One-piece decorative trim bezel having plural unpainted finishes

a one-piece, decorative technology, applied in the direction of roofs, manufacturing tools, other domestic objects, etc., can solve the problems of high cost, high risk of squeaking or rattling, and the known two-piece approach suffers, and achieves rapid cooling and high gloss.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019]In the following figures, the same reference numerals will be used to refer to the same components. In the following description, various operating parameters and components are described for different constructed embodiments. These specific parameters and components are included as examples and are not meant to be limiting.

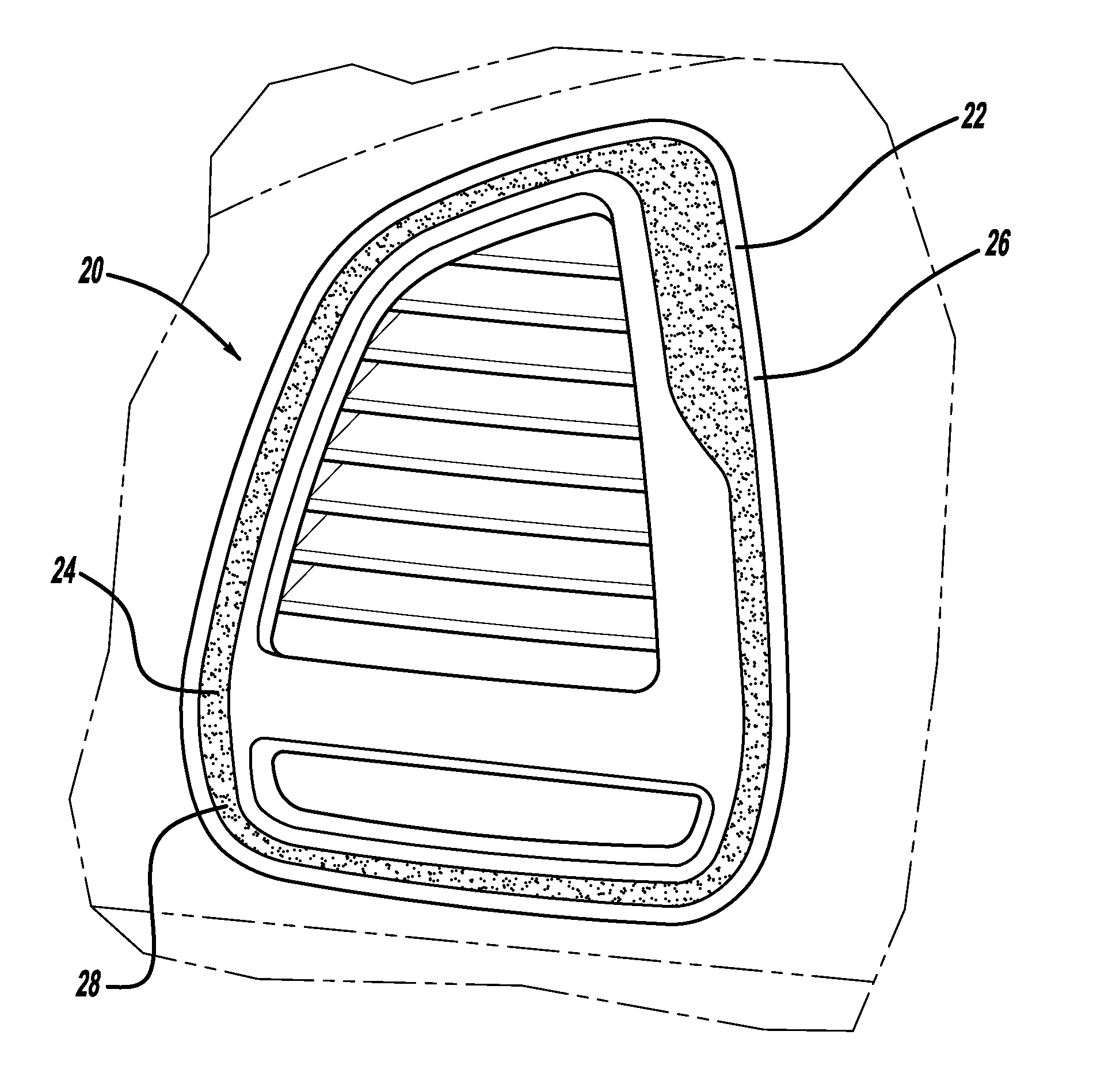

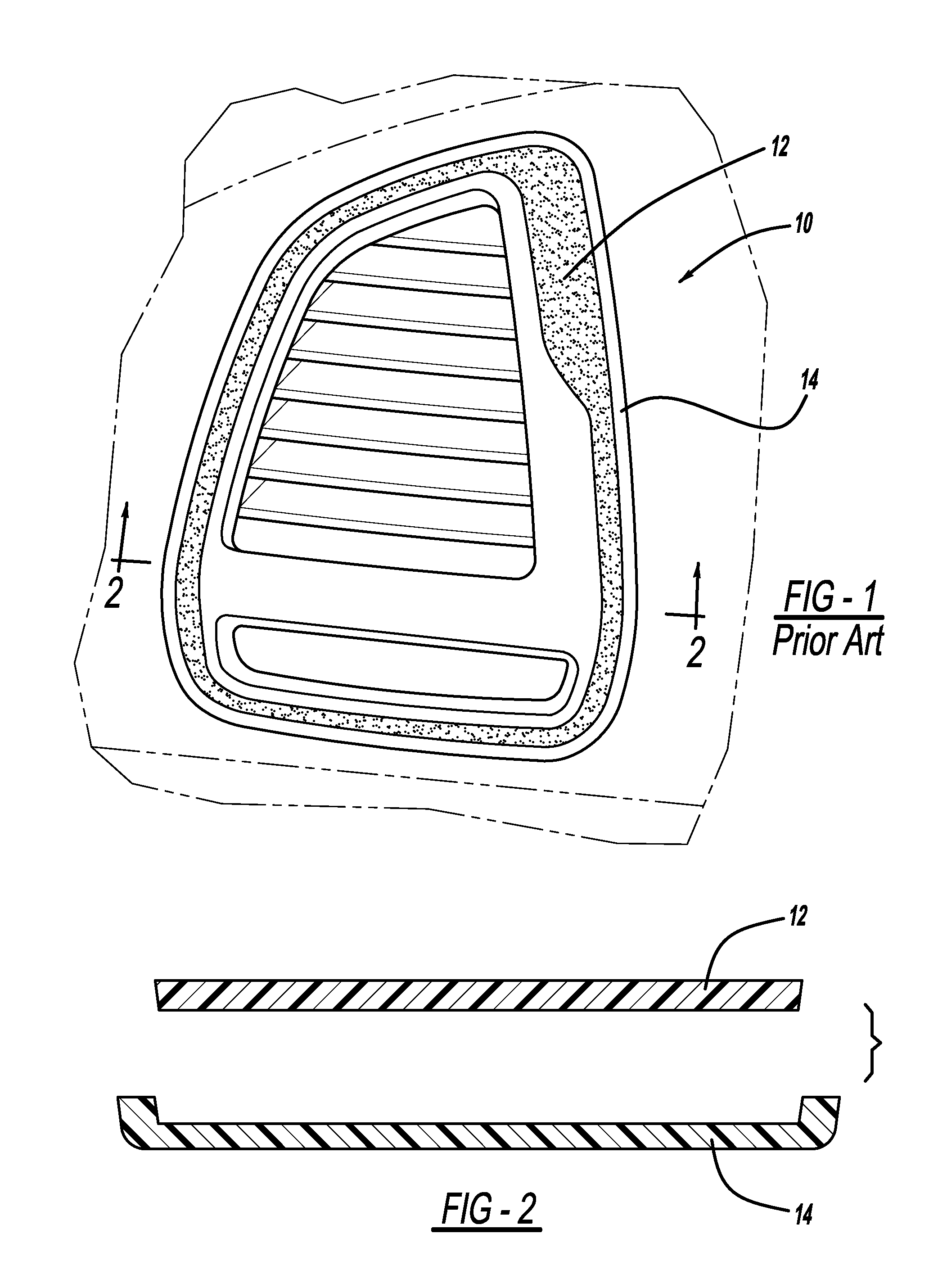

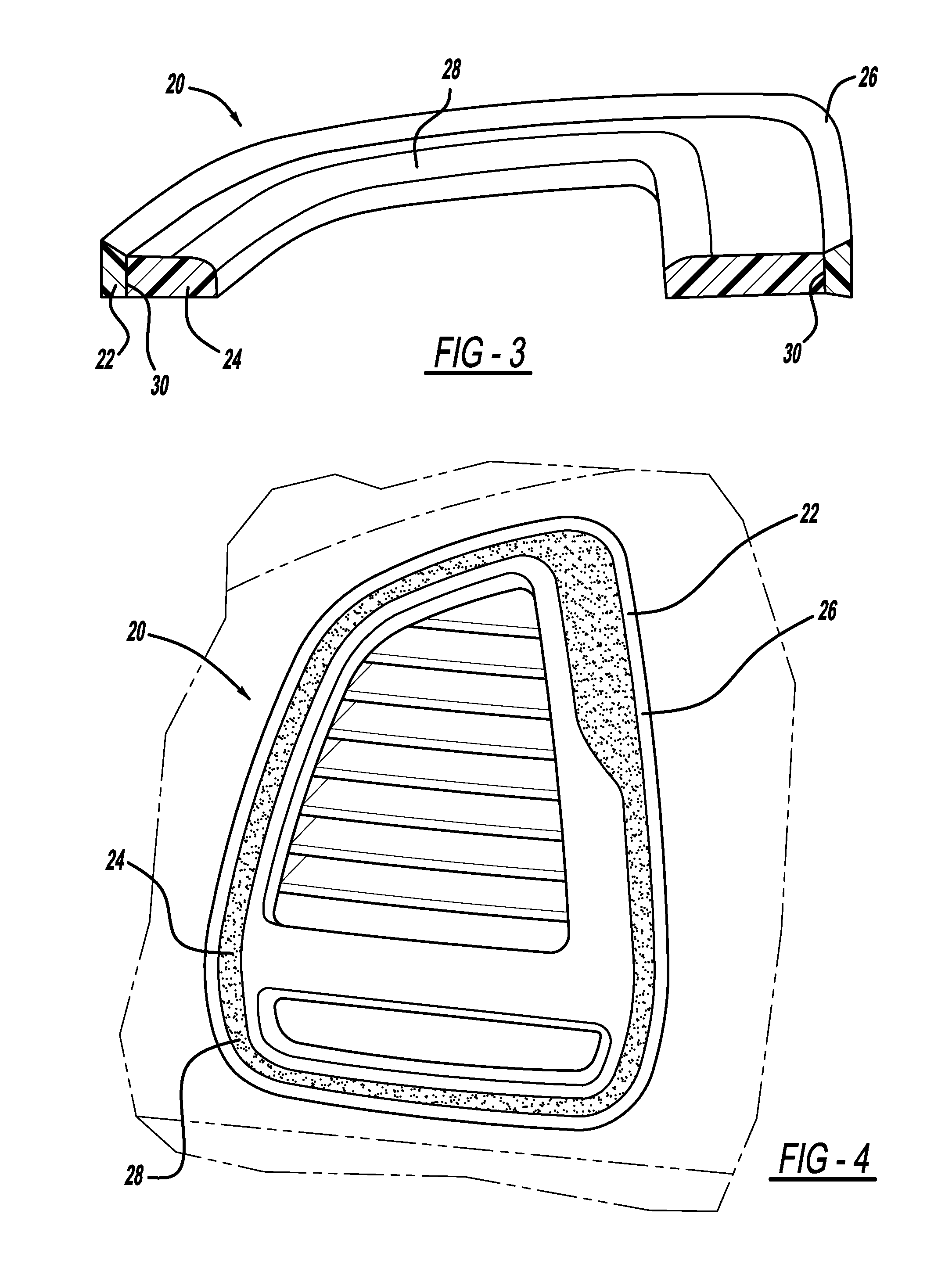

[0020]With reference to FIGS. 3 and 4, an exemplary one-piece trim bezel of the disclosed invention is shown and is generally illustrated as 20. It is to be understood that the shape and overall design of the one-piece trim bezel 20 is only presented for illustrative purposes and is not intended as being limiting as any of a number of designs and configurations can be produced using two co-molded components according to the disclosed invention.

[0021]The one-piece trim bezel 20 of the disclosed invention is formed from two or more co-molded components including at least a plateable portion 22 and a non-plated portion 24. The plateable portion 22 may be forme...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

| Color | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com