Device for pre-tensioning a machine frame, machine frame, and pressing and drawing device

a technology for pretensioning and machine frames, which is applied in the direction of presses, manufacturing tools, forging presses, etc., can solve the problems of difficult installation of such machine frames, large weight large dimensions of such steel columns, so as to achieve easy installation and maintenance, and the effect of reducing the number of components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

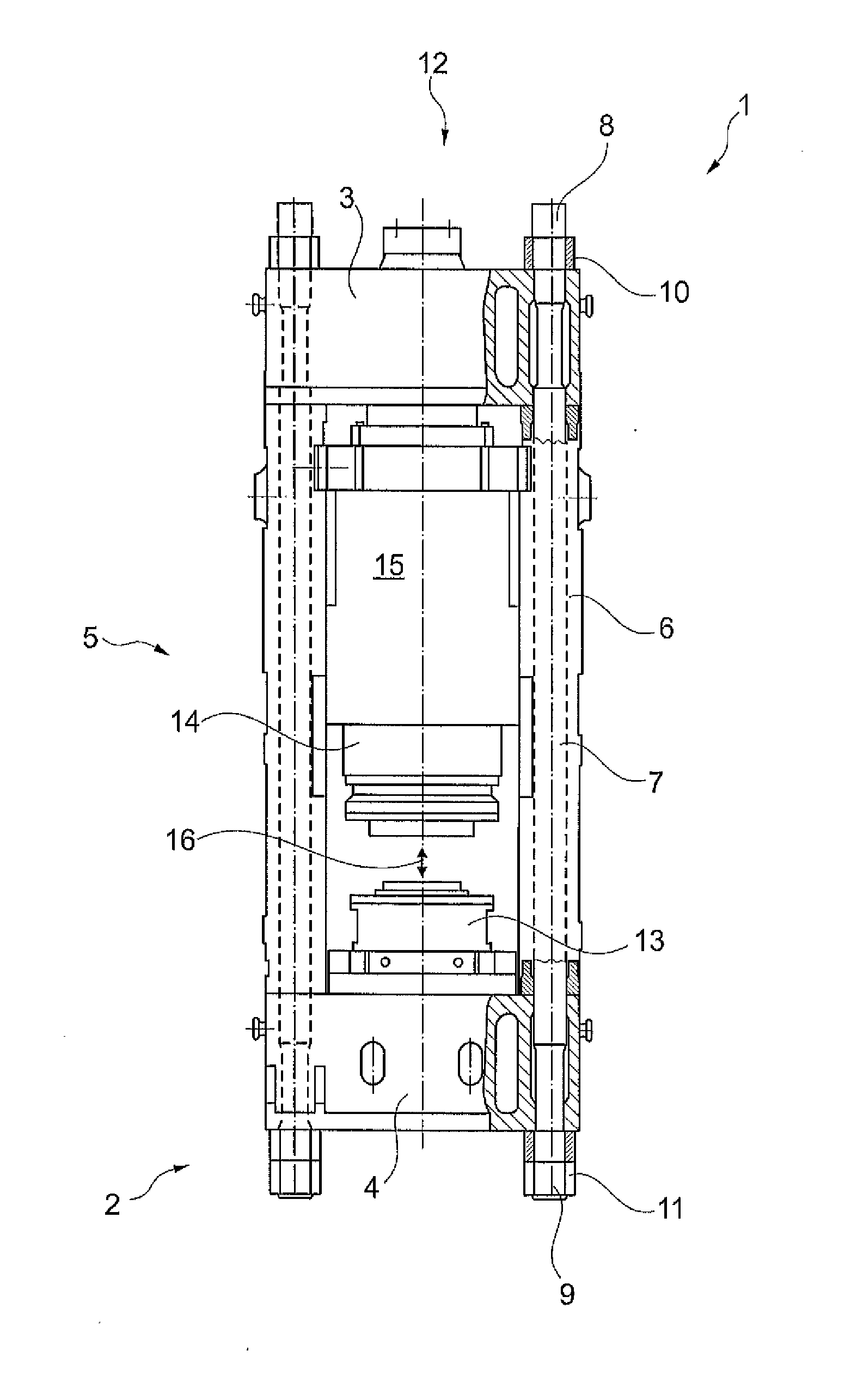

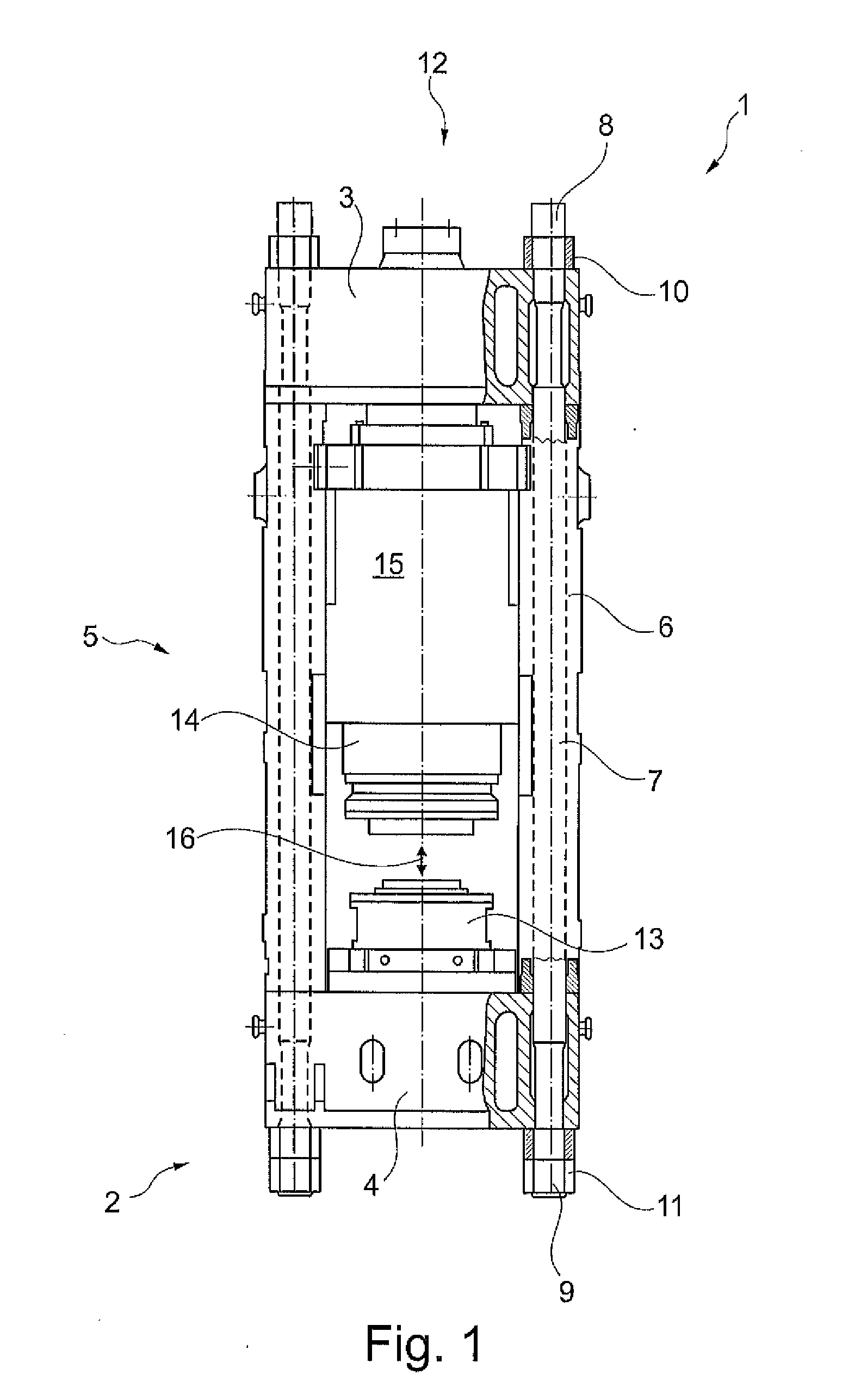

[0071]The press 1 shown in FIG. 1 has a typical structure, known from the state of the art, of a press frame 2, which essentially comprises a cylinder crossbar 3 and a counter-crossbar 4, as well as a stand mechanism 5 composed of four individual pressure supports 6 (numbered only as an example here). A tension rod 7 composed of steel is disposed within each of the pressure supports 6. Each of the tension rods 7 projects beyond the cylinder crossbar 3 and also beyond the counter-crossbar 4 on the outside, so that a tensioning nut 10 or 11 (numbered only as examples here) can be screwed onto the ends 8 and 9, in each instance, of the tension rods 7, in each instance. While the pressure supports 6 space the cylinder crossbar 3 and the counter-crossbar 4 apart from one another, the press frame 2 as a whole is pre-tensioned by means of the tension rods 7. This is done in that the two tensioning nuts 10 and 11 of the tension rod 7, in each instance, are tightened, so that the components ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Force | aaaaa | aaaaa |

| Shape | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com