Hydroprocessing process for the improvement of the catalyst life

a catalyst and hydroprocessing technology, applied in the direction of hydrocarbon oil cracking, aromatic hydrocarbon hydrogenation, fuels, etc., can solve the problems of carbon monoxide and carbon dioxide generation, and achieve the effects of reducing long term deactivation, prolonging life, and improving catalyst li

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

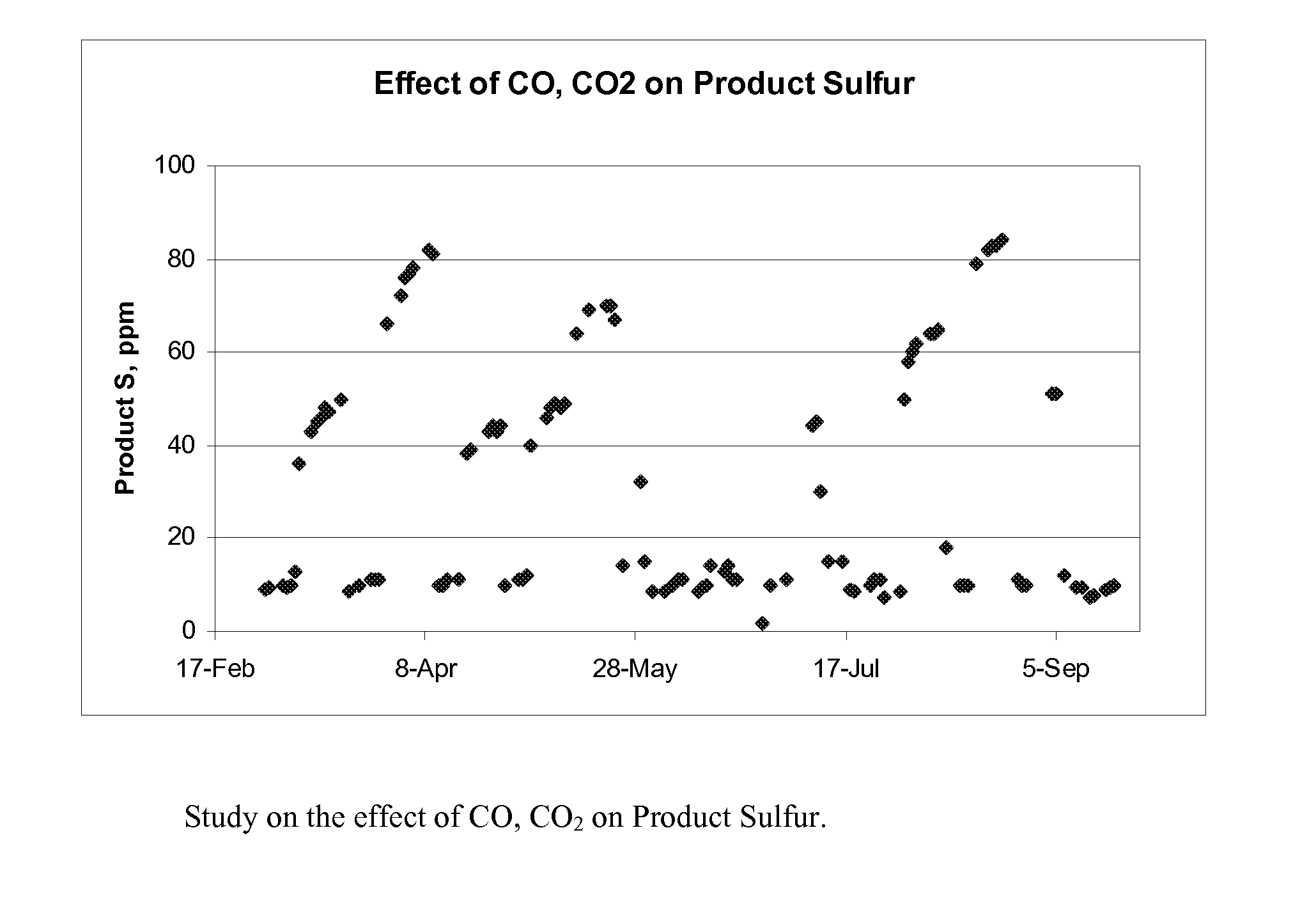

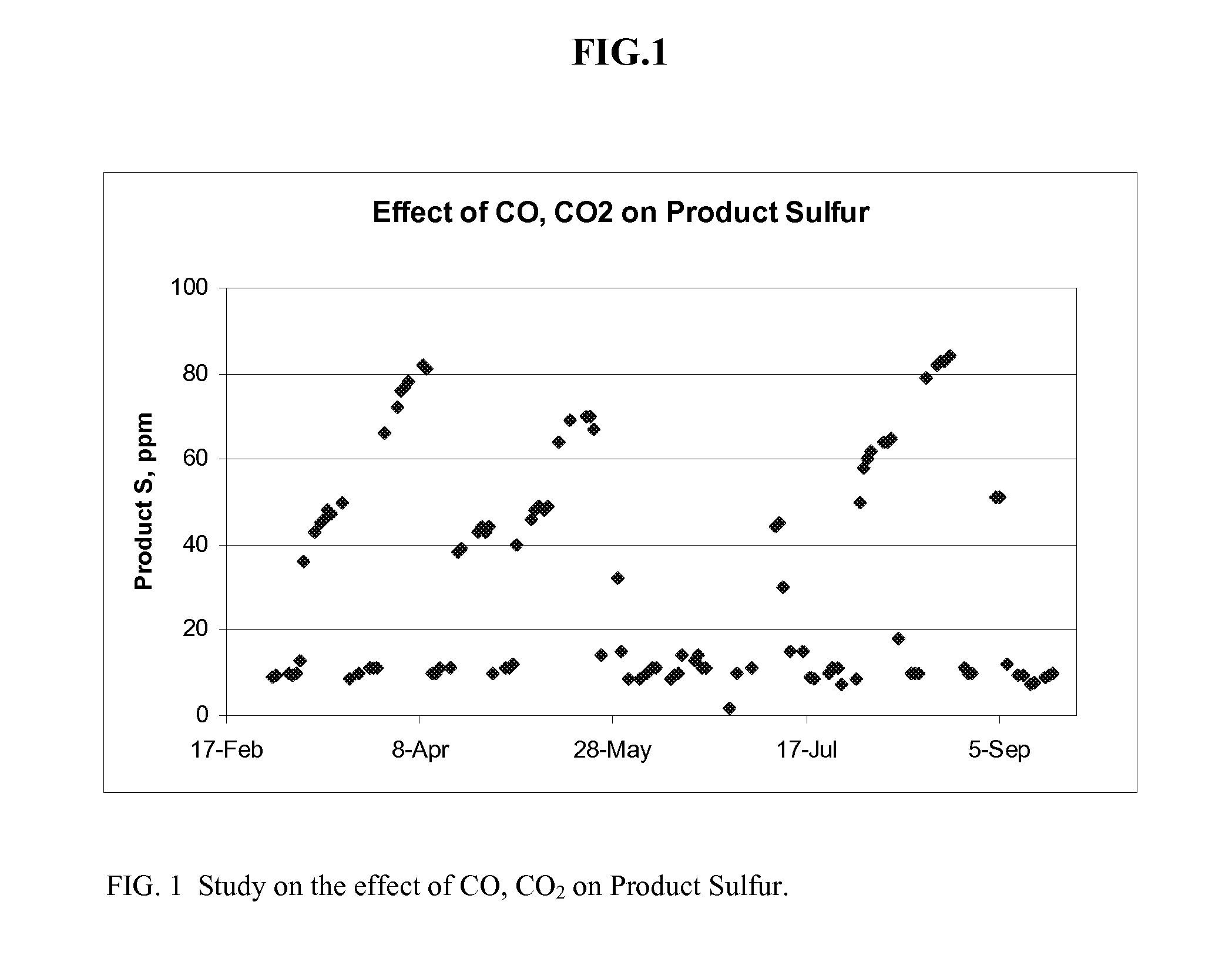

[0032]Laboratory and commercial tests have demonstrated that vegetable oils and / or animal fats can be added to a refinery hydrotreater to produce transportation fuels. Since carbon monoxide and carbon dioxide can be generated from oxygen containing feedstocks such as animal fat and vegetable oils in this hydrotreating process, experiments were run to study the effects that CO and CO2 would have on the performance of a commercially available cobalt / molybdenum catalyst. The evaluation consisted of a seven month test run on a laboratory hydrotreater using a diesel feed with 2000 ppm sulfur. The hydrotreating conditions were set to achieve a product sulfur level of about 10 ppm. The experiment was carried out at 642 F, 1400 scf / B, 600 psig, 1.0 hr−1, Co / Mo catalyst and diesel feed (sulfur level of ˜2000 ppm) as base case. At these conditions, product sulfur level was about 10 ppm at the beginning of the run. During the 7 month test, CO or CO2 was co-fed with H2 intermittently. The catal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com