Heat sink for LED bulbs

a technology of led bulbs and heat sinks, which is applied in the direction of heating apparatus, semiconductor devices for light sources, planar light sources, etc., can solve the problems of too high cost of lamps and manufacturing processes, and achieve the effects of low cost of manufacturing led lamps, less carbon emission, and rapid heat scattering

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

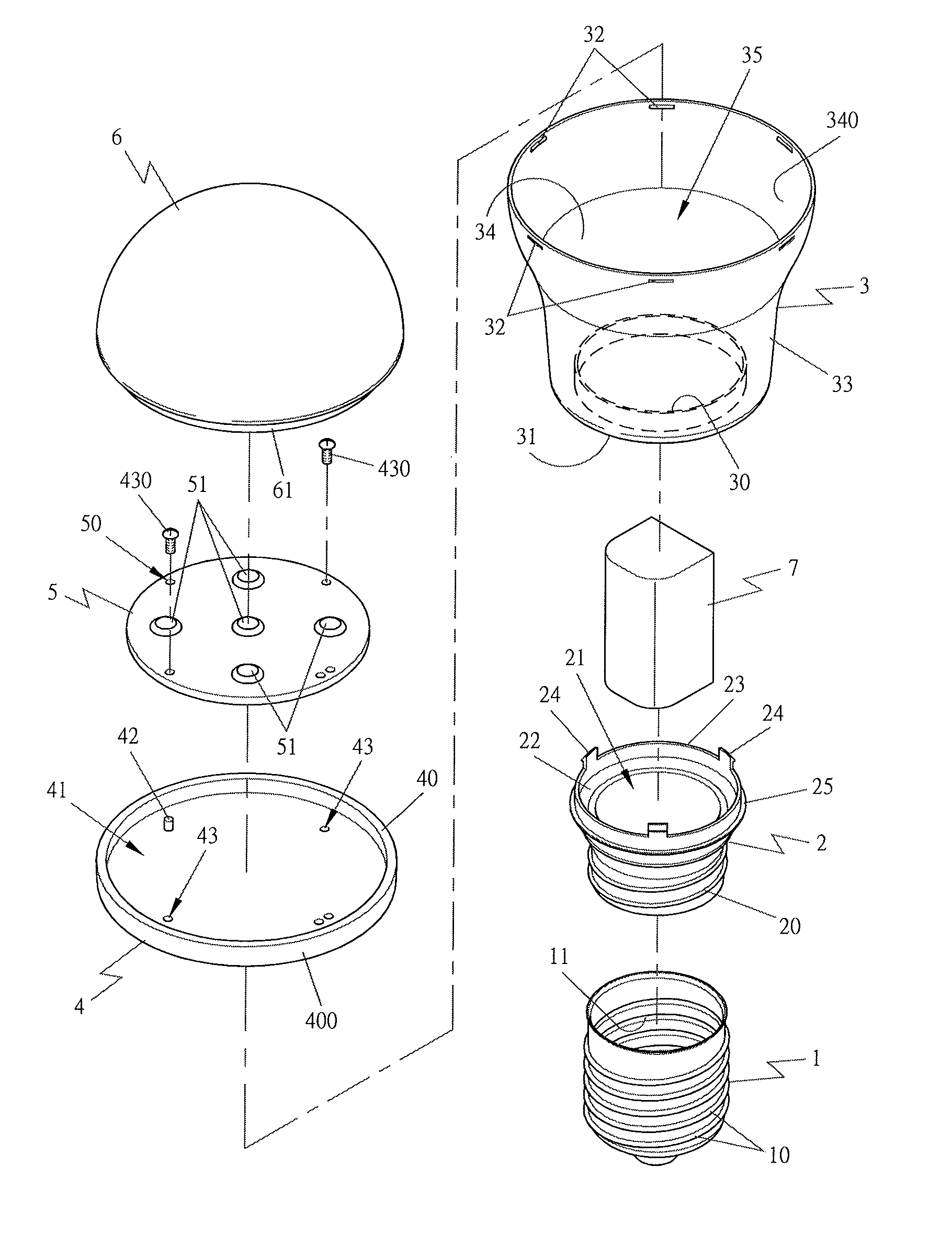

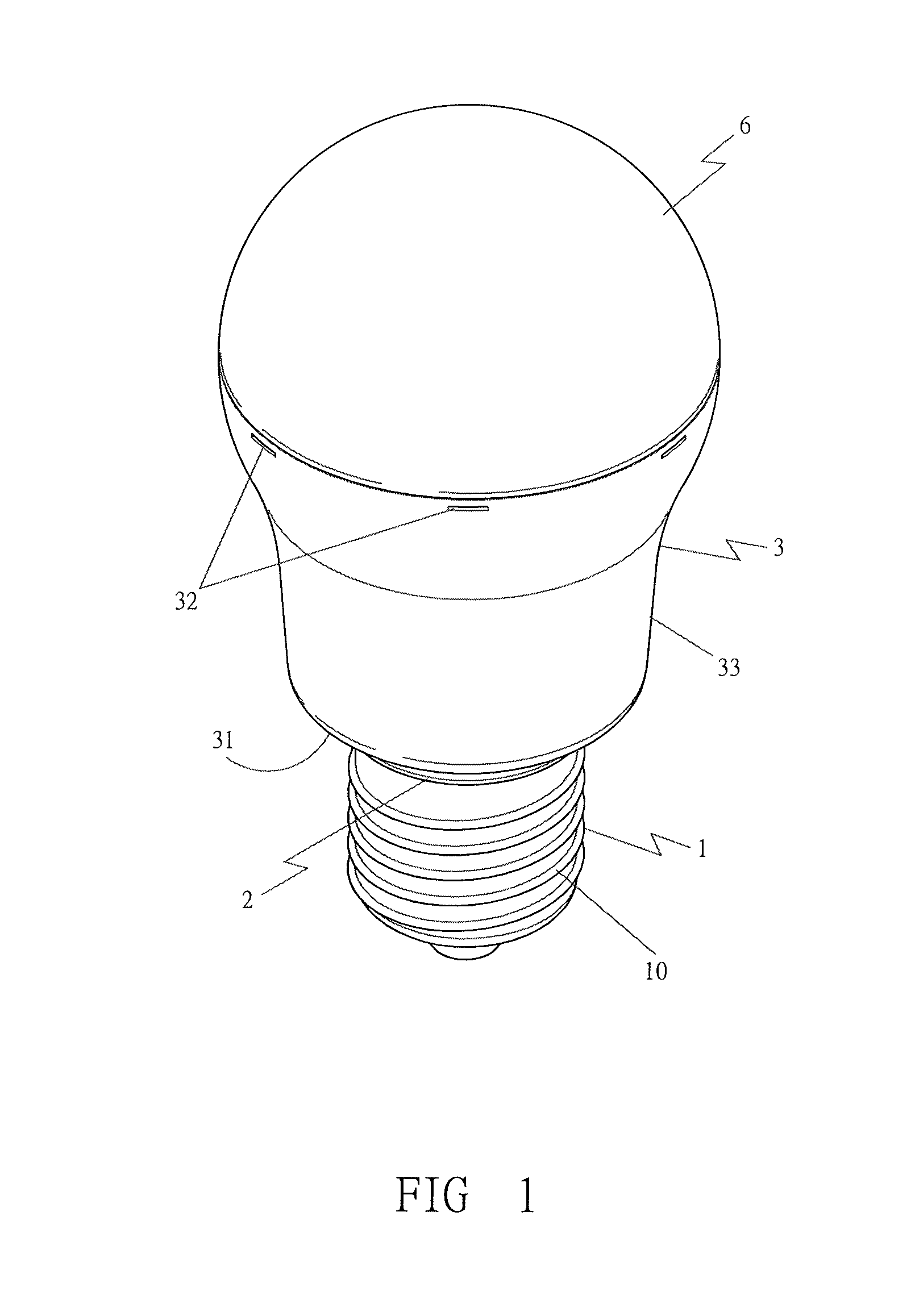

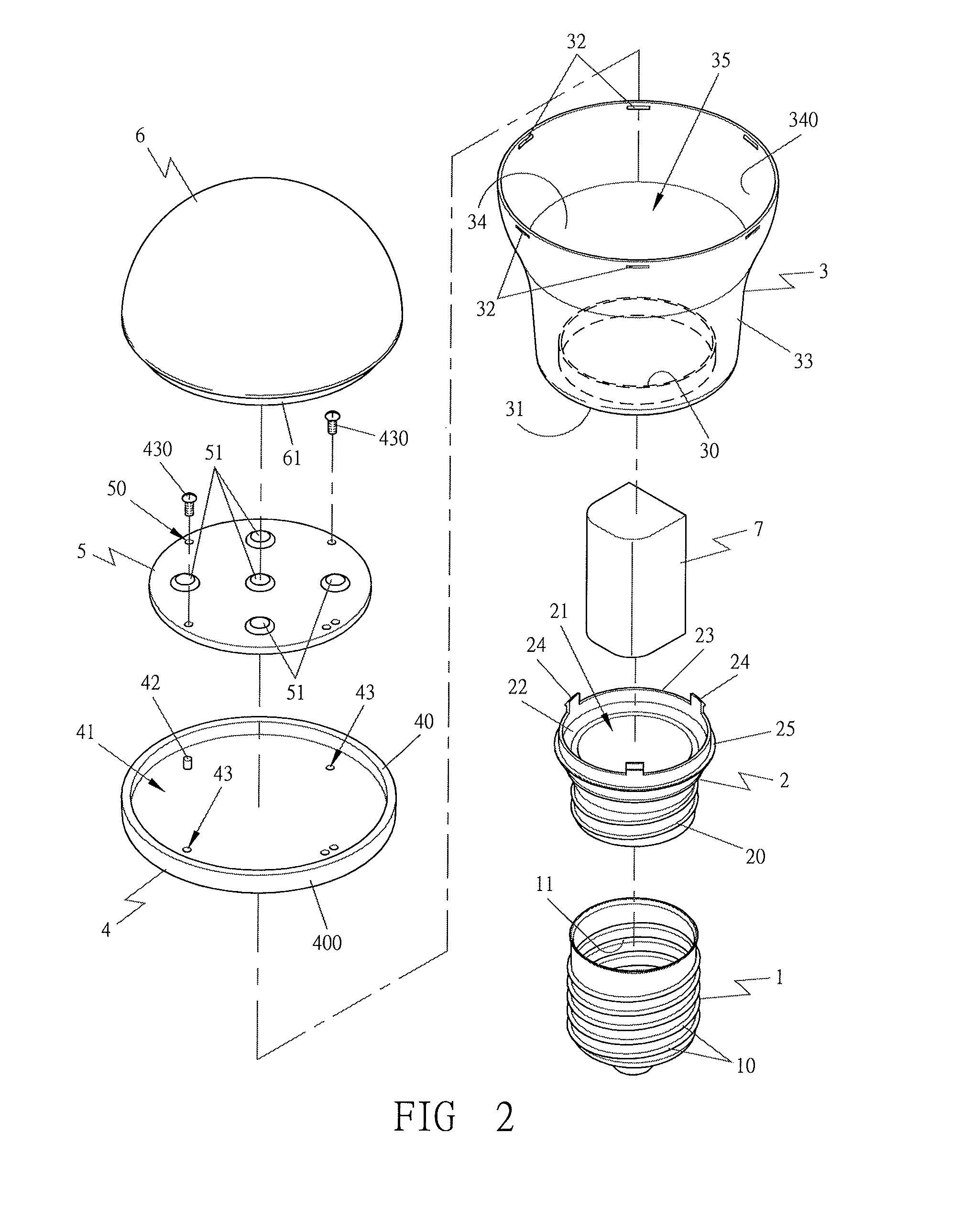

[0015]As shown in FIGS. 1-3, a preferred embodiment of a heat sink for LED bulbs in the present invention at least includes a base 1, a base connector 2, a lamp casing 3, a heat conducting plate 4, a circuit board 5 and a bulb hood 6.

[0016]The base 1 is provided with male threads 10 used to engage with a socket connected to a power, and female threads 11 to engage with the base connector 2.

[0017]The base connector 2 is provided with male threads 20 for engaging with the female threads 11 of the base 1, and a chamber 21 possessing an upper circumferential wall 22 combined with a chamber 35 of the lamp casing 3 to accommodate a power module. In addition, the base connector 2 is also provided with an extending circumferential wall 23, plural locking projections 24 built on the extending circumferential wall 23 to interlock with the lamp casing 3, and an outer circumferential wall 25.

[0018]The lamp casing 3 is formed like a trumpet, provided with an inner engaging circumferential wall 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com