Method of Simultaneously Drying Coal and Torrefying Biomass

a technology of biomass torrefaction and coal drying, which is applied in the direction of biofuels, fuels, waste based fuels, etc., can solve the problems of increasing the transport cost of materials, not addressing product cooling, and process is often not as efficient, so as to improve the distribution of water added

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

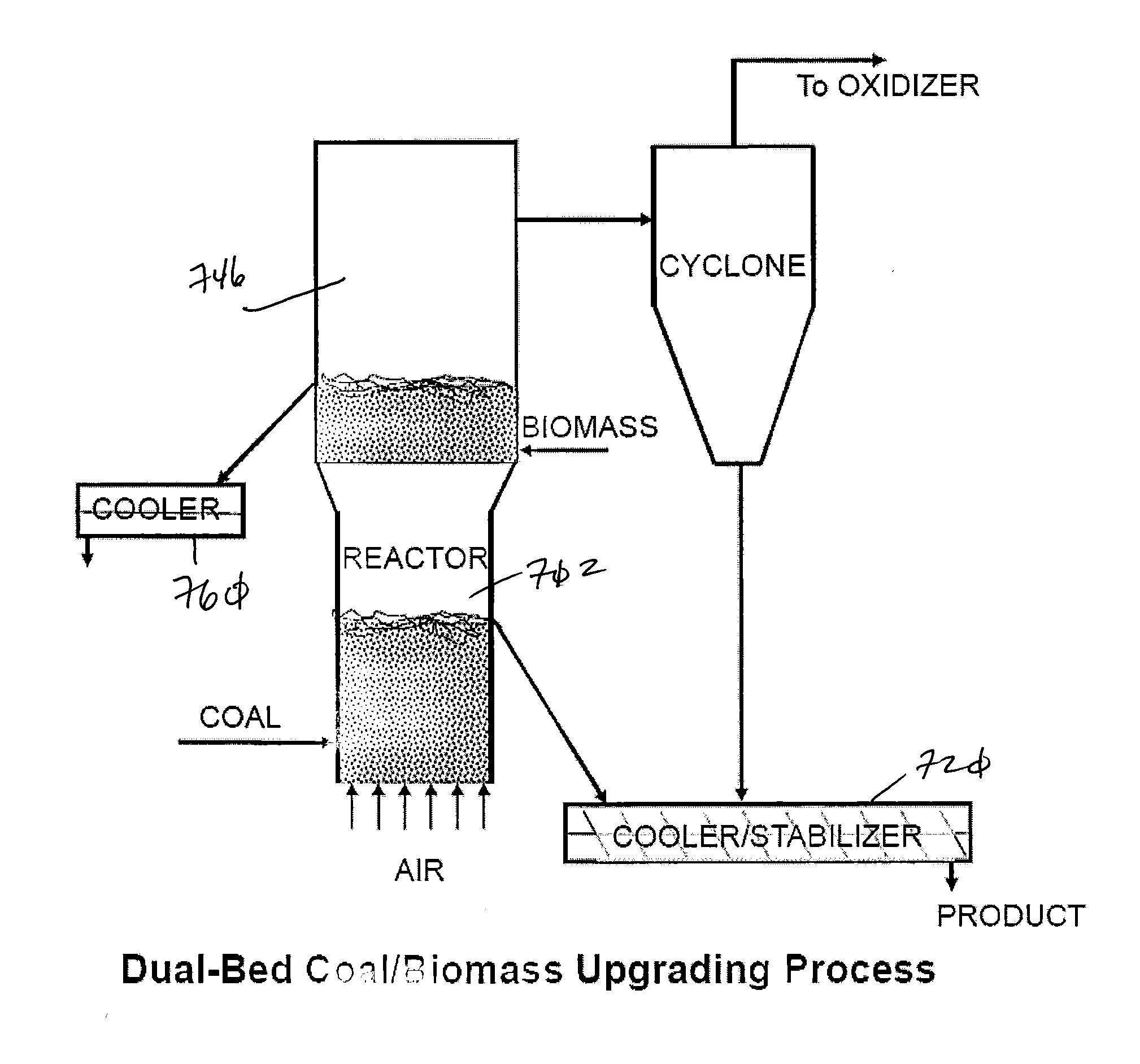

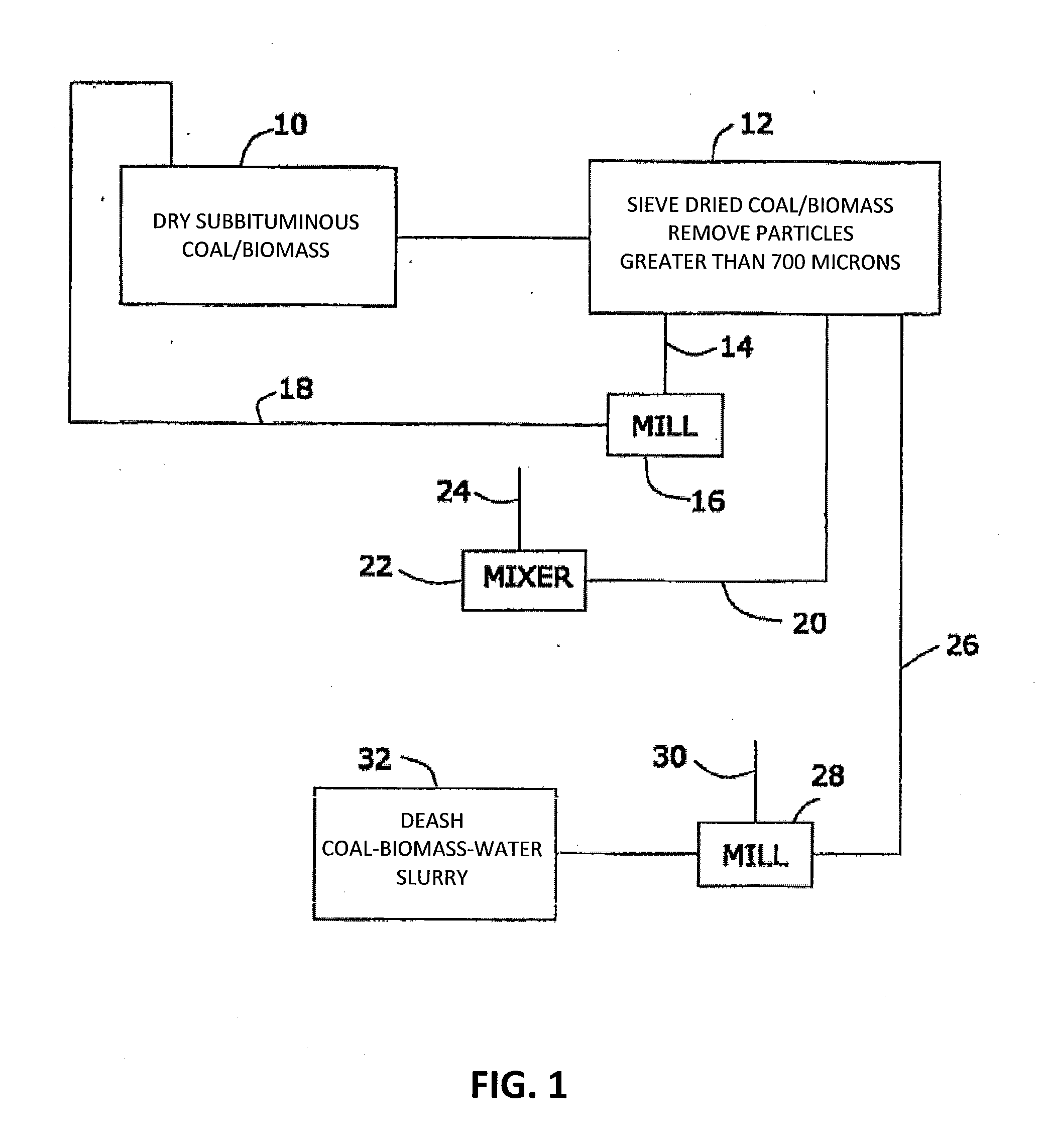

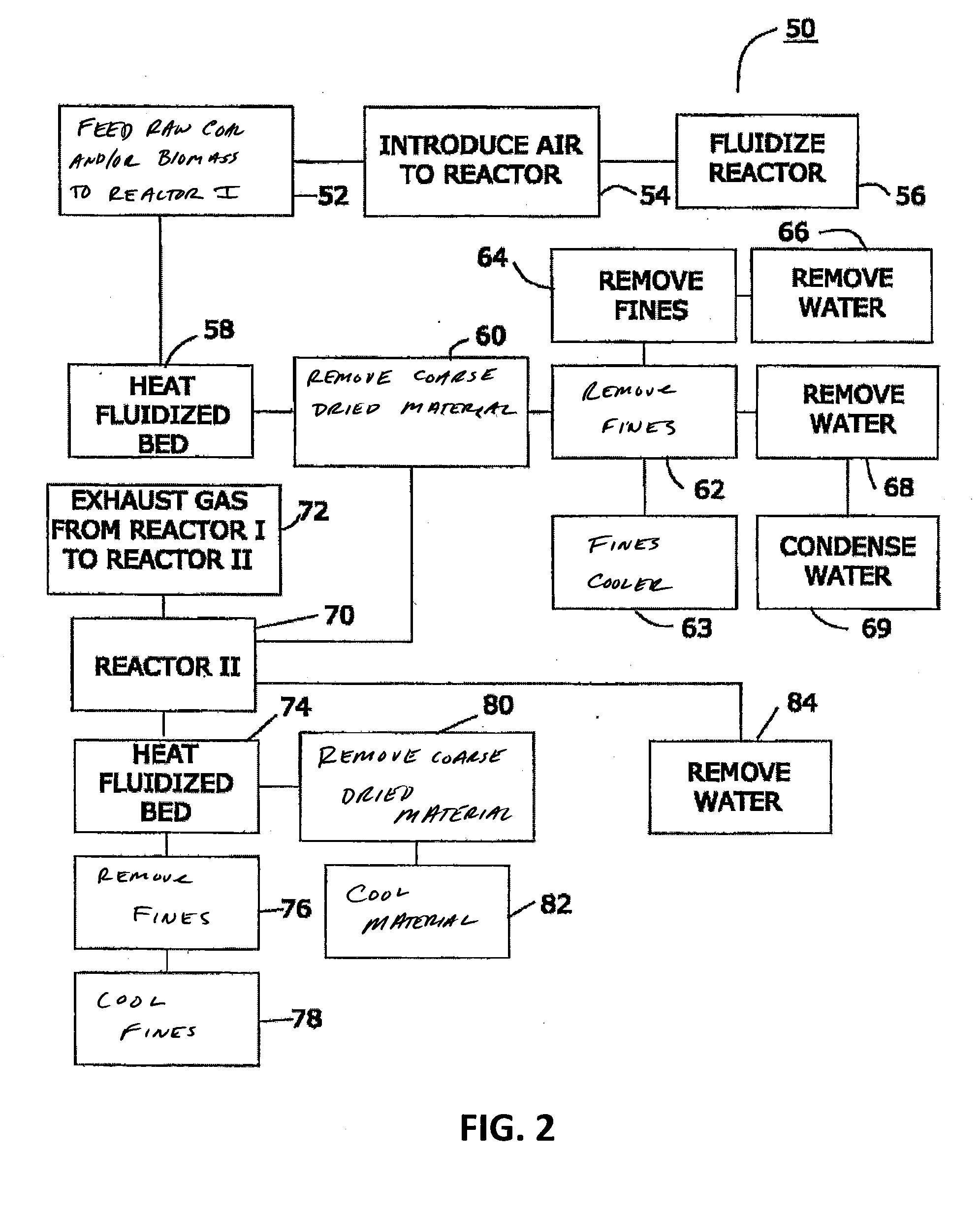

[0038]Referring now to FIGS. 1 and 2, a process for preparing a coal-biomass-water slurry and drying the same is shown. In order to remove water from coal and / or biomass, drying processes have been employed that utilize fluidized bed reactors. A fluidized bed reactor is a system wherein a fluid or gas is passed through a granular solid material at high velocities to suspend the solid and cause it to behave as if it were fluid (i.e. fluidization). In one embodiment, the coal used in the process of this specification is similar to the coal having about 5 to about 30 weight percent of moisture and, more preferably about 10 to about 30 weight percent of moisture. The biomass is similar to biomass having about 10 to 50 weight percent moisture. However, in the instant case, the coal used may often contain up to about 40 weight percent of water. The moisture content of coal and / or biomass may be determined by conventional means in accordance with standard A.S.T.M. testing procedures. Metho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com