Centrifugal-chiller and method for controlling the same

a centrifugal and centrifugal technology, applied in the direction of refrigeration components, machines/engines, lighting and heating apparatus, etc., to achieve the effect of increasing efficiency, high efficiency and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039]An embodiment of the present invention will be described hereinbelow with reference to the drawings.

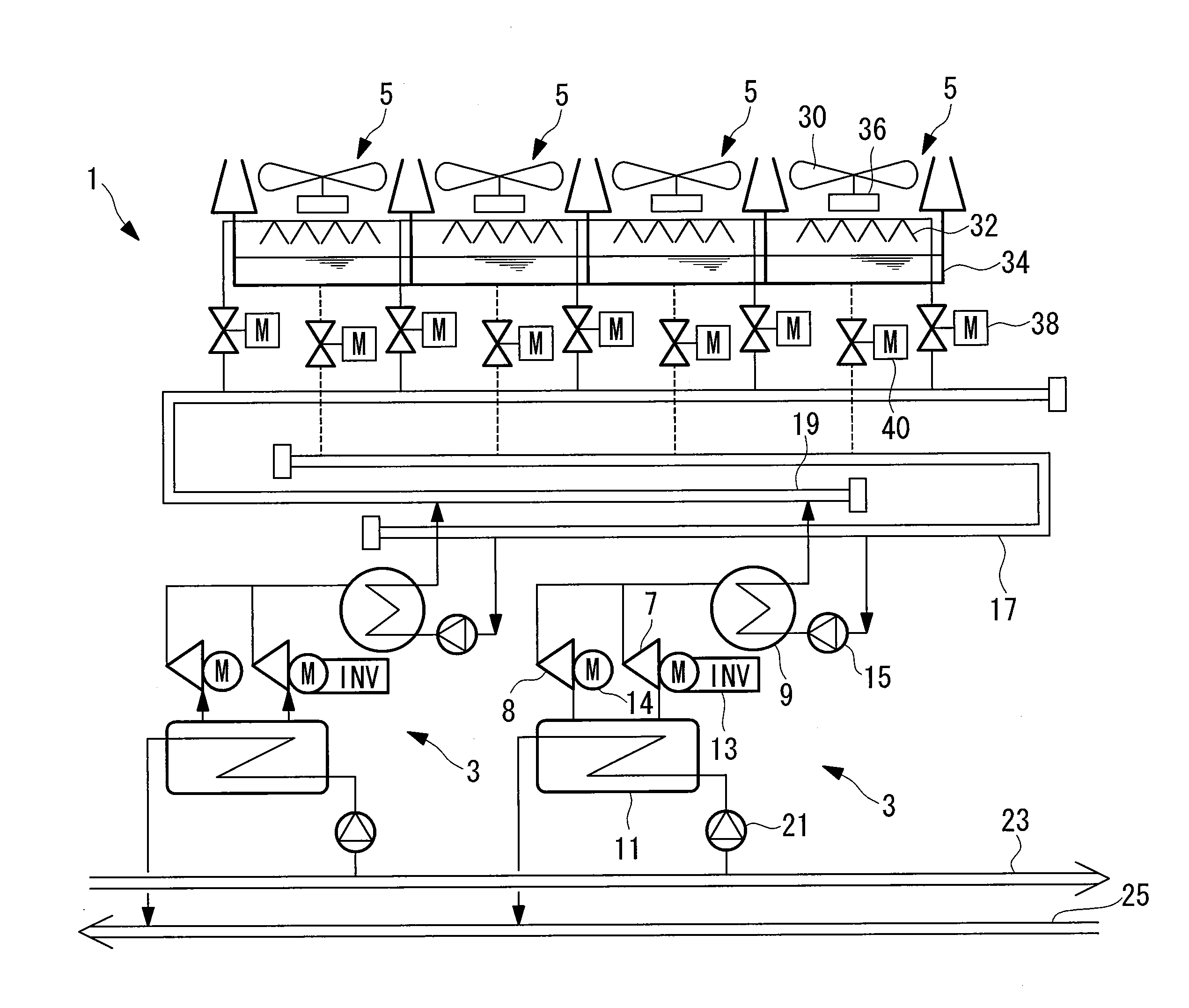

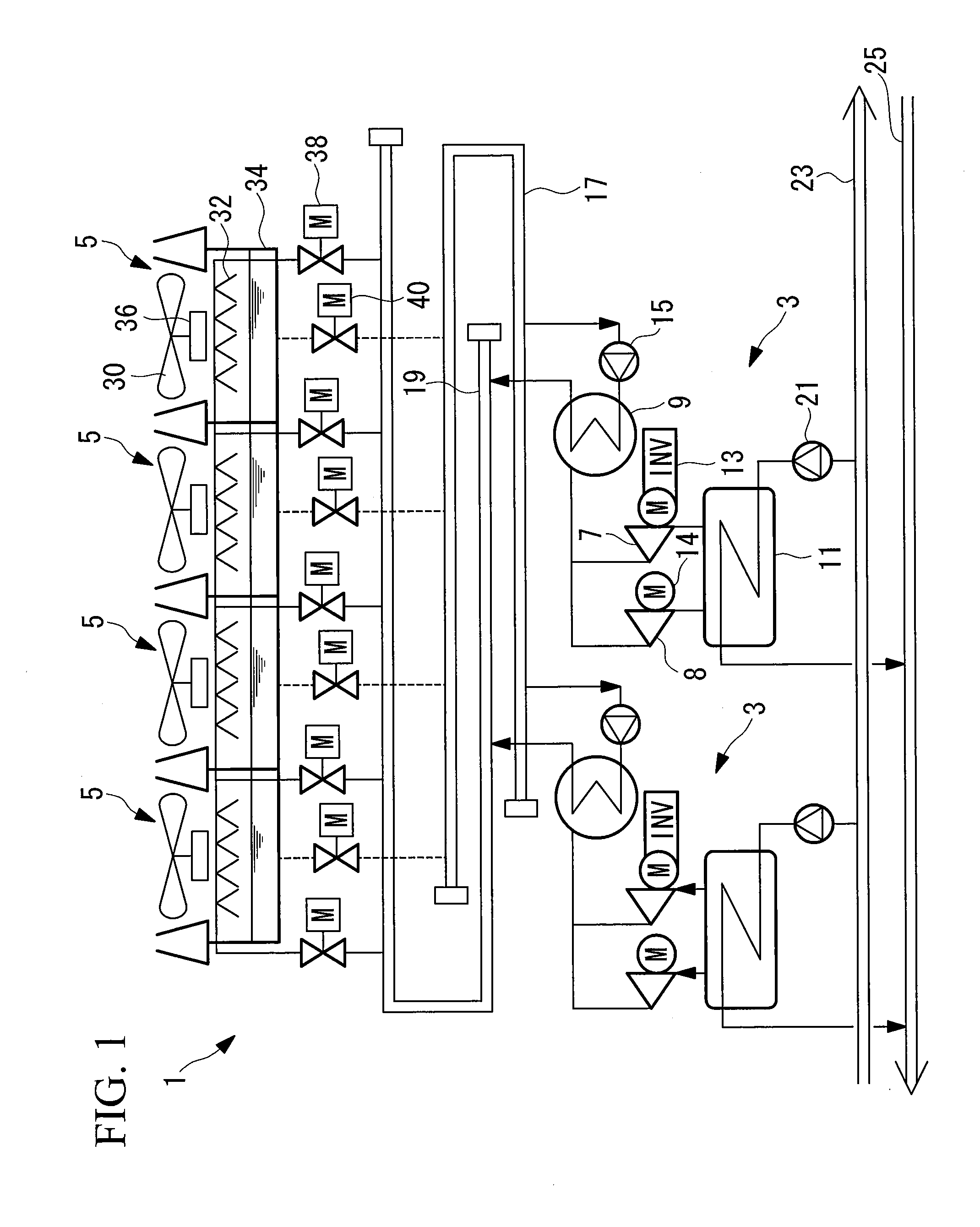

[0040]FIG. 1 shows an embodiment of a heat source system equipped with centrifugal-chillers according to the present invention. A heat source system 1 is equipped with a plurality of (two in this embodiment) centrifugal-chillers 3 provided in parallel and a plurality of (four in this embodiment) cooling towers 5 provided in parallel.

[0041]The centrifugal-chillers 3 are each equipped with two centrifugal-compressors 7 and 8 that compress a refrigerant, a condenser 9 that condenses the refrigerant compressed by the centrifugal-compressors 7 and 8 to liquefy it, an expansion valve (not shown) that expands the refrigerant condensed and liquefied by the condenser 9, and an evaporator 11 that evaporates the refrigerant expanded by the expansion valve.

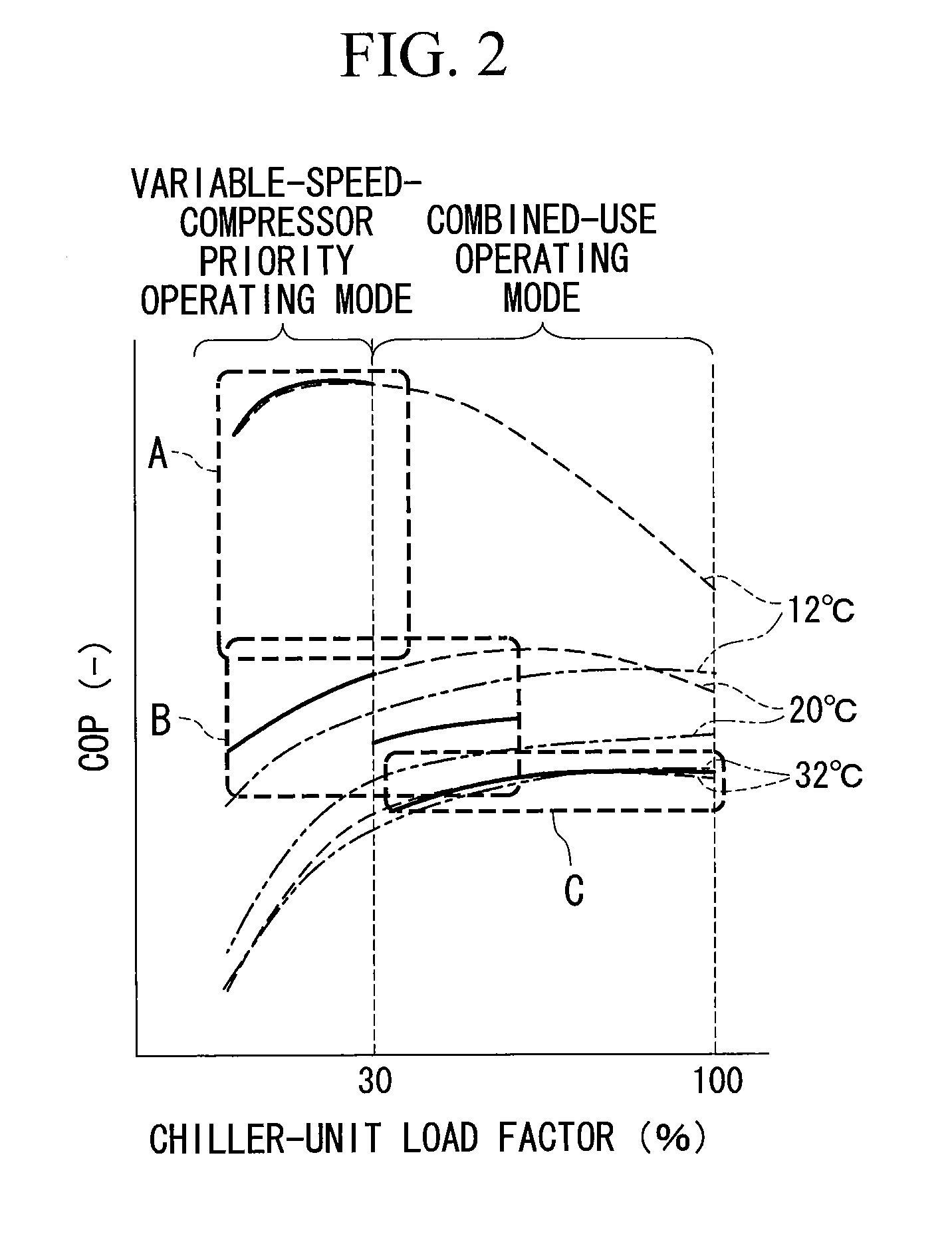

[0042]One centrifugal-compressor 7 of the two is driven by an electric motor 13 whose rotational frequency can be varied by an inverter....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com