Orientation insensitive refrigerant distributor tube

a technology of refrigerant distributor and orientation-sensitive, which is applied in the direction of indirect heat exchanger, lighting and heating apparatus, stationary conduit assembly, etc. it can solve the problems of poor refrigerant distribution uneven temperature distribution over the coil, and mal-distribution of refrigerant through the refrigerant tube, etc., to achieve improved heat transfer efficiency and improved refrigerant distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

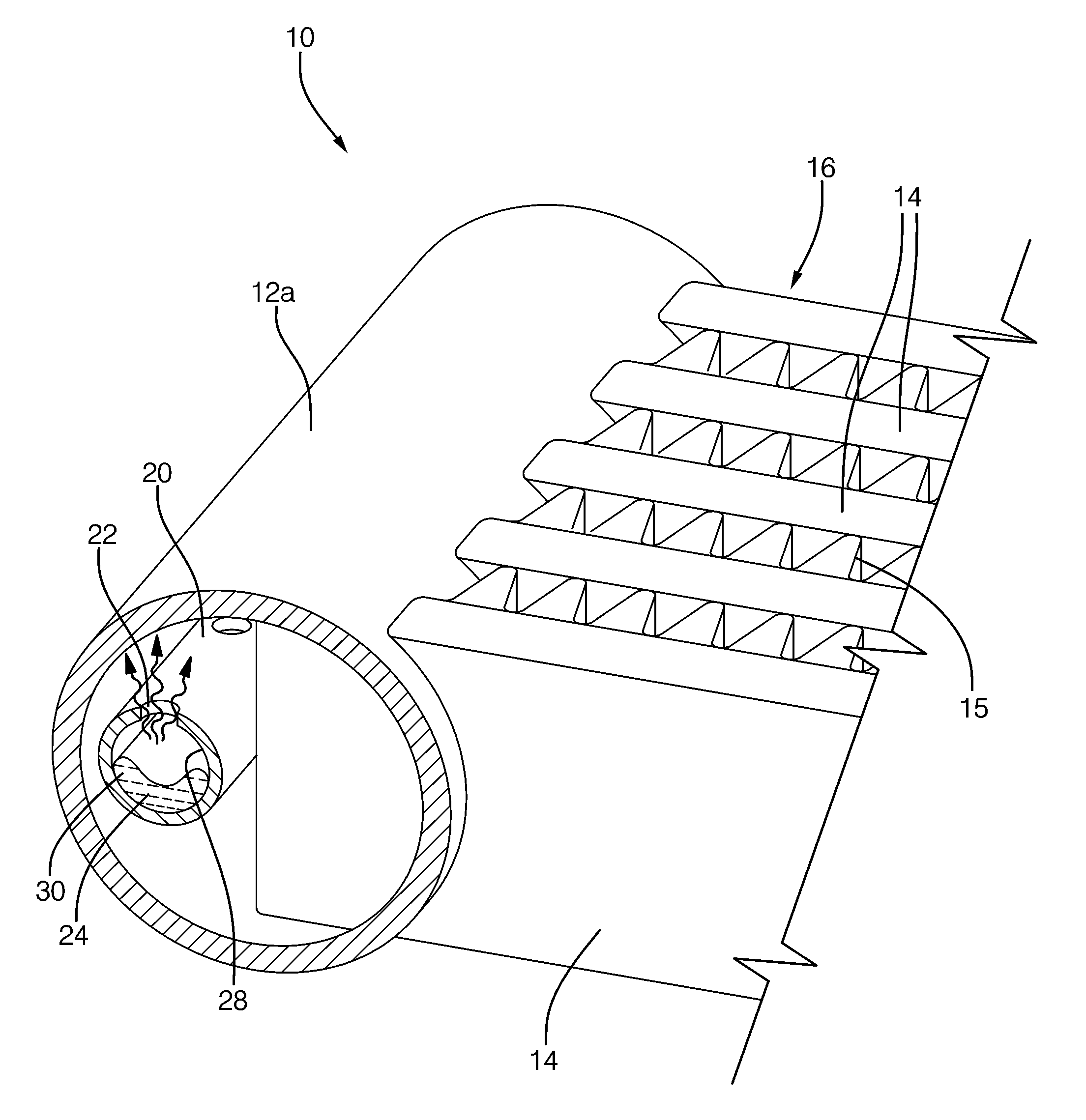

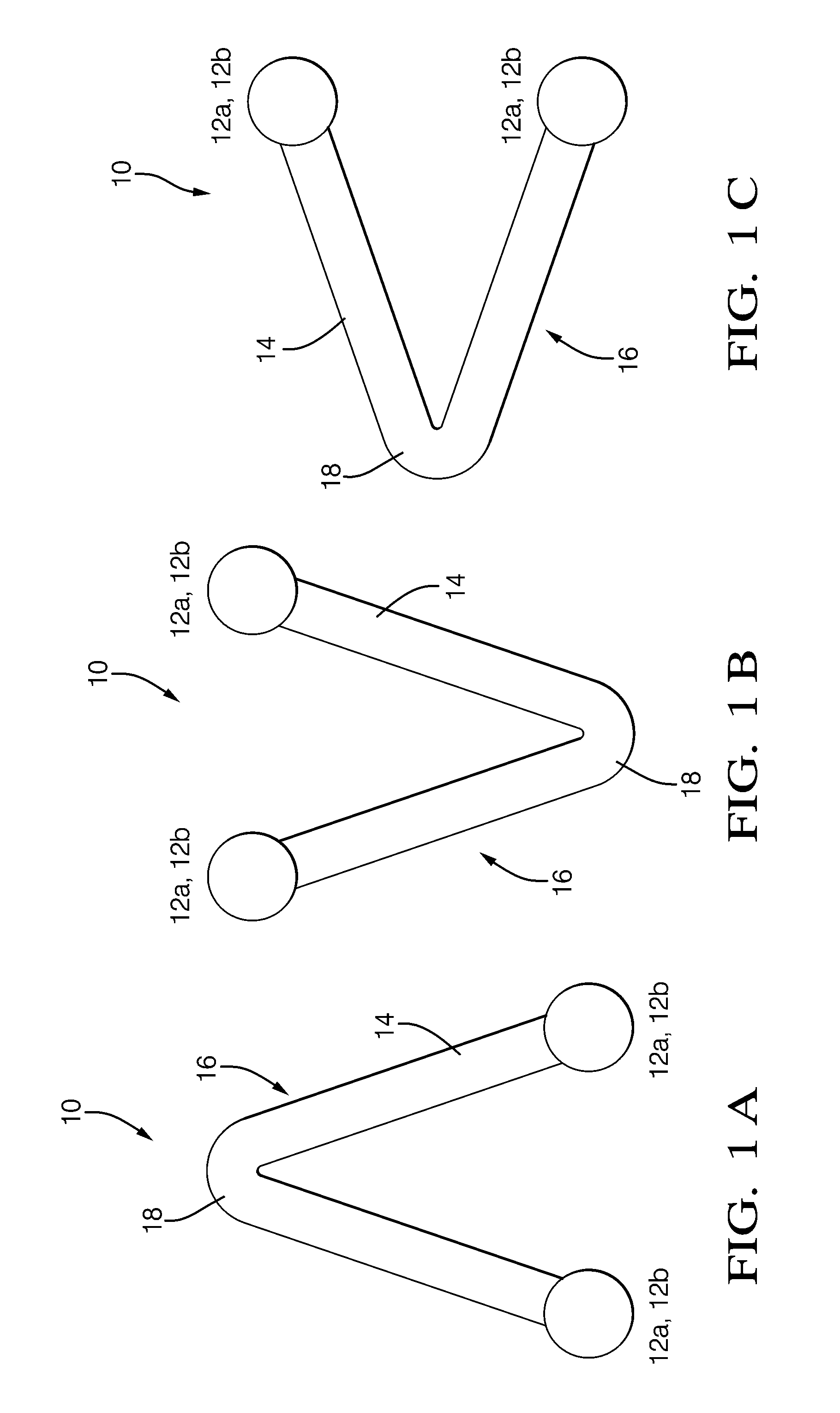

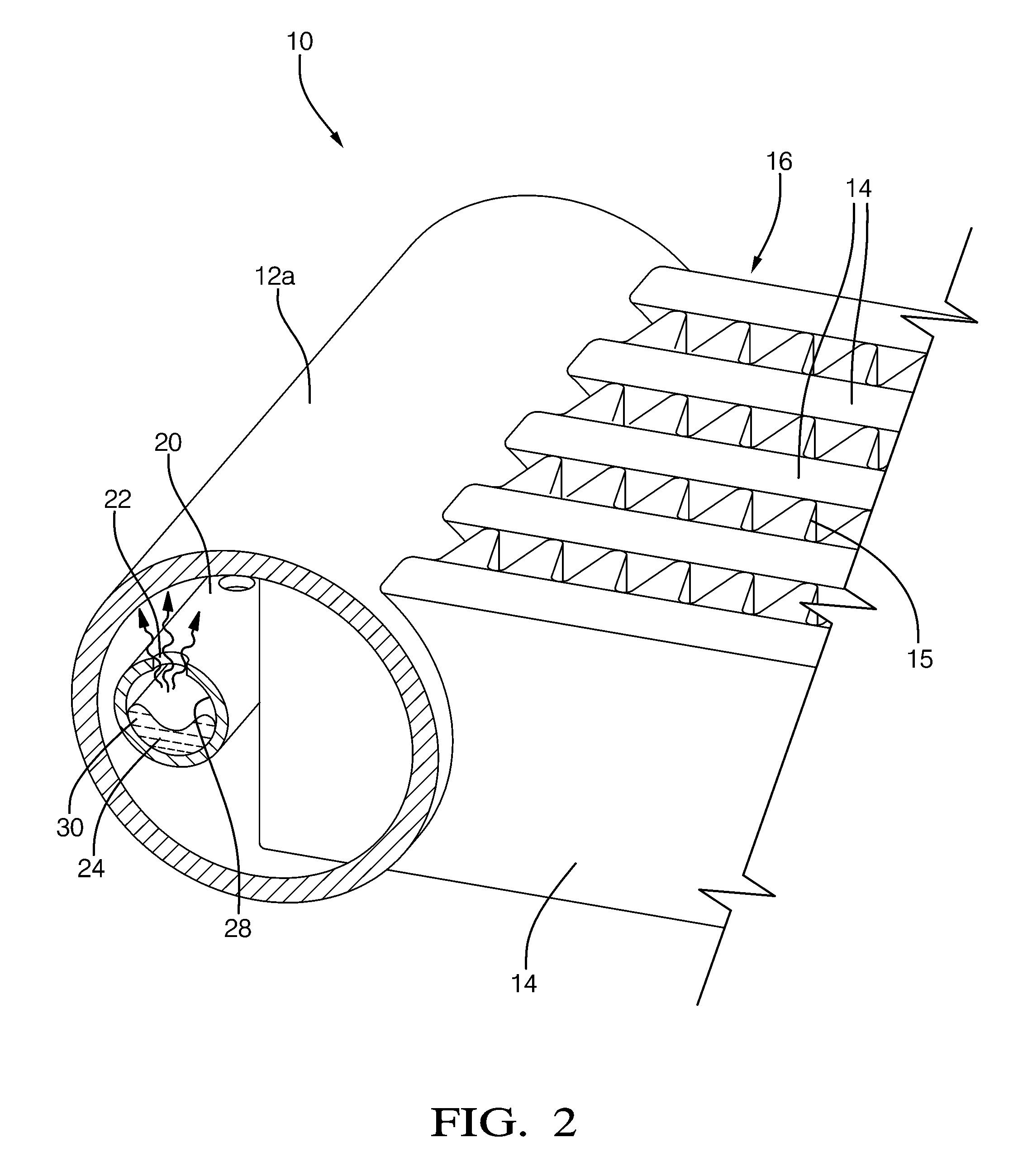

[0019]For a typical slab coil design evaporator, the desired angle of the orifices of a distributor tube is selected based on testing of a vertical slab coil in which the refrigerant tubes are aligned in the direction of gravity with the inlet header lower than the outlet header. To accommodate the packaging constraints required for residential applications, a residential indoor evaporator may be constructed by using two slab coils in an A-Frame design or a single slab coil bent into an ARC design. Shown in FIGS. 1A-1C are representations of an end view of an A-Frame design or ARC design residential indoor evaporator 10 having an inlet header 12a, an outlet header 12b spaced apart from the inlet header 12a, and a plurality of refrigerant tubes 14 hydraulically connecting the headers 12a, 12b for refrigerant flow. An evaporator coil 16, partially shown in FIGS. 2 and 3, is defined by the plurality of refrigerant tubes 14 together with external fins 15 interconnecting the adjacent ref...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com