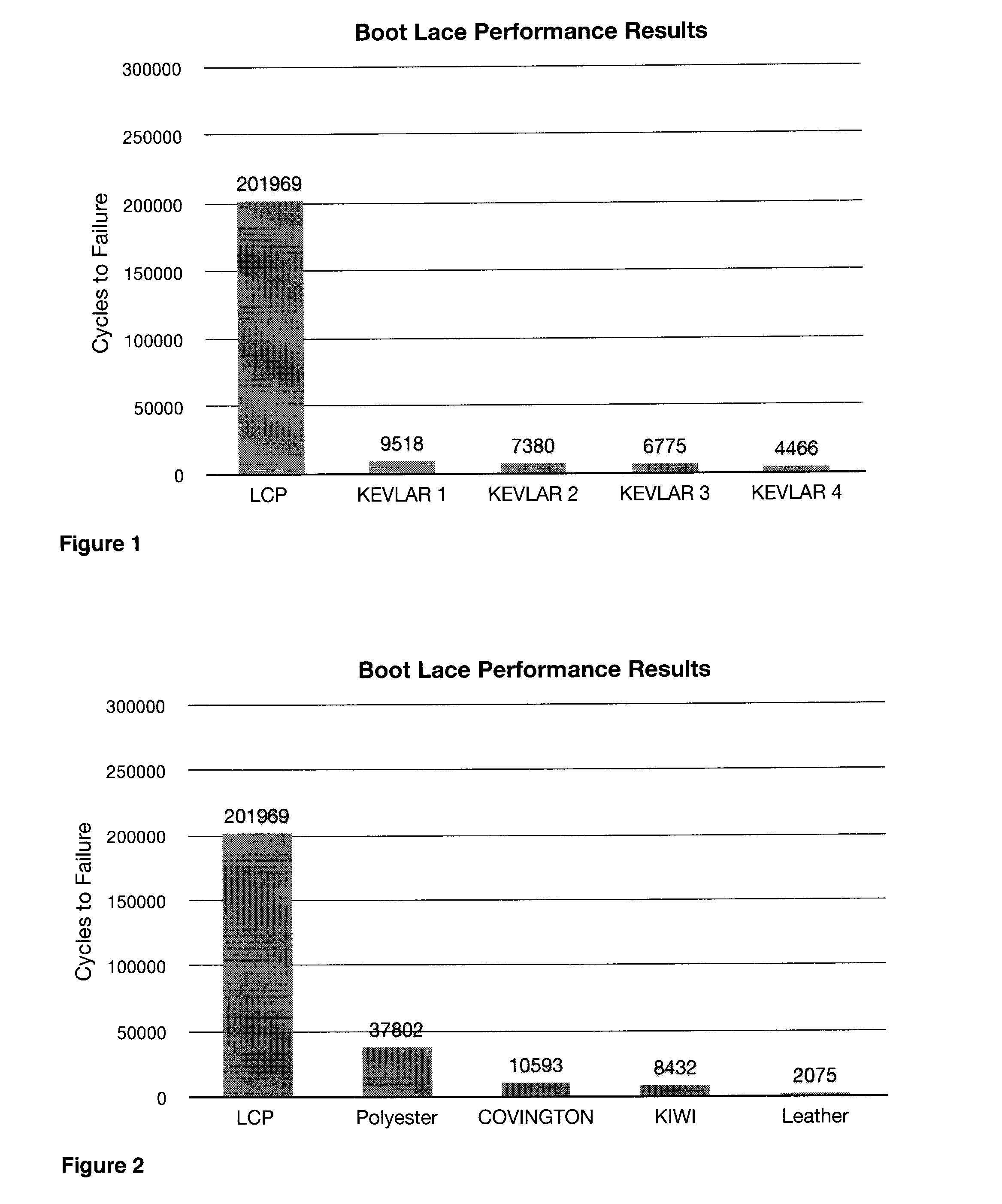

[0013]It was surprisingly discovered in laboratory performance tests on laces made of LCP fiber and on commercially available laces made of polyester and aramid fibers (KEVLAR), that the LCP fiber laces lasted at least five times longer than the best polyester fiber laces, and about twenty times longer than the best aramid fiber laces.

[0014]The LCP fiber laces in the tests were solid braid construction. In solid braid construction, all of the strand carriers on the braider move in the same direction. A strand moves under another, moves to the side in the i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| weight | aaaaa | aaaaa |

| weight | aaaaa | aaaaa |

| radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com