Solar Powered Active Roof Ridge Vent

a solar energy and active technology, applied in ventilation systems, lighting and heating apparatus, heating types, etc., can solve the problems of insufficient aesthetics, difficulty in installation, and increase the energy cost of the home owner

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

embodiment

Preferred Embodiment

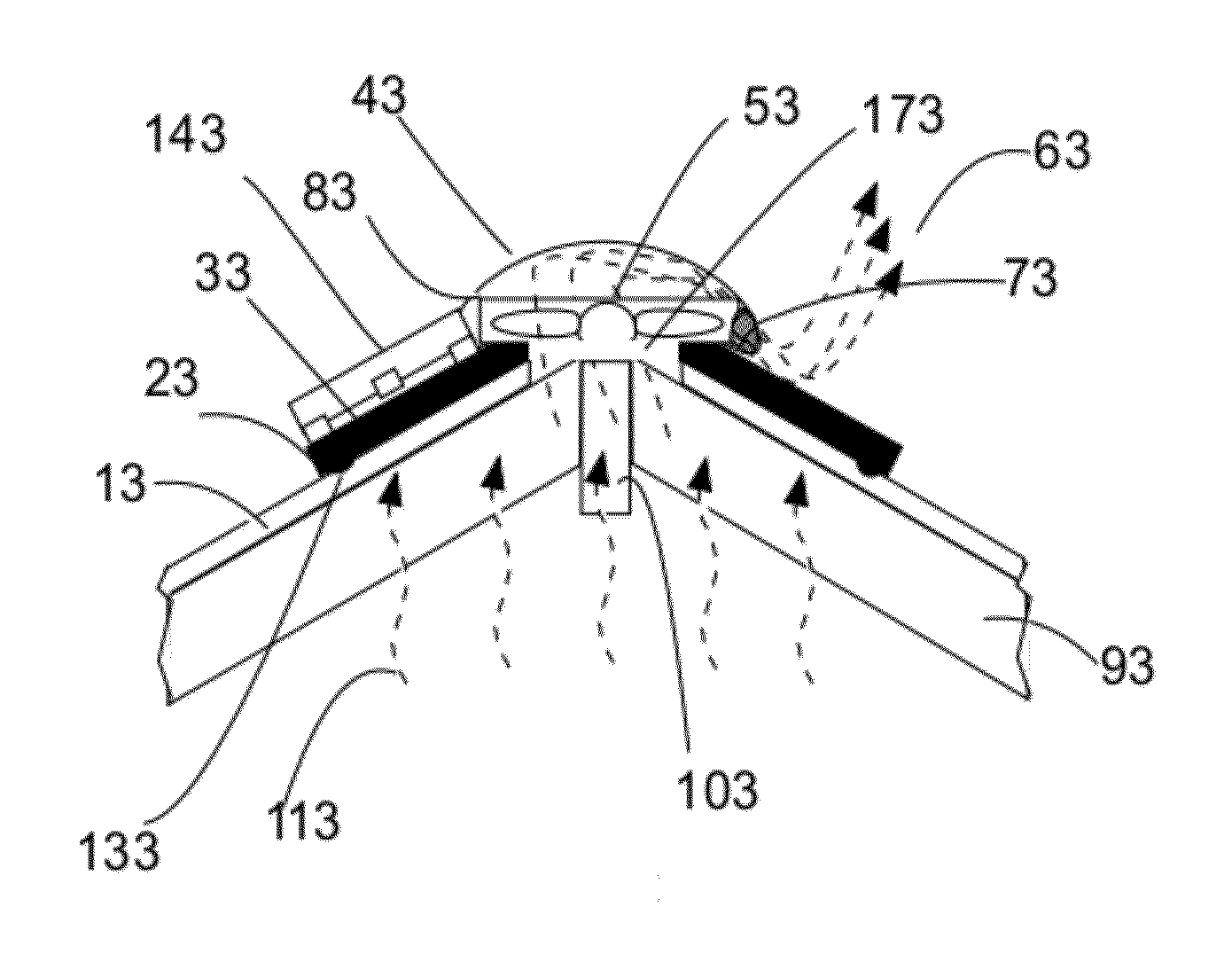

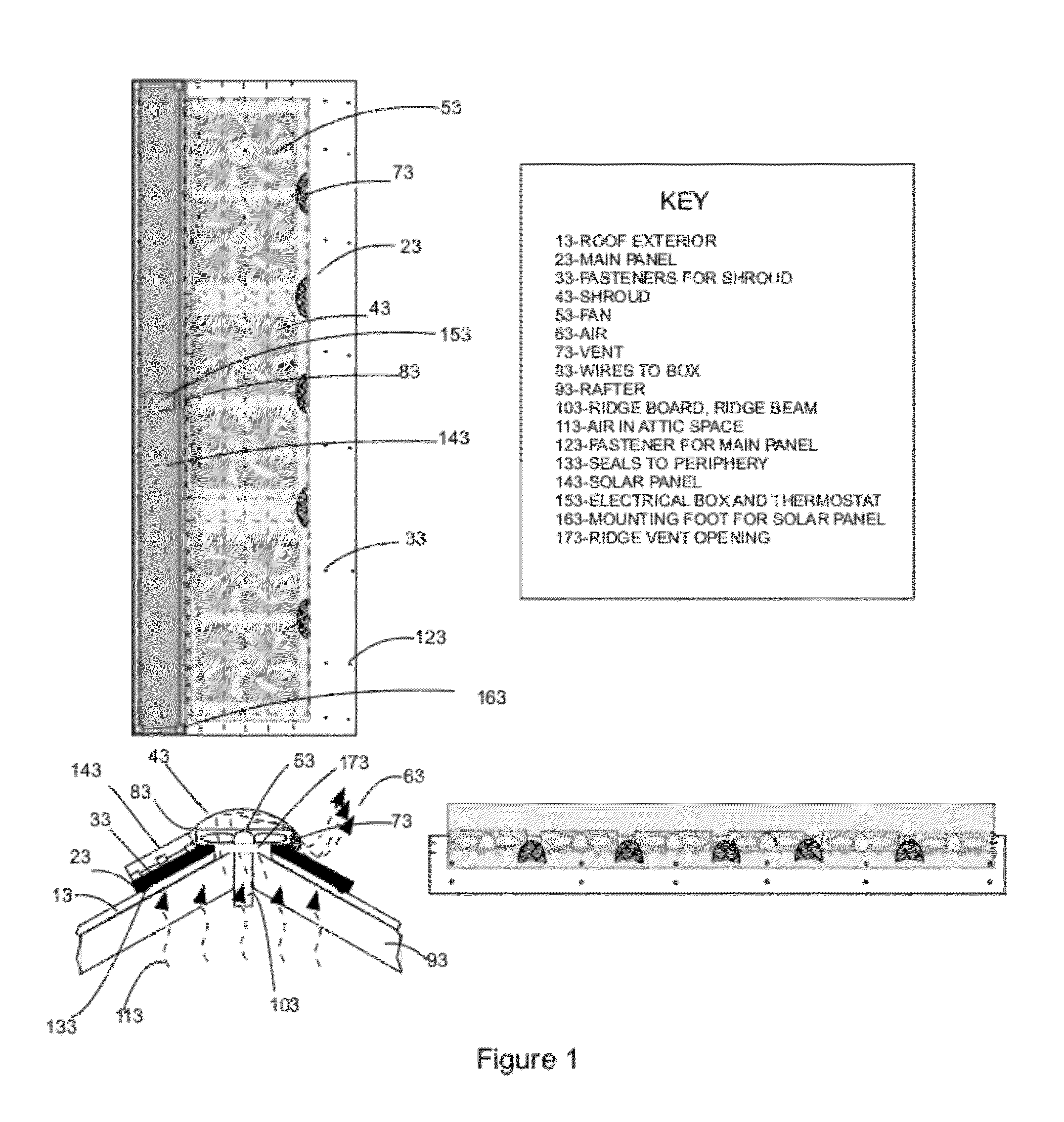

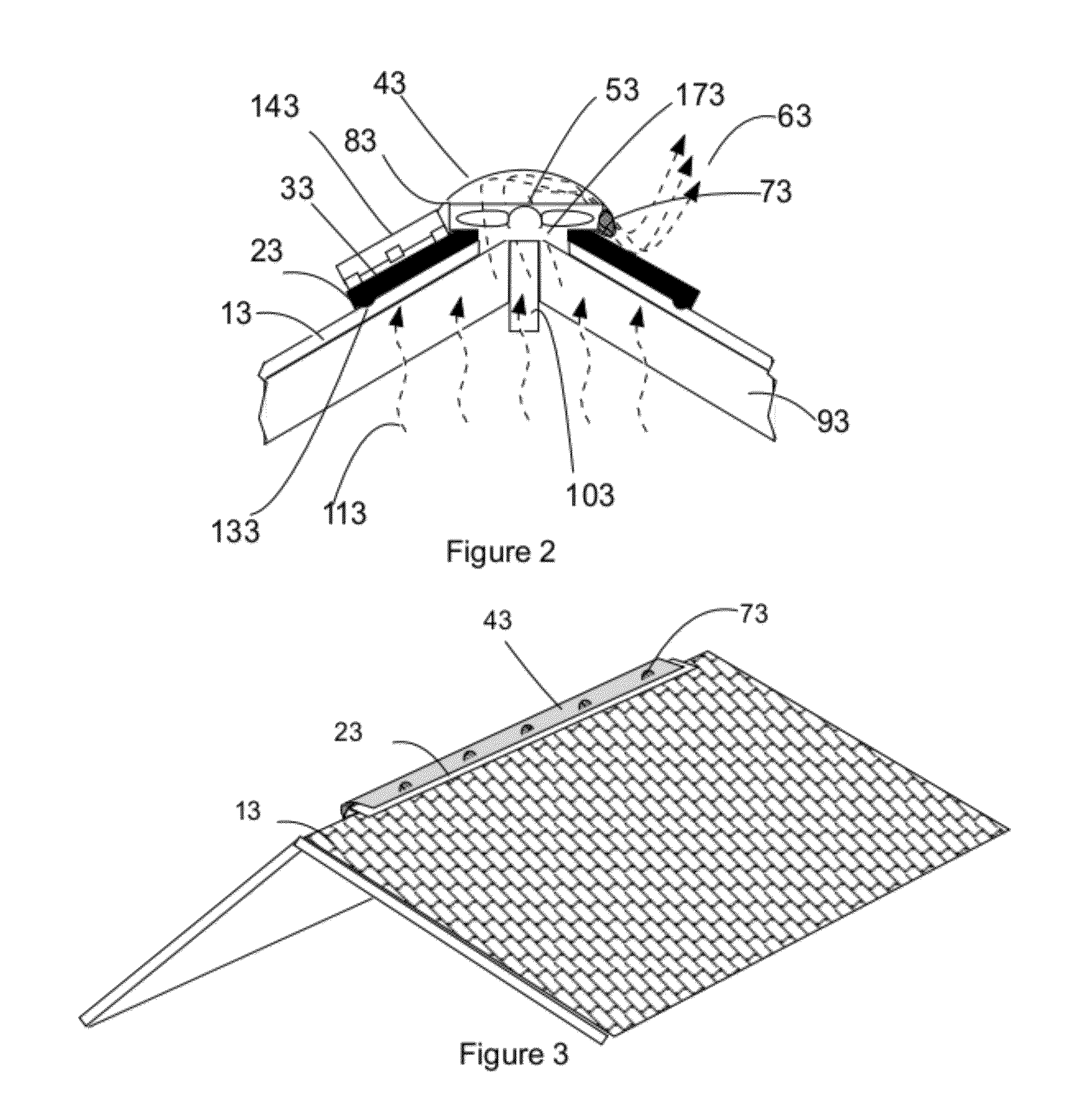

[0020]FIG. 1 shows the ventilation apparatus according to the preferred embodiment of the invention. As shown, the apparatus includes a rectangular panel, the main panel, (23) with a laterally flexible section allowing the panel to be installed over, to cover and seal the apex of a roof in which the upper section of the decking has been removed to allow air flow through the ridge. The laterally flexible panel is sealed along its edges using standard flexible sealing material to promote airflow through the active portion of the device (133). Holes are cut in to the laterally flexible panel's central section to allow for the installation of a series of axial fans (53) enabling them to extract air (113,63) from beneath the panel and exhaust it into the panels upper cavity formed by a flexible shroud (43). The fans are held in position on the main panel with standard fasteners. The flexible shroud (43) forms a cavity above the flexible main panel in which the hot exh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com