Vehicle cooling system

a cooling system and vehicle technology, applied in the direction of machines/engines, electrochemical generators, battery/fuel cell control arrangements, etc., can solve the problems of high thermal load on the battery cells, damage to the cells, and the inability to cool using ambient air in all environmental conditions, so as to achieve maximum efficiency and minimum battery power loss, minimum electrical power consumption, and maximum efficiency of the overall system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

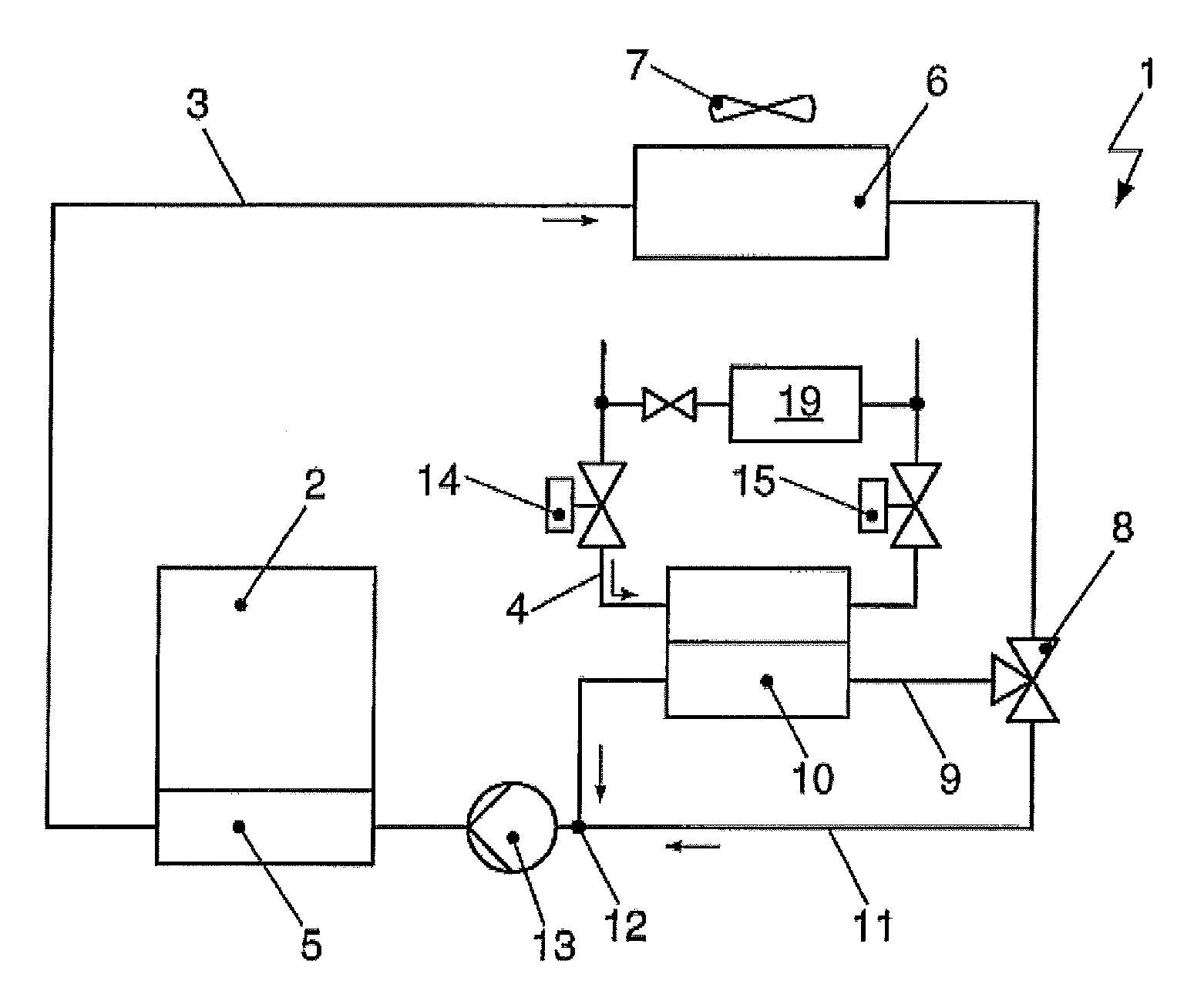

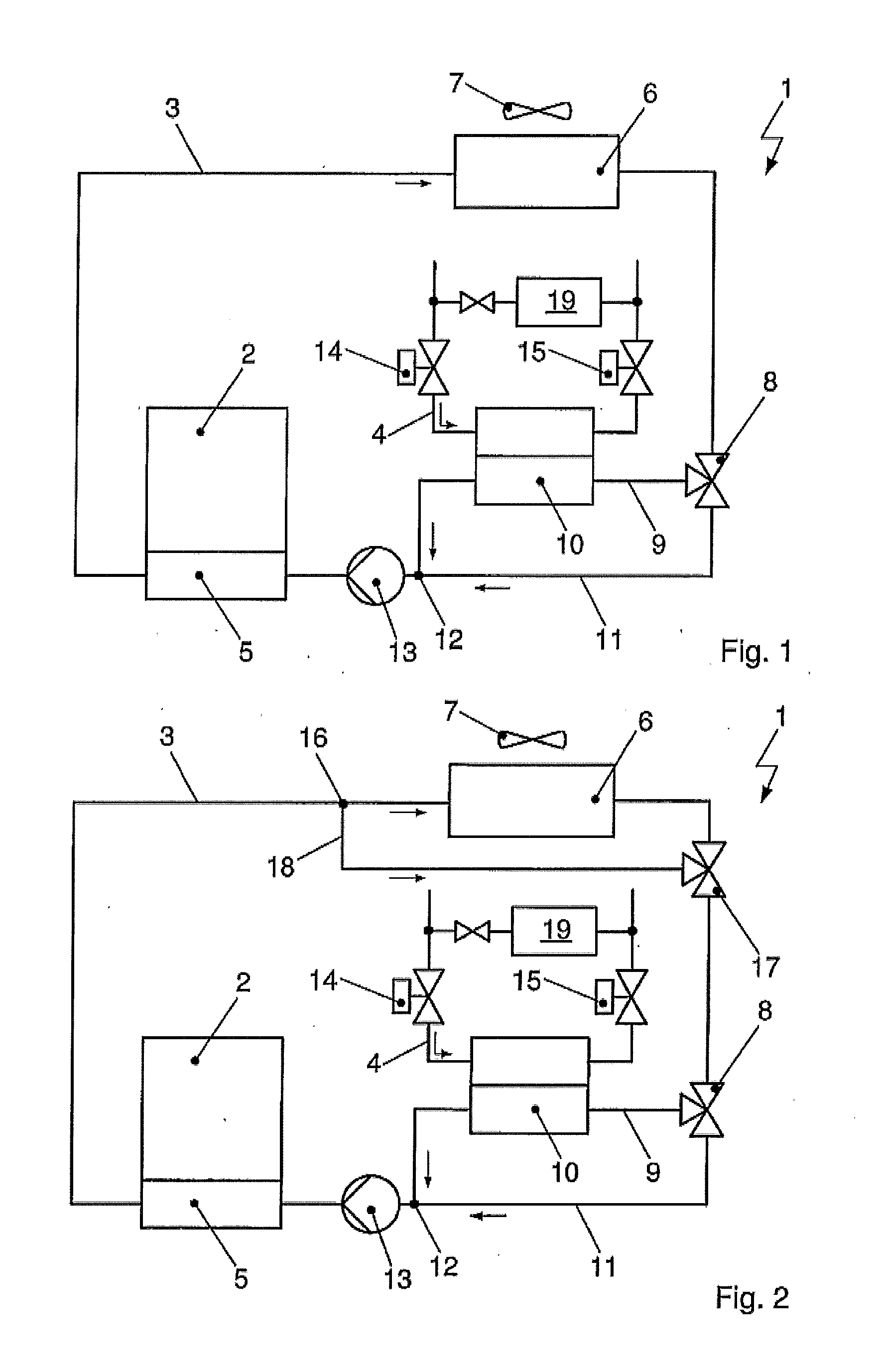

[0053]FIG. 1 shows a cooling system 1 comprising a coolant circuit 3, which is designed to cool and / or dissipate heat from a chemical energy storage device 2. In place of the energy storage device 2, which hereinafter is also referred to as a battery 2, it is also possible to thermally couple other components of the drive train of the vehicle, such as the engine of power electronics, to the cooling system 1.

[0054]The following detailed description and appended drawings describe and illustrate various embodiments of the invention. The description and drawings serve to enable one skilled in the art to make and use the invention, and are not intended to limit the scope of the invention in any manner.

[0055]The coolant circuit 3 has a pump device 13 for delivering the coolant. In the direction of flow of the coolant, a heat exchanger 5 is arranged downstream of the coolant pump, and is thermally coupled to the battery 2. Accordingly, several types of heat transfer are conceivable. The co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com