Dispenser for wafer pockets containing wafers and wafer pocket assembly

a technology of dispensers and wafers, which is applied in the direction of packaging foodstuffs, pharmaceutical containers, packaged goods types, etc., can solve the problems of user difficulty in filling the secondary package with wafer pockets, complicated wafer primary and secondary packages described above, and considerable manufacturing costs, etc., to achieve convenient use, reduce manufacturing costs, and facilitate the effect of pulling apar

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

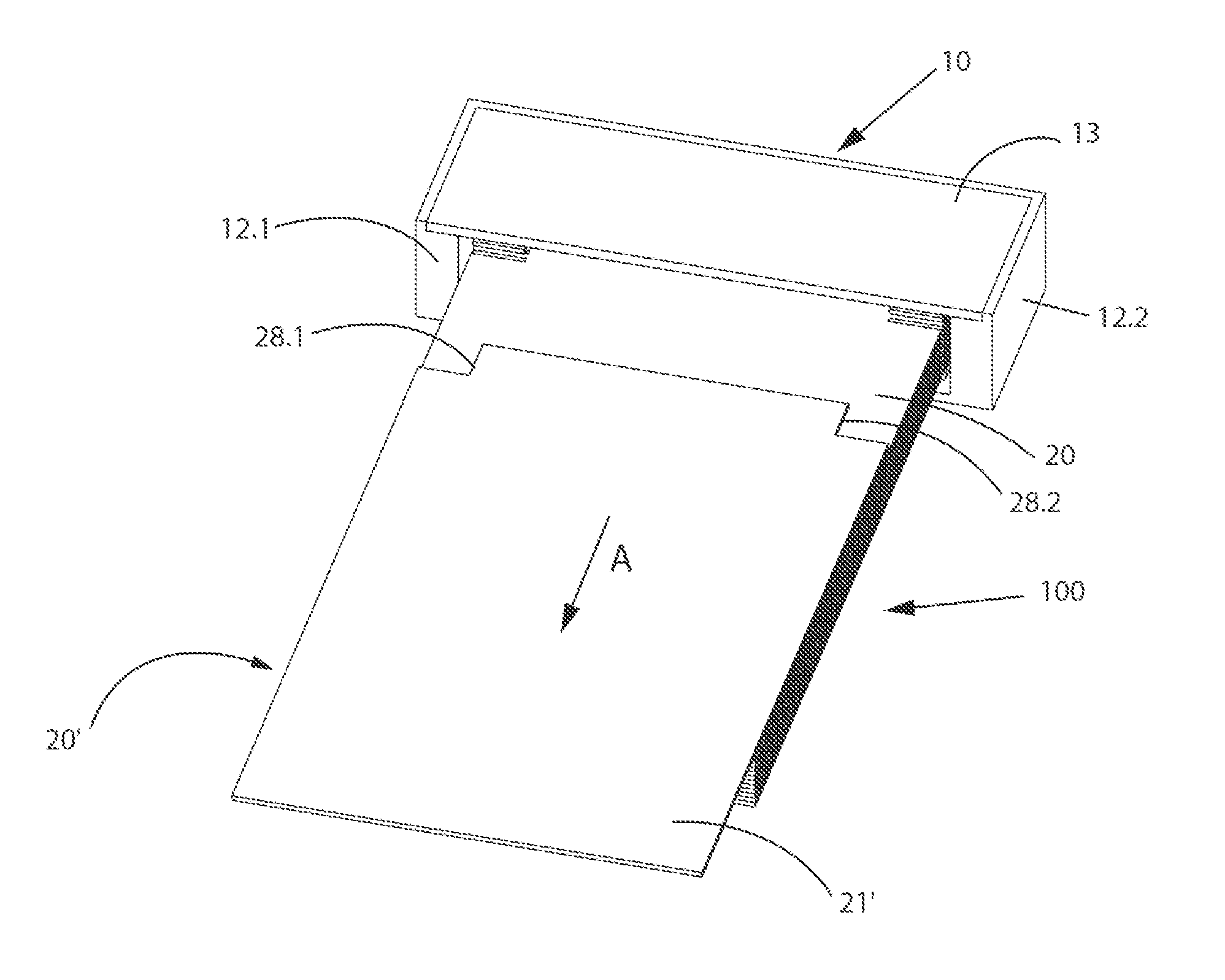

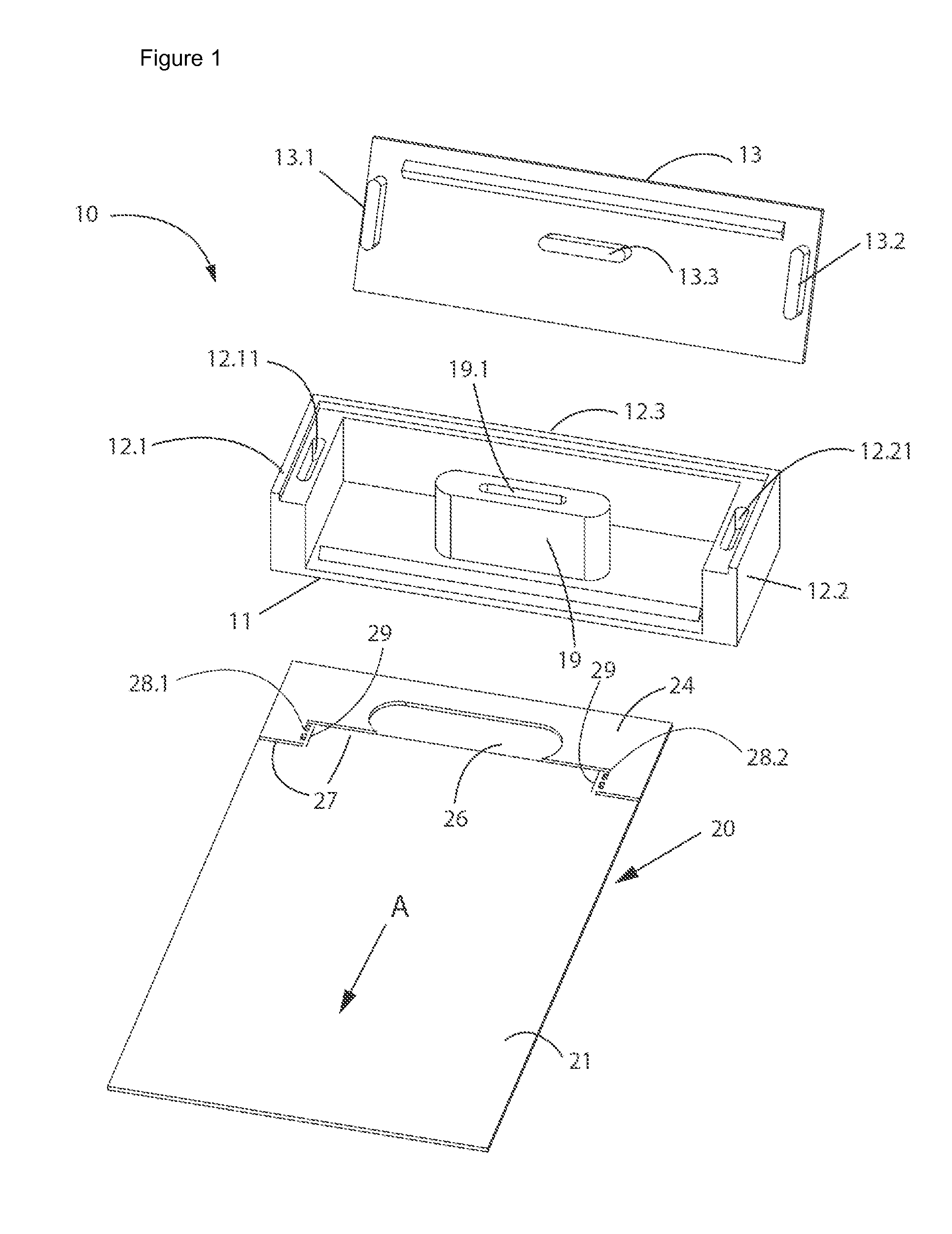

[0054]FIG. 1 shows a perspective view of a holding block which is open toward the top with a separately illustrated cover plate and a wafer pocket which can be inserted into the holding block, in a first embodiment according to the invention;

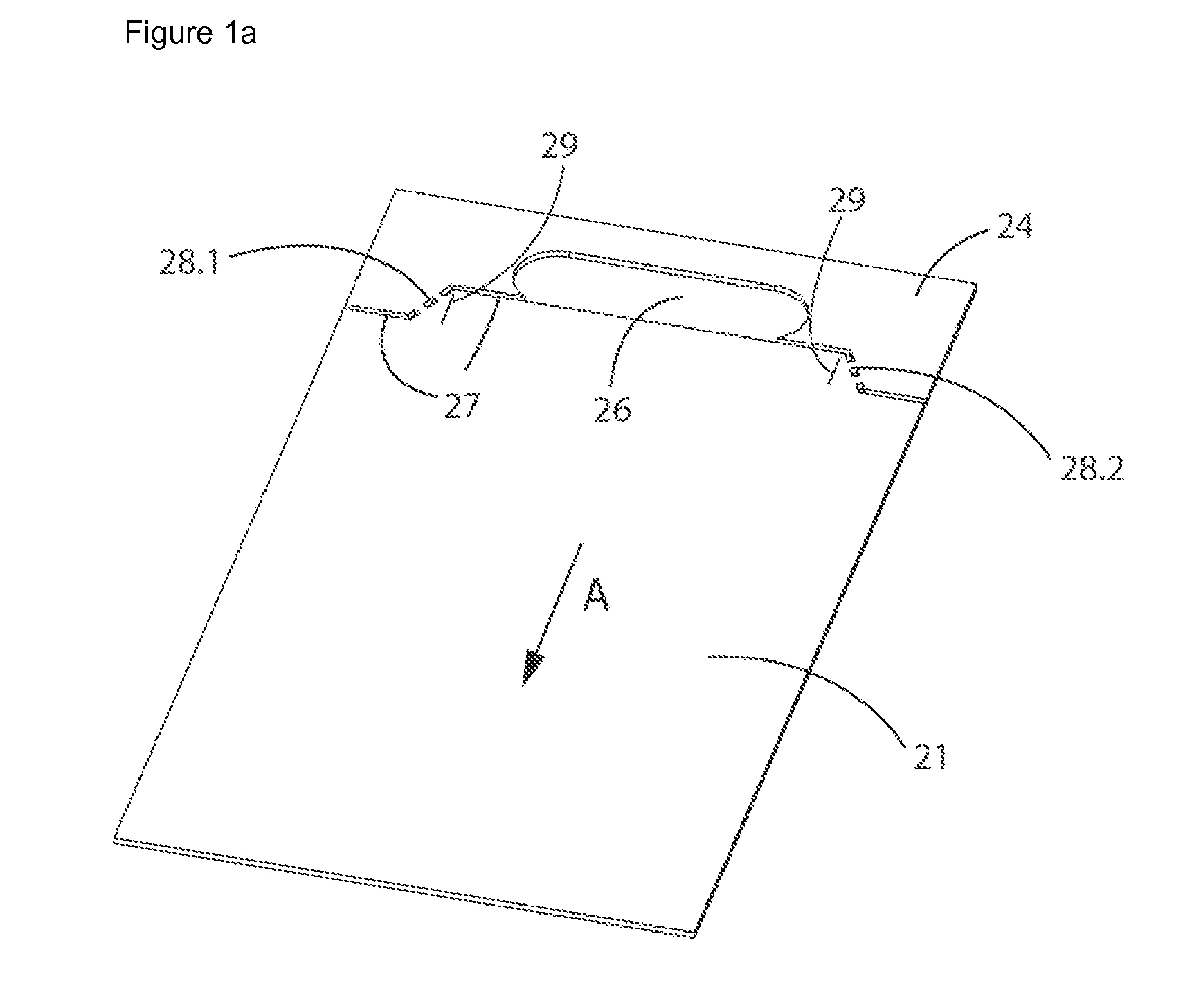

[0055]FIG. 1a shows a perspective view of a wafer pocket in a variant of that in FIG. 1;

[0056]FIG. 2 shows a perspective illustration of a wafer pocket booklet which is obtained by mounting a wafer pocket stack in a holding block, according to the first embodiment according to the invention;

[0057]FIG. 3 shows a perspective illustration of the wafer pocket booklet from FIG. 2 after the uppermost wafer pocket has been torn off;

second embodiment

[0058]FIG. 4 shows a perspective view of a holding block which is open toward the top and a wafer pocket which can be inserted into the holding block, in a second embodiment according to the invention;

third embodiment

[0059]FIG. 5 shows a perspective view of a holding block which is open toward the top and a wafer pocket which can be inserted into the holding block, in a third embodiment according to the invention;

[0060]FIG. 6 shows a perspective view of a wafer pocket booklet composed of a stack of wafer pockets, combined by means of a holding block, according to the second or the third embodiment according to the invention;

[0061]FIG. 7 shows a perspective view of a wafer pocket booklet composed of a stack of wafer pockets which are combined by means of a holding block, in which stack the uppermost wafer pocket has been separated out from the holding block, according to the second or the third embodiment according to the invention;

[0062]FIG. 8 shows a perspective view of the base and lid parts forming a dispenser according to the invention, according to the second embodiment according to the invention;

[0063]FIG. 9 shows a perspective view of a dispenser according to the invention in the ready-to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com