Method of installing a hydroelectric turbine generator

a hydroelectric turbine and generator technology, applied in sea energy generation, tidal stream/damless hydropower, pipe laying and repair, etc., can solve the problems of inability to release the brake, the turbine cannot start spinning during installation,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045]An embodiment of the invention will now be described, by way of example only, with reference to the accompanying drawings, in which:

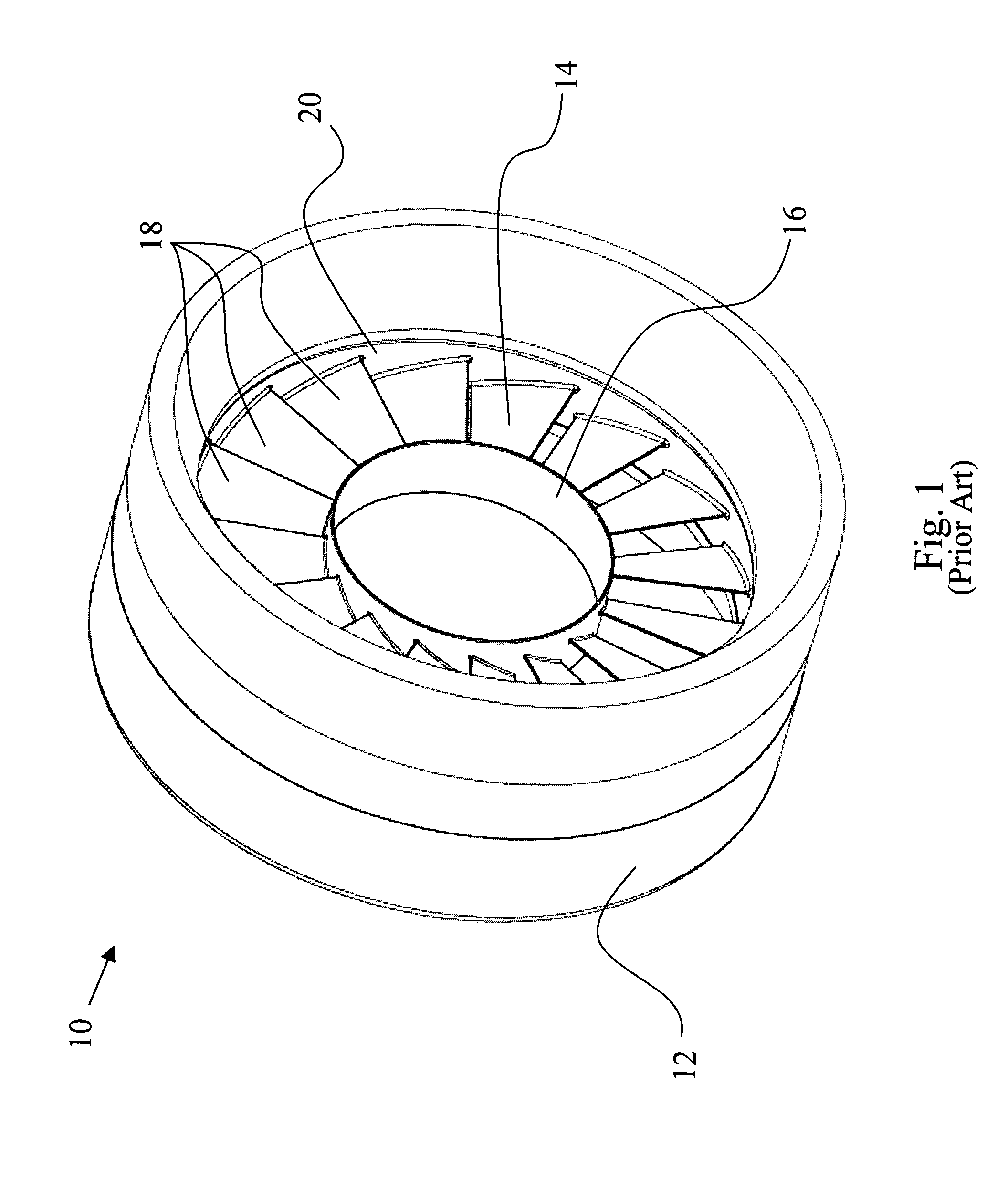

[0046]FIG. 1 is an isometric view of a prior art hydroelectric turbine generator;

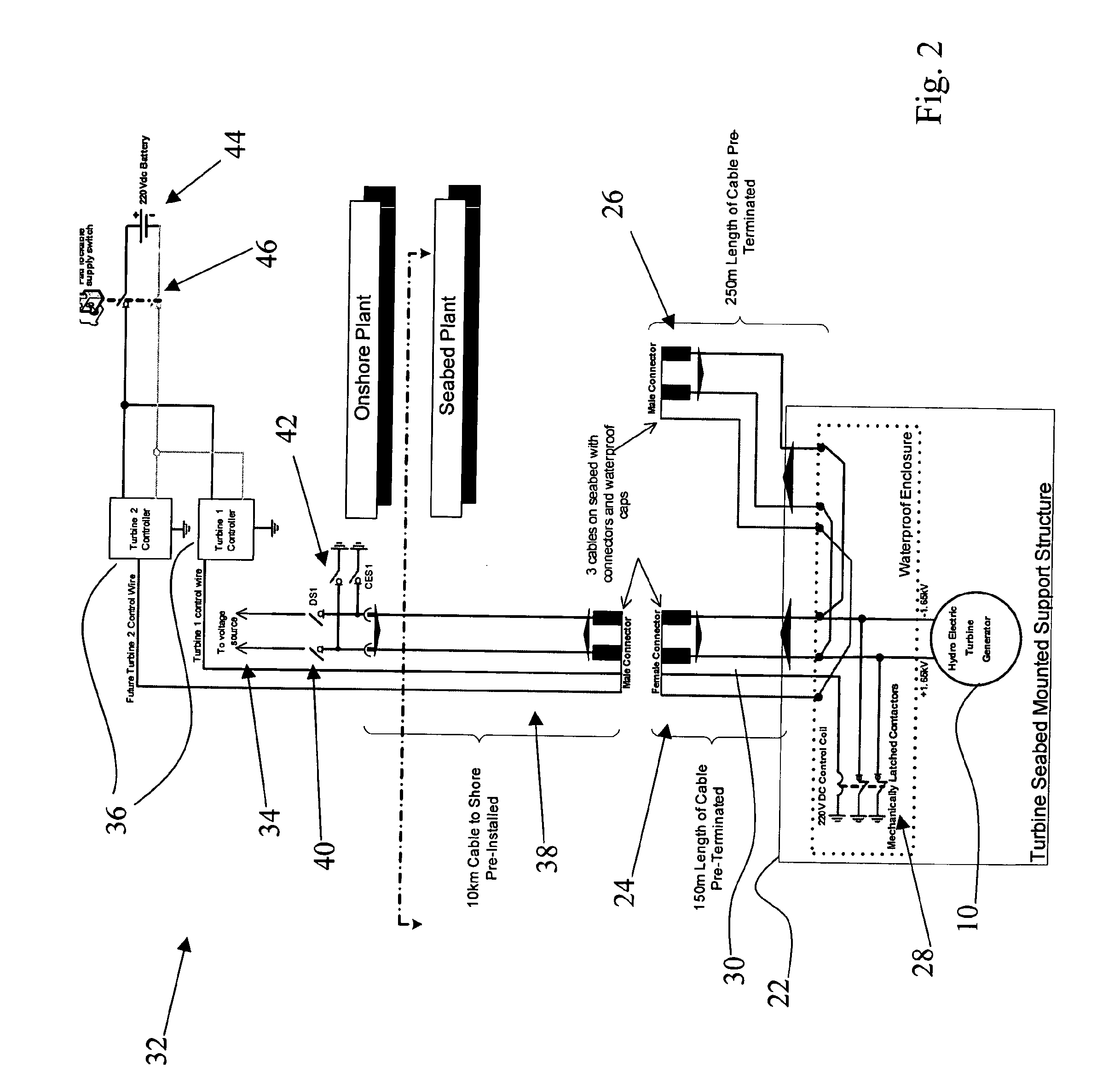

[0047]FIG. 2 is an outline of a sample configuration used for the installation and connection of a hydroelectric turbine generator to a supply grid;

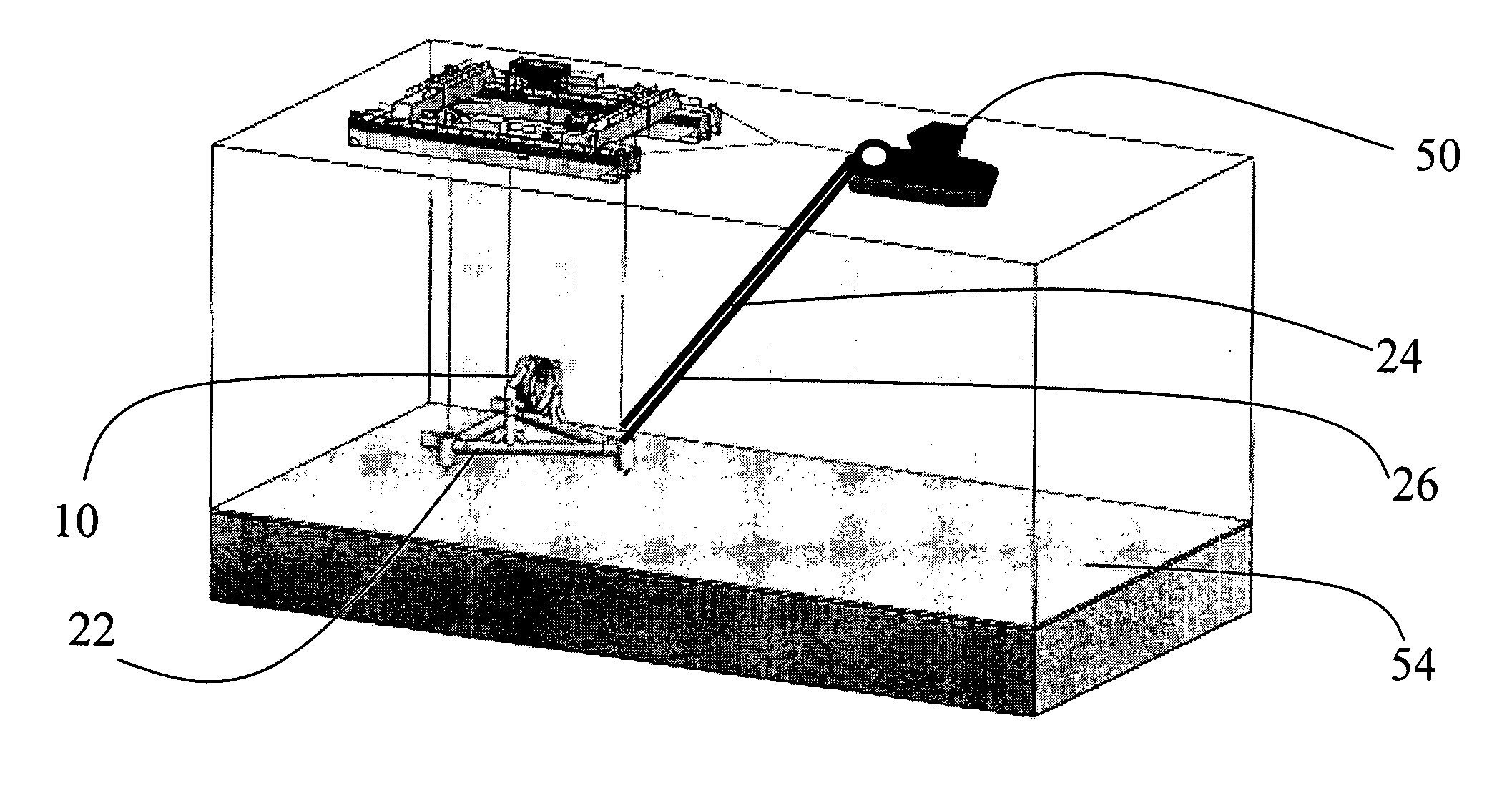

[0048]FIG. 3 is a view of an installation vessel and a hydroelectric turbine generator prior to deployment at an installation site; and

[0049]FIG. 4 is a view of an installation vessel and a hydroelectric turbine generator after deployment at an installation site.

[0050]With reference to FIG. 2, an overall view is presented of a sample circuit scheme for the installation of a hydroelectric turbine generator 10. The generator 10 is installed at an installation site in an area of tidal flow, the generator 10 being provided on a seabed mounted support structure 22. The generator 10 further comprises a generator cable 24, operab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com