Power control system, power control method, power control device and power control program

a power control system and power control technology, applied in the direction of electrochemical generators, secondary cell servicing/maintenance, transportation and packaging, etc., can solve the problems of not systematically controlling the current based on the current used for charging the batteries, the inability to use the electric vehicle, and the likely thrown of the ampere breaker in the middle of the night, etc., to achieve the effect of efficient supply of power to an electric device and charging an electric vehicl

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

embodiment 1

Embodiment 1

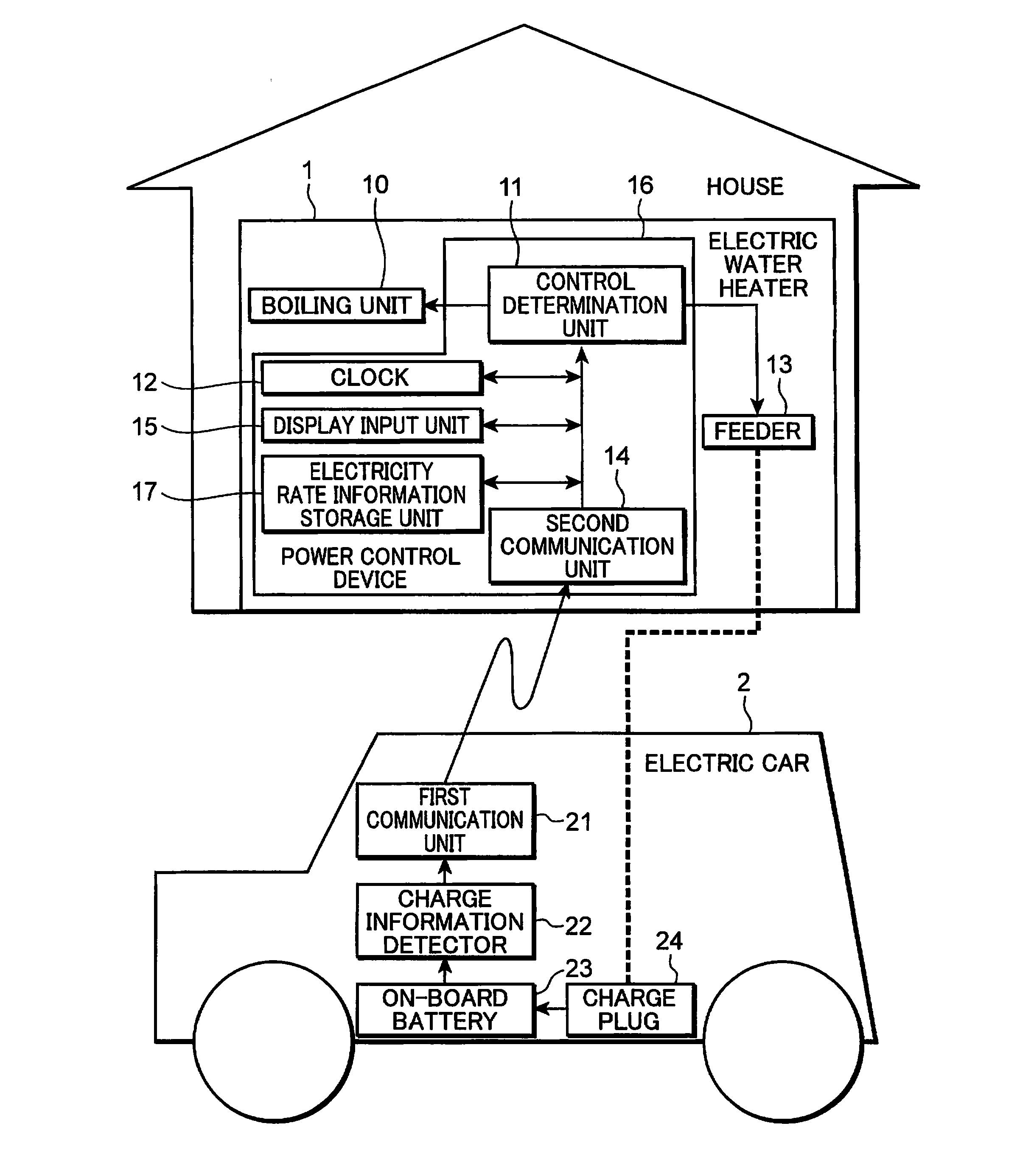

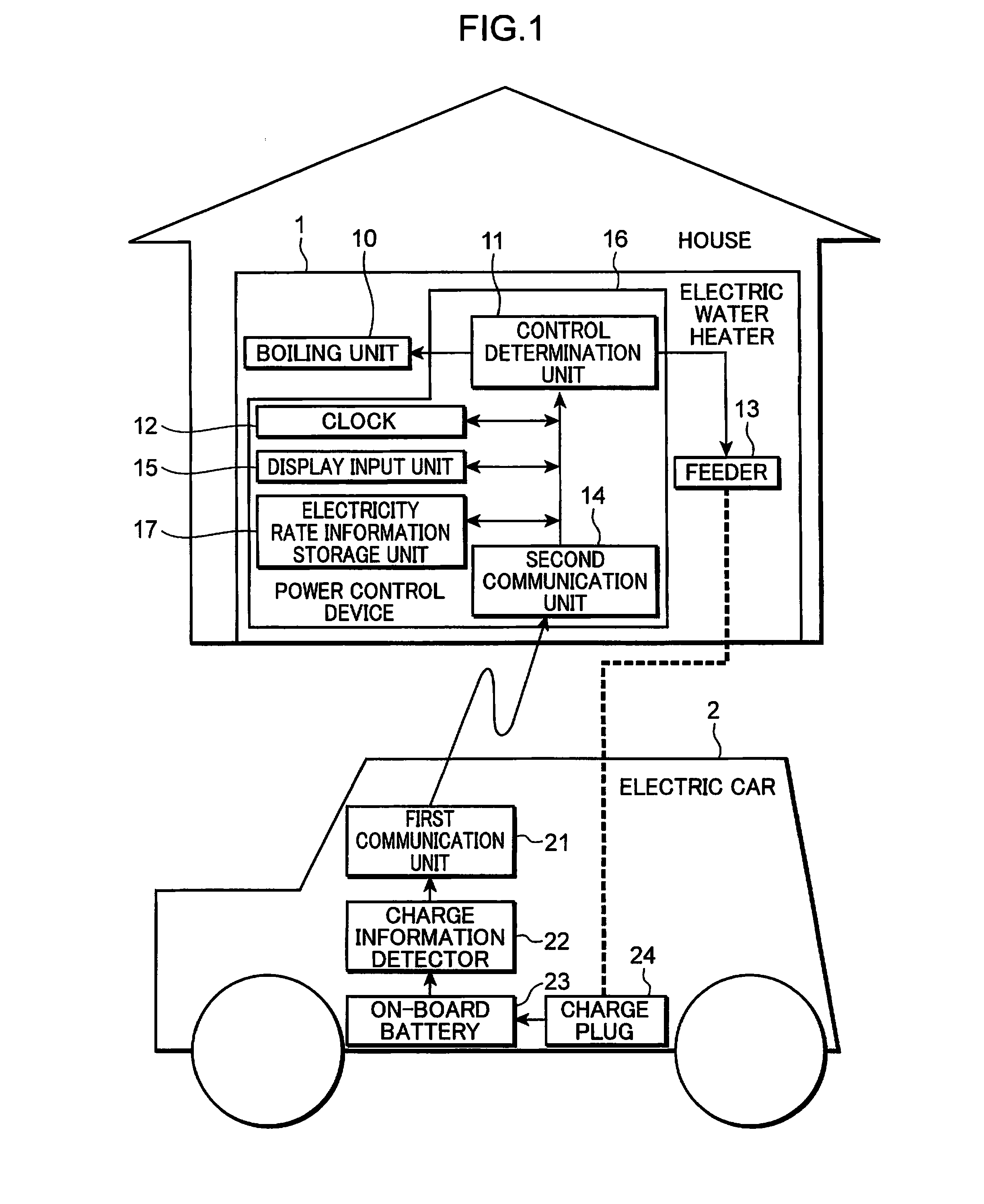

[0075]FIG. 1 is a diagram showing an example of a configuration of a power control system according to Embodiment 1 of the present invention. Embodiment 1 is described hereinafter with reference to FIG. 1.

[0076]The power control system shown in FIG. 1 has an electric water heater 1 and an electric car 2. The electric car 2 is an example of the electric vehicle, which is moved by receiving supply of power from a rechargeable battery equipped therein.

[0077]The electric car 2 is equipped with an on-board battery 23 for running a driving motor and an on-board electrical component, a charge plug 24, a charge information detector 22, and a first communication unit 21. The on-board battery 23 is charged by a feeder 13 (described later) via the charge plug 24. The charge information detector 22 acquires charge information pertaining to charging of a rechargeable battery. The charge information detector 22 detects charge information including a current remaining level of the on-...

embodiment 2

Embodiment 2

[0124]FIG. 7 is a diagram showing an example of a configuration of a power control system according to Embodiment 2 of the present invention. Embodiment 2 is described hereinafter with reference to FIG. 7.

[0125]The power control system shown in FIG. 7 has the electric water heater 1 and the electric car 2. The descriptions of the configurations according to Embodiment 2 that are the same as those of Embodiment 1 are omitted.

[0126]The electric car 2 is equipped with the on-board battery 23 for running a driving motor and an on-board electrical component, the charge plug 24, the charge information detector 22, the first communication unit 21, and an on-board navigation device 25. The on-board battery 23 is charged by the feeder 13 (described later) via the charge plug 24. The on-board navigation device 25 acquires information on a current position of the electric car 2 and provides information pertaining to a distance between the current position and the house. Note that ...

embodiment 3

Embodiment 3

[0169]The electric car 2 according to Embodiment 2 computes the remaining level of the on-board battery 23 that is obtained at the time of arrival of the electric car 2 at the installation location where the power control device 16 (the electric water heater 1) is installed. In Embodiment 3, on the other hand, a server device computes the remaining level of the on-board battery 23 that is obtained at the time of arrival of the electric car 2 at the installation location where the power control device 16 (the electric water heater 1) is installed.

[0170]FIG. 8 is a diagram showing an example of a configuration of a power control system according to Embodiment 3 of the present invention. Embodiment 3 is described with reference to FIG. 8.

[0171]The power control system shown in FIG. 8 has the electric water heater 1, the electric car 2, and a server device 3. The descriptions of the configurations according to Embodiment 3 that are the same as those of Embodiment 2 are omit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com