Motor driven cabin air compressor with variable diffuser

a cabin air compressor and variable technology, applied in the direction of machines/engines, reaction engines, liquid fuel engines, etc., can solve the problem that the operation of dual air conditioning packs may not be necessary or efficien

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

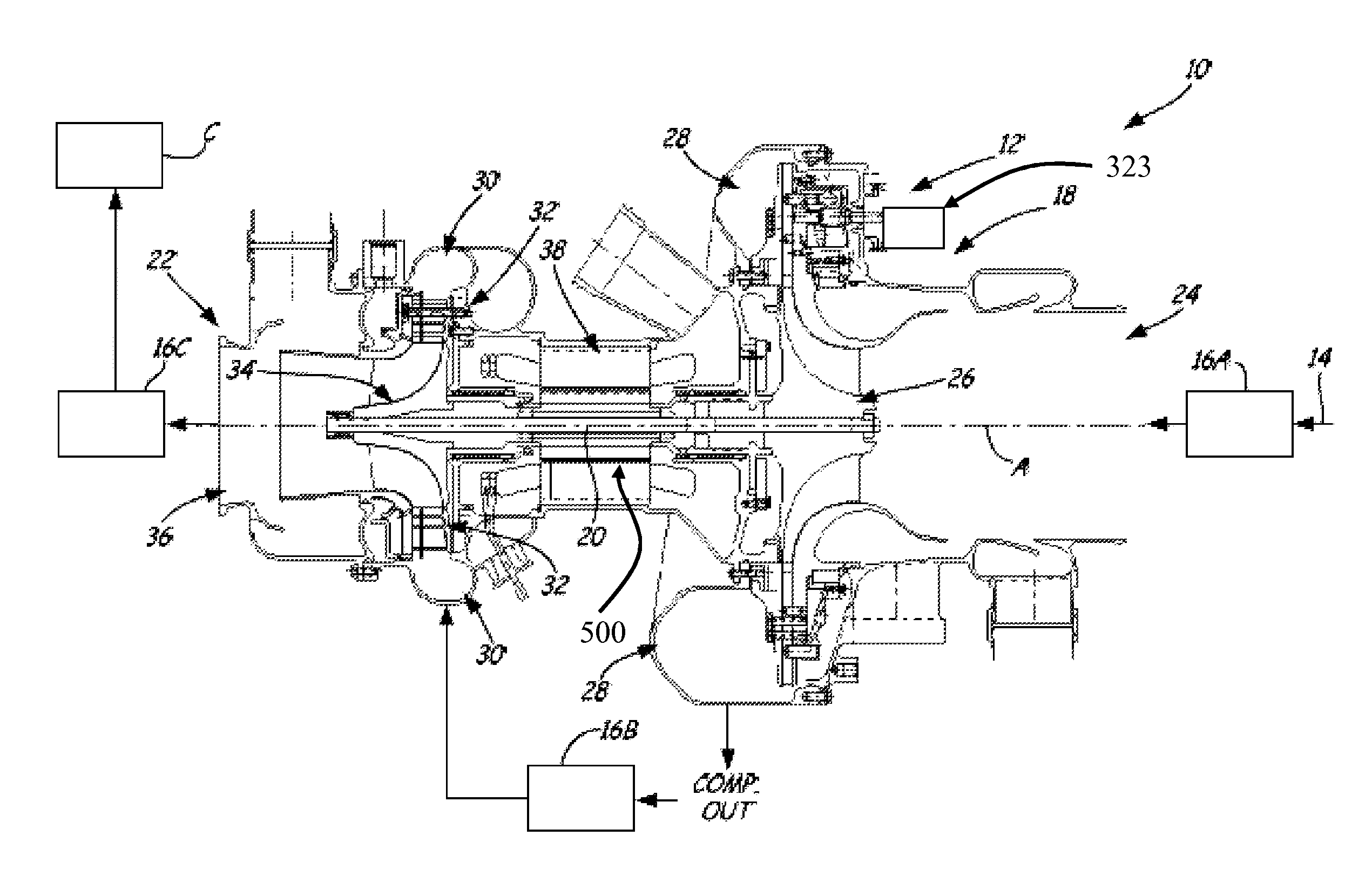

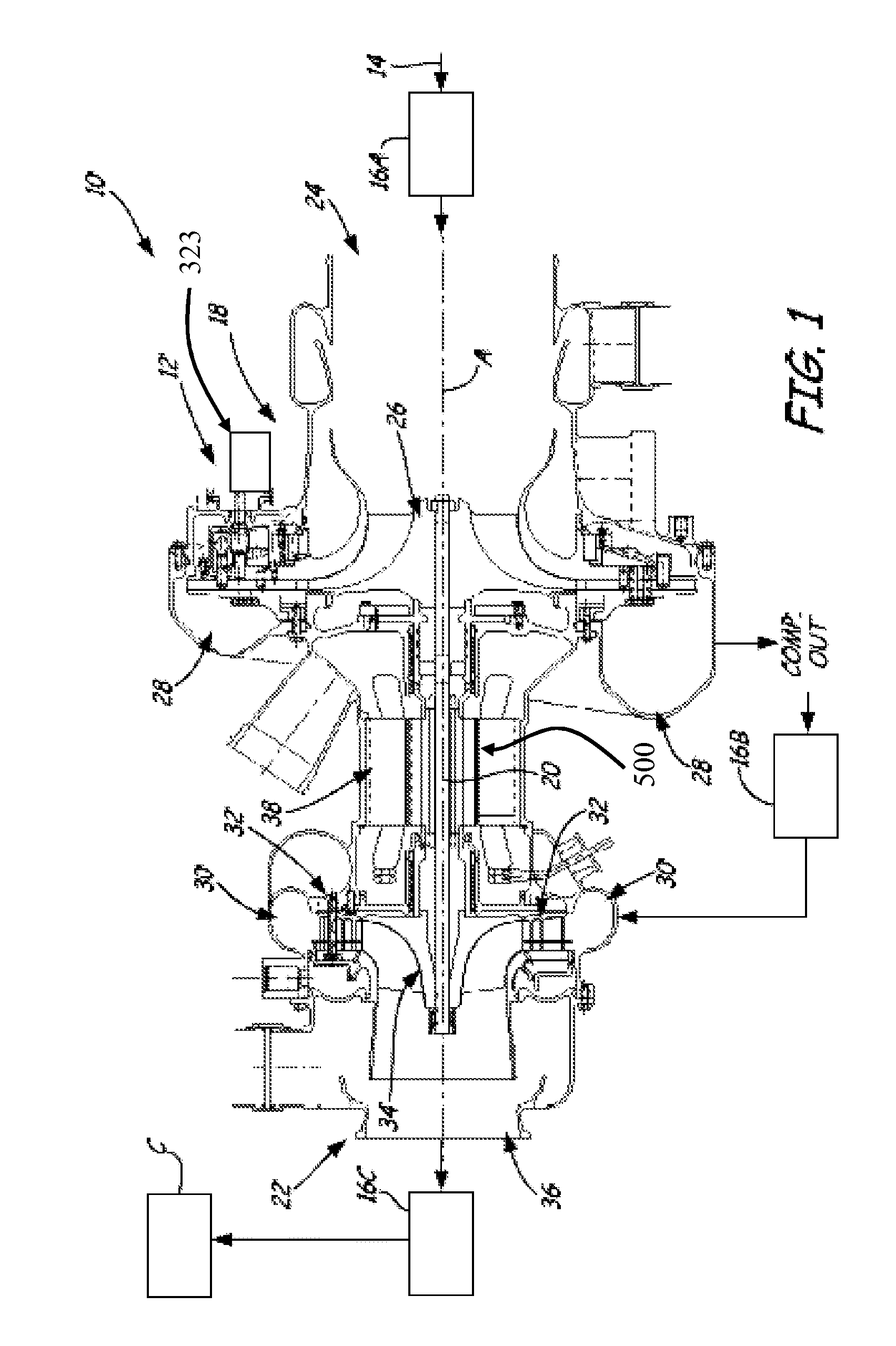

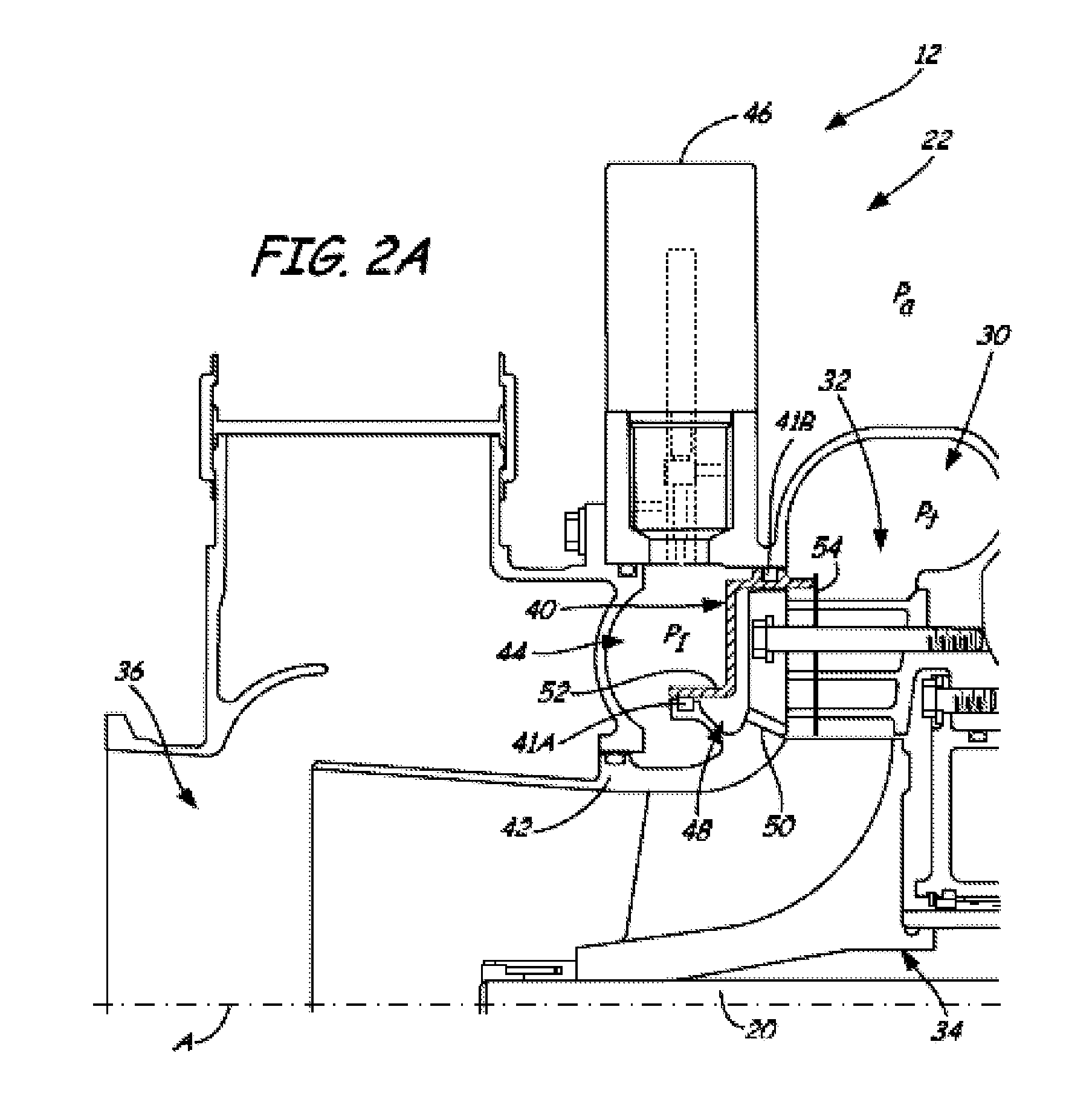

[0016]FIG. 1 shows a schematic view of an environmental control system (ECS) 10. The environmental control system 10 includes an air cycle machine 12 that receives air 14 that is conditioned by various devices symbolically indicated as 16A, 16B, and 16C to produce air flow at a desired temperature and pressure for aircraft cabin C. The air cycle machine 12 includes a compressor section 18, a shaft 20, and a turbine section 22. The compressor section 18 has a compressor inlet 24, a compressor wheel 26 and a compressor outlet 28. The turbine section 22 includes a turbine inlet 30, turbine inlet nozzle 32, turbine wheel 34 and turbine outlet 36.

[0017]System air 14 is bled from one or more of the compressor stages of the gas turbine engines of the aircraft or directed from an air source at another location on the aircraft. One or more devices 16A can condition (e.g., preheat, acoustically treat) the air 14 prior to its entry into the air cycle machine 12. The air 14 enters the air cycle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com