Electrostatic atomization device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

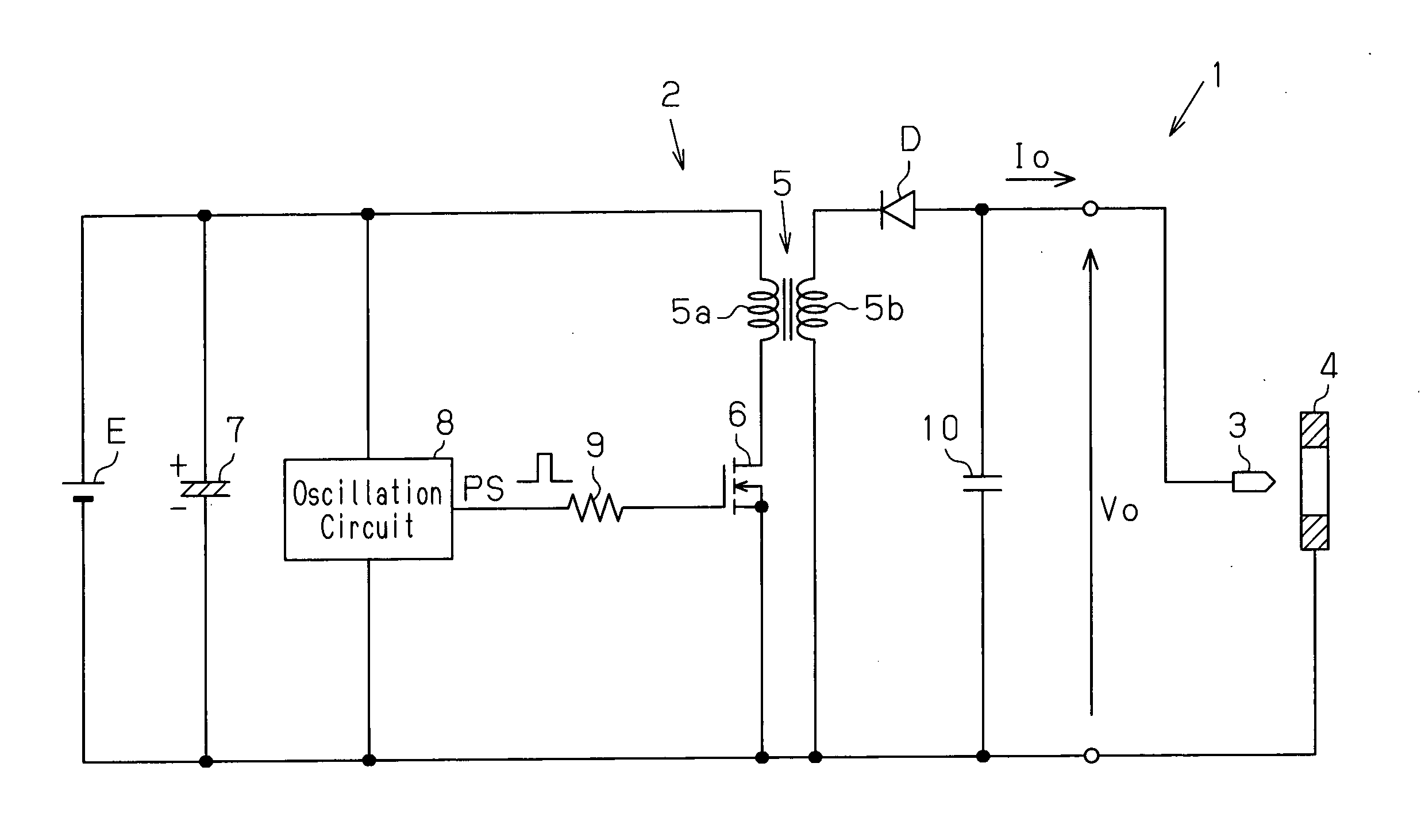

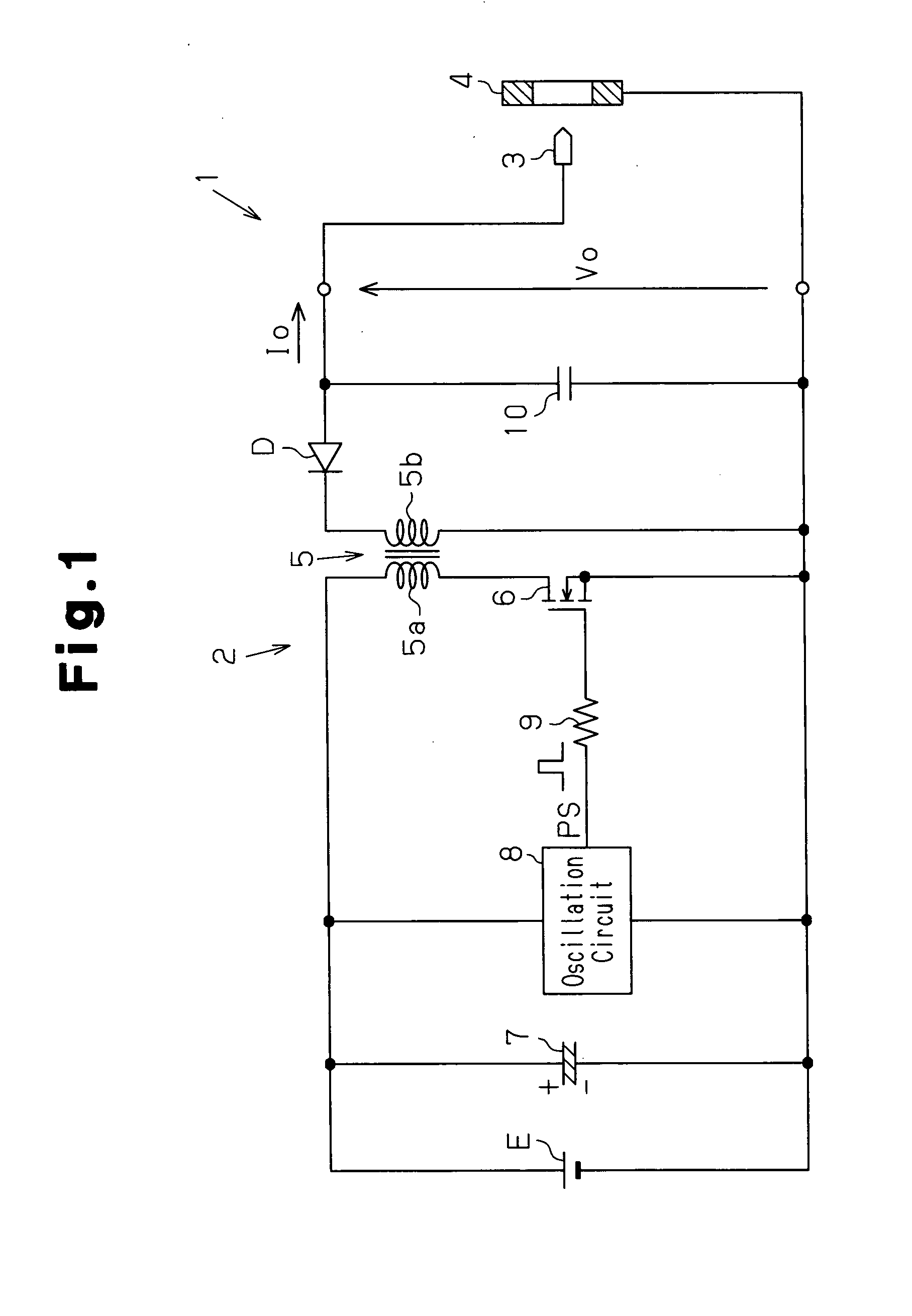

[0015]An electrostatic atomization device 1 according to one embodiment of the present invention will now be discussed with reference to the drawings.

[0016]FIG. 1 shows a high voltage generation circuit 2 of the electrostatic atomization device 1. The high voltage generation circuit 2 applies high voltage between a discharge electrode 3 and ground, namely, a ground electrode 4, which form a discharge unit arranged in the electrostatic atomization device 1. The discharge electrode 3 and the ground electrode 4 are spaced apart from each other by a predetermined distance. In a state in which water, serving as liquid, is supplied to the distal end of the discharge electrode 3, the high voltage generation circuit 2 applies high voltage between the discharge electrode 3 and the ground electrode 4.

[0017]As a result, Coulomb force locally raises the liquid surface of the water supplied to the distal portion of the discharge electrode 3 into a conical form (Taylor cone). The raised conical f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com