Pipeline instrumentation and control system

a technology of instrumentation and control system and pipeline, which is applied in the direction of transmission, fluid removal, survey, etc., can solve the problems of system interference, high requirement for providing such information, and difficult task of extraction of hydrocarbons from well system, and achieve the effect of efficient communication link

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

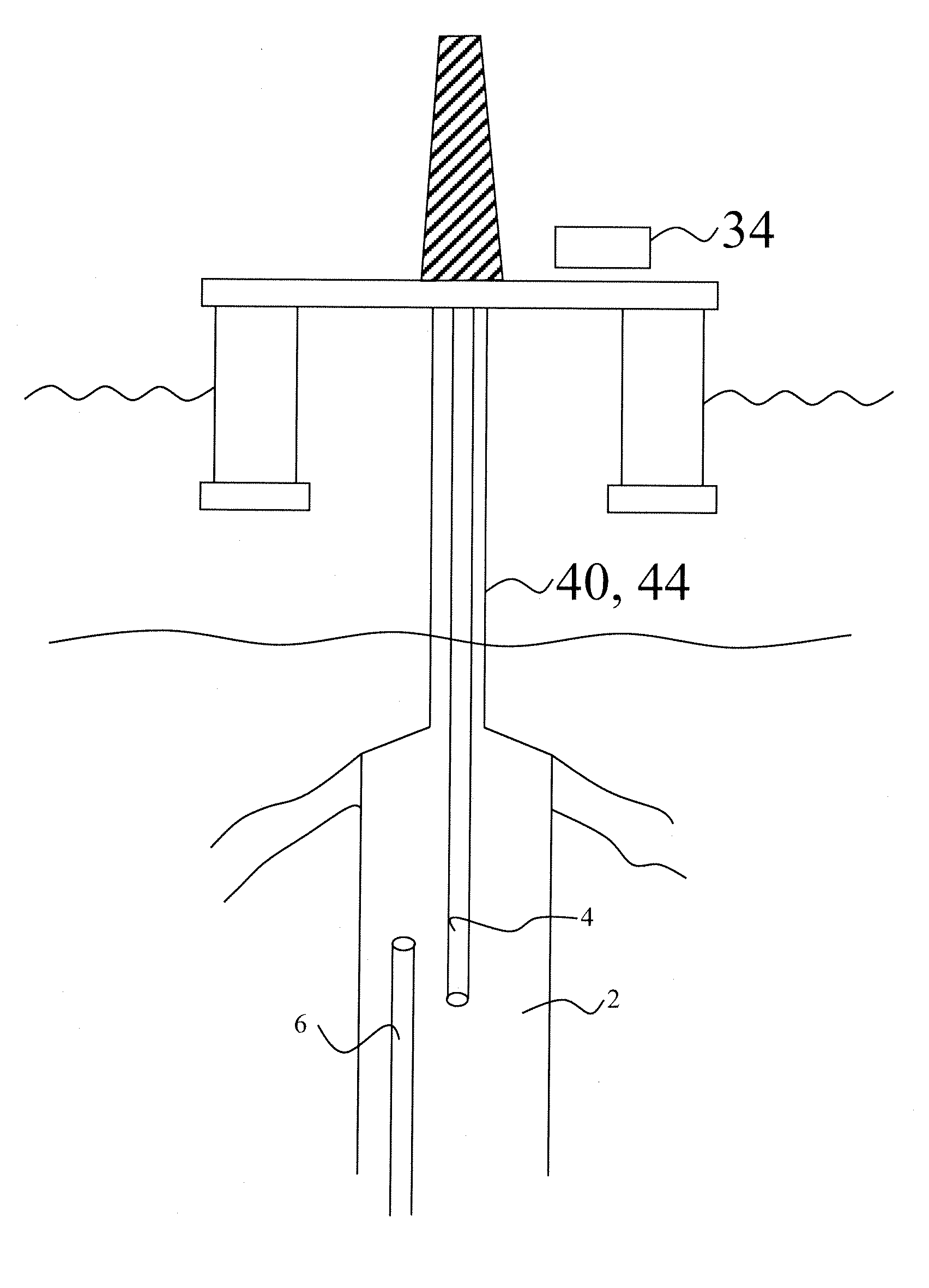

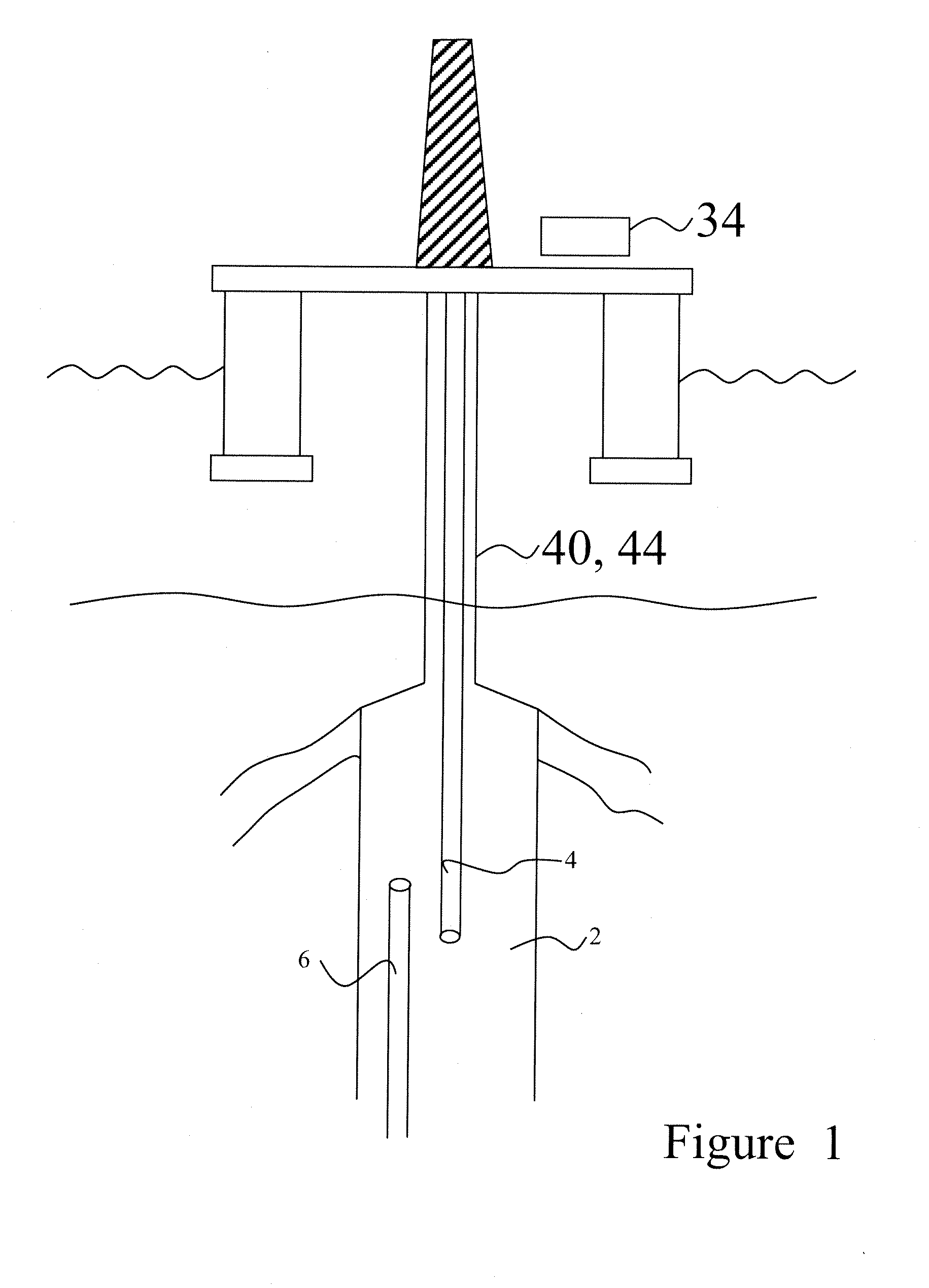

[0043]FIG. 1 shows a simplified view of a radiating cable system of the present invention arranged within a production tubing of a hydrocarbon extraction facility. The radiating cable system 2 comprises a first radiating cable 4 and a second radiating cable 6 made generally of a first and second elongated radiating co-axial axially extending cable. First and second radiating cables 4, 6 are generally flexible in nature and as will described later for allowing general manipulation during insertion and removal into and out of hydrocarbon production tubing. In the current application, a radiating cable is defined as controlled radiation of a signal passed along the length of a cable. In one example embodiment a first elongated radiating cable for coupling signals to a second radiating cable has its shield formed by winding a conductive tape in a helical arrangement with slots between turns to allow controlled leakage of signals as it propagates along the cable.

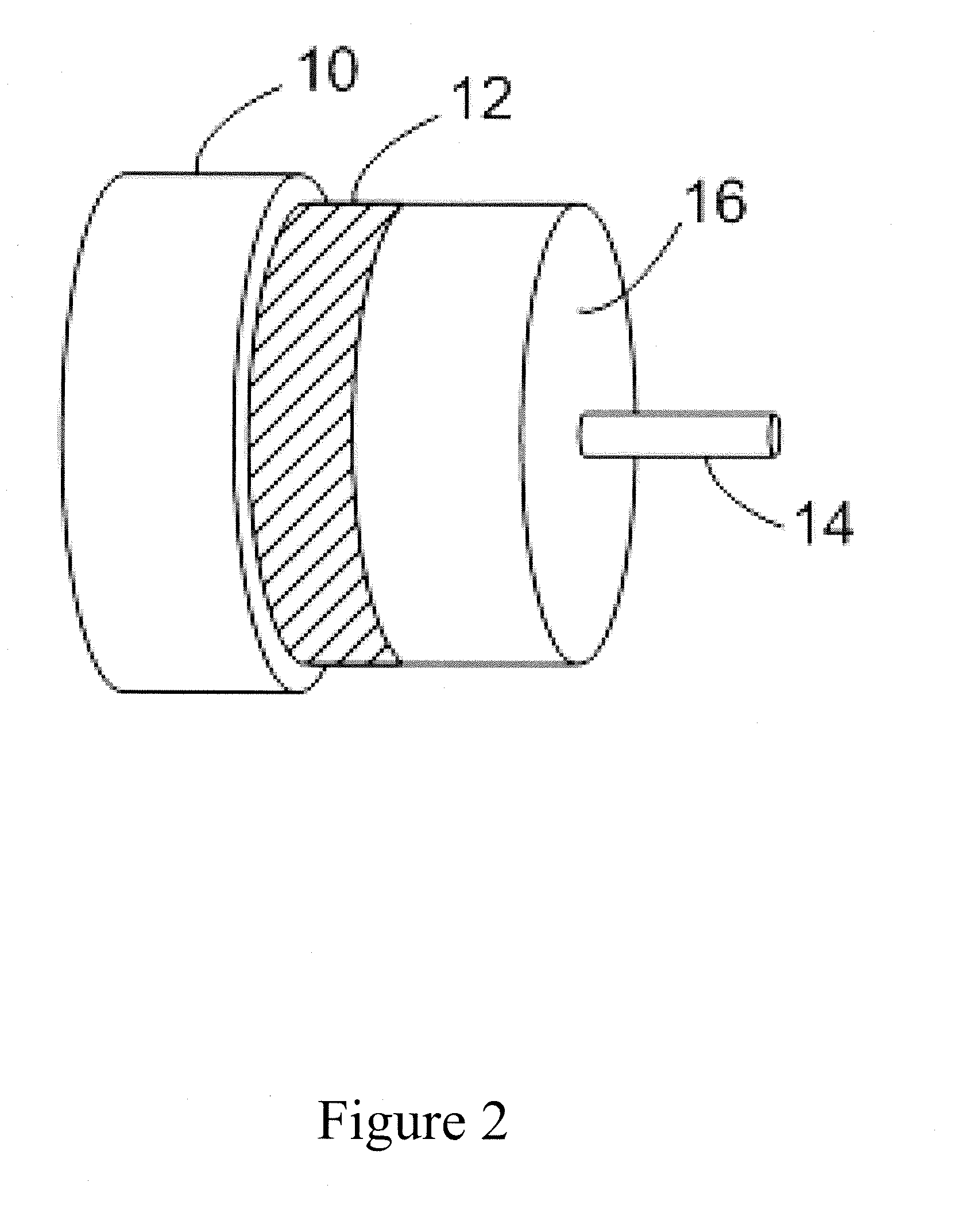

[0044]Similarly, second r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com