Configurable, repairable, and recyclable cargo pallet

a cargo pallet and repairable technology, applied in the field of configurable, repairable, recyclable, adjustable load capacity cargo pallets, can solve the problems of not being able to disclose the design of repairable, recyclable, and reusable cargo pallets, and achieve the effects of preventing deforestation, long useful life of pallets, and positive impact on the environmen

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

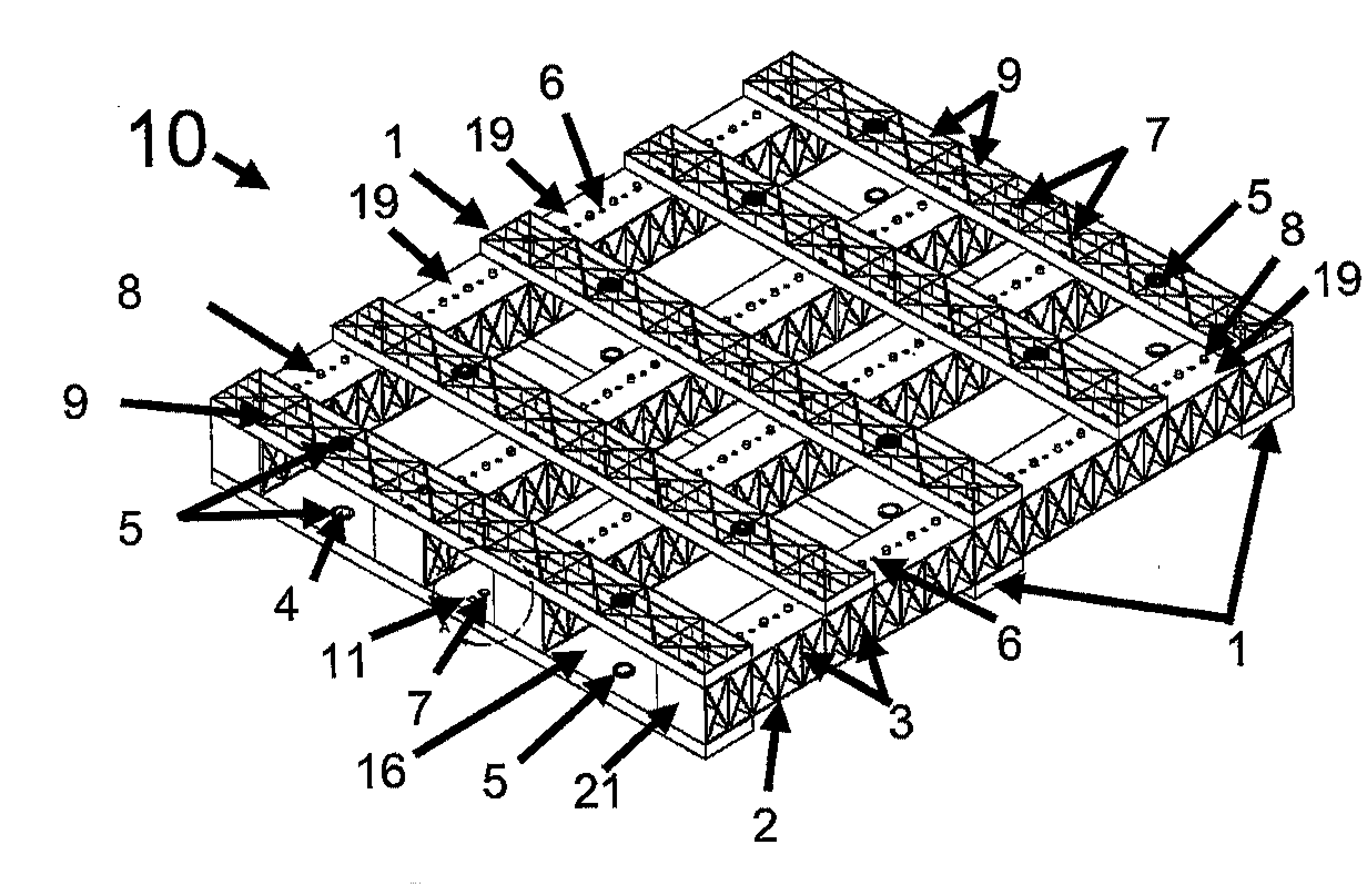

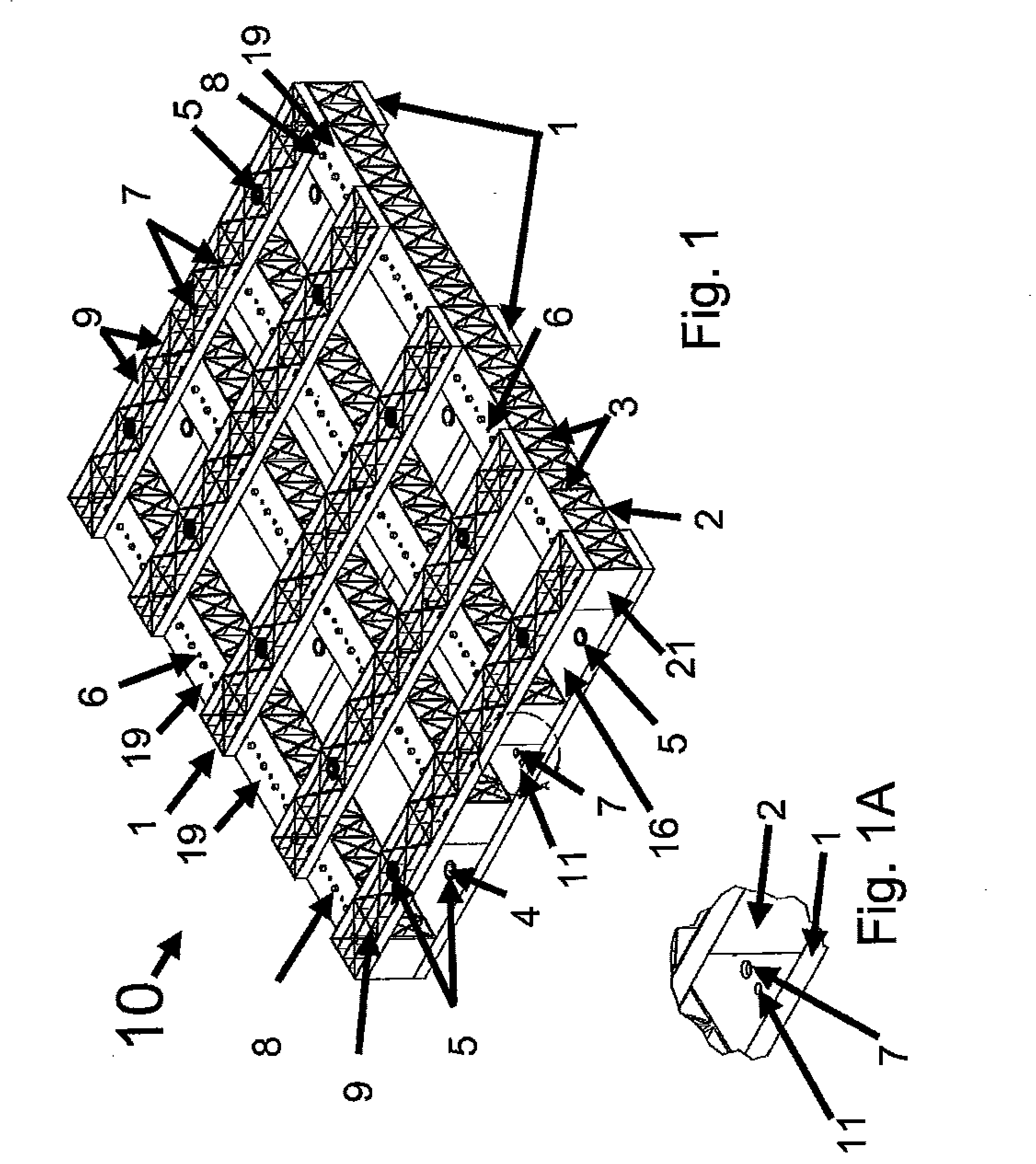

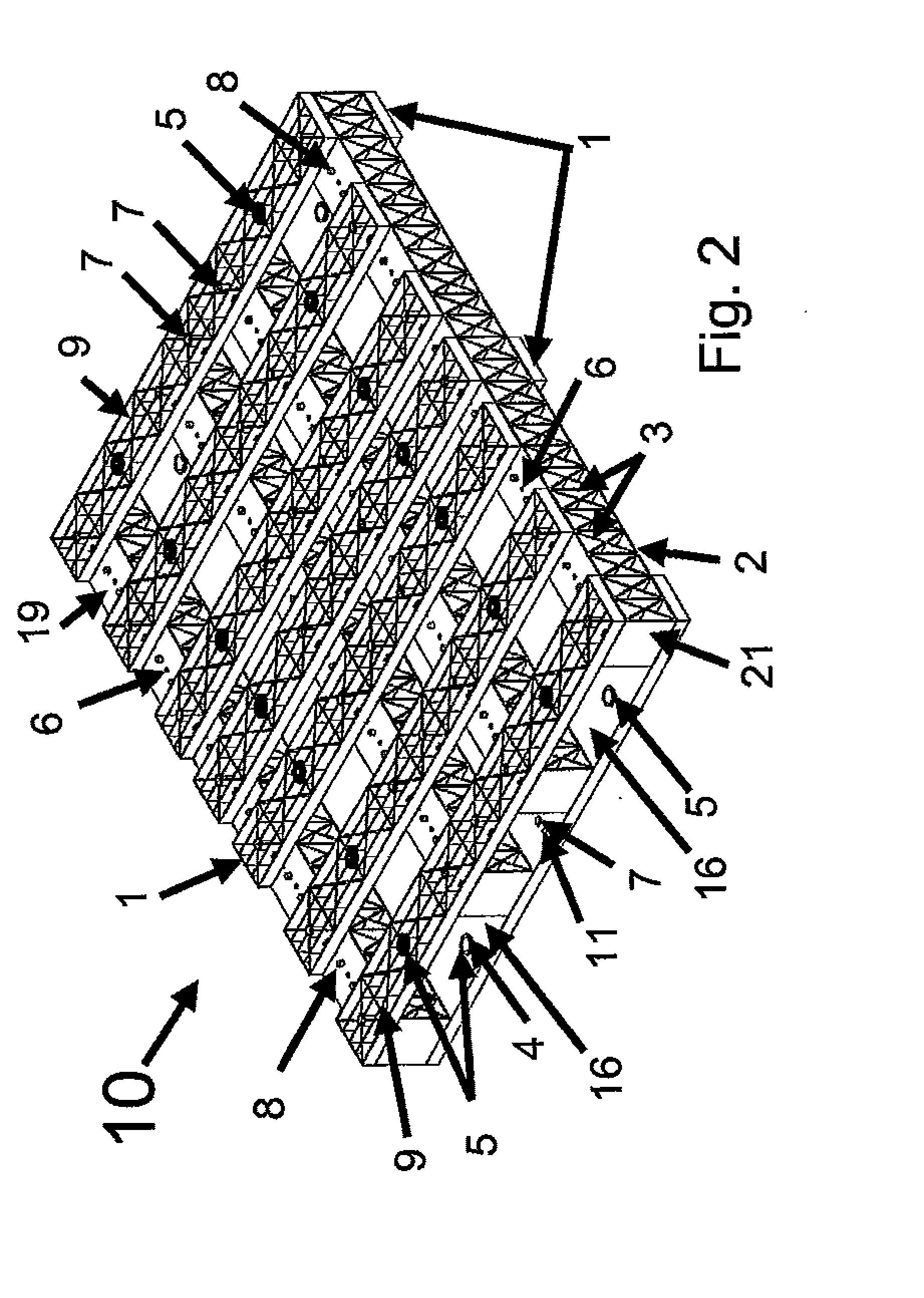

[0041]Considering the characteristics of this invention as explained above, the new pallet 10 is described in more detail next when read in conjunction with the accompanying drawings, in which:

[0042]Referring to FIGS. 1 and 2, this invention is identified as pallet 10 that is configurable for different applications and load capacities depending on the number and the thickness of the walls of the central beams 2 and platform members 1 and also depending on the thickness of the reinforcing ribs 3 and 9. Several central beams 2 are placed parallel to each other and connected with platform members 1 at the top and at the bottom sides of the beams 2. As shown in FIGS. 1 and 2, the number of platform members 1 at the top of beams 2 could be the same as or different to the number of members 1 at the bottom of beams 2. The pallet model is specified by three numbers indicating the number of platform members 1 at the top, the number of central beams 2, and the number of platform members 1 at ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com