Thermal Impedance Matching Using Common Materials

a technology of impedance matching and common materials, applied in the field of heat management systems, can solve the problems of increasing system size, weight/material/cost, high process inefficiency, etc., and achieve the effect of minimizing temperature change and dissipating hea

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example

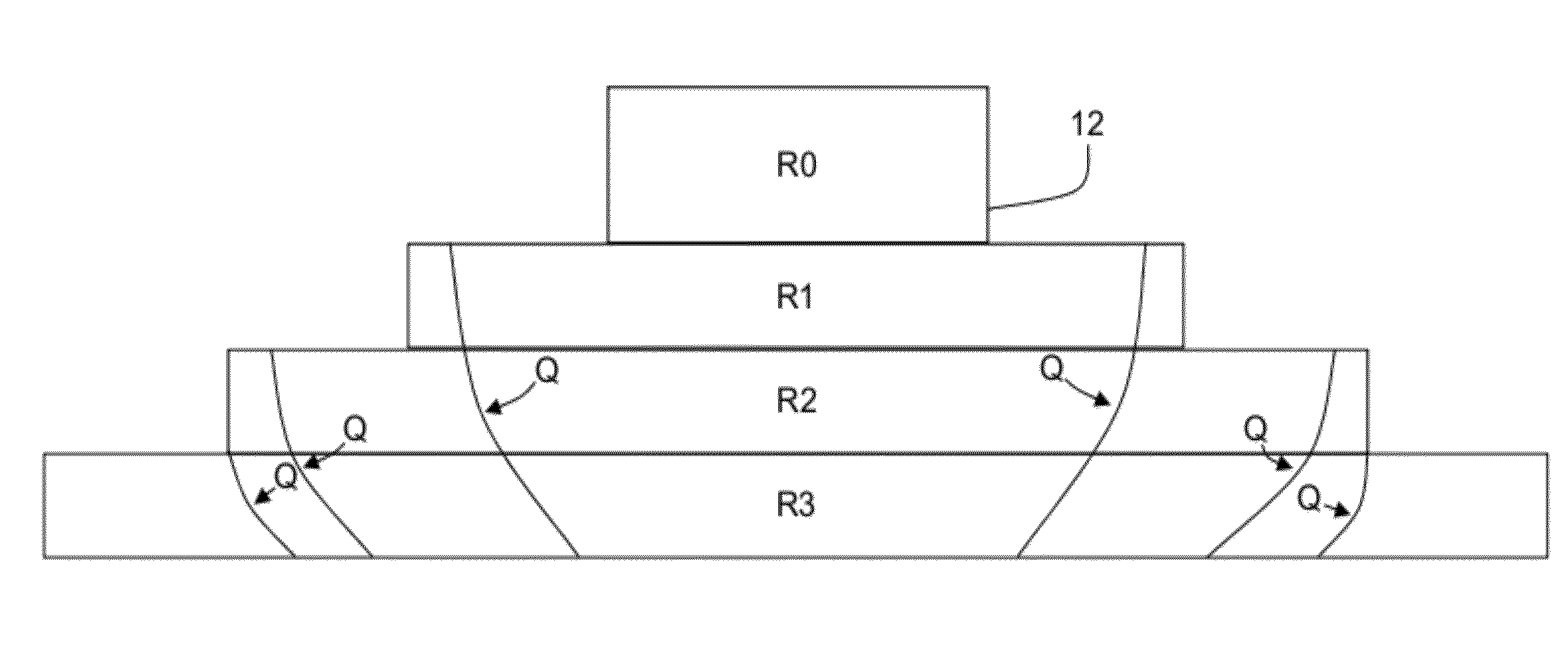

[0135]FIGS. 31-36 show an embodiment of the present invention incorporating a variable-gradient layer. In this embodiment, a system 700 has a 30 Watt LED 702 where s first layer 704 of a copper, a second layer 710 of aluminum, a third layer 712 of a stainless steel, and a fourth layer 714 of variable-gradient material.

[0136]The fourth layer 714 has a distributed thermal impedance, such that a thermal impedance gradient is established within the fourth layer 714. In this embodiment, the fourth layer 714 has a low thermal impedance at an interface between the third layer 712 and the fourth layer 714 relative to the thermal impedance of the third layer 712 to a much lower thermal impedance relative to the third layer 712 at an interface between the fourth layer 414 an ambient layer, typically air or insulation.

[0137]In this embodiment, the fourth layer 714 was formed by suspending stainless steel wool 720 from the third layer 712. The steel wool 720 was then impregnated with a lower th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com