Transportable, environmentally-controlled equipment enclosure

a technology of environmentally controlled equipment and equipment enclosures, which is applied in the direction of electrical apparatus construction details, indirect heat exchangers, lighting and heating apparatus, etc., can solve the problems of power consumption of equipment sites, significant power consumption of cooling systems, and the most existing “brick and mortar” sites running out of power capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

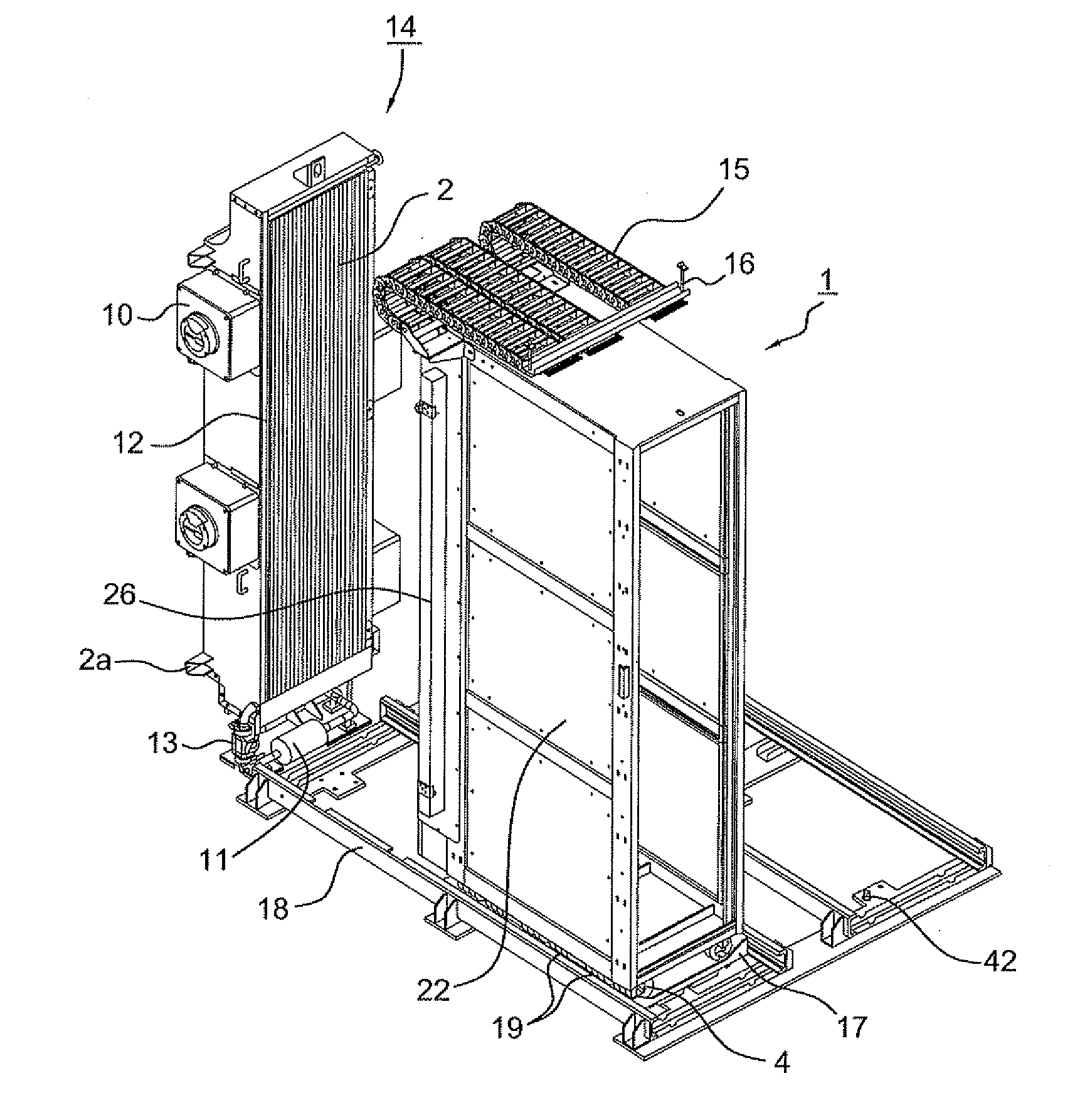

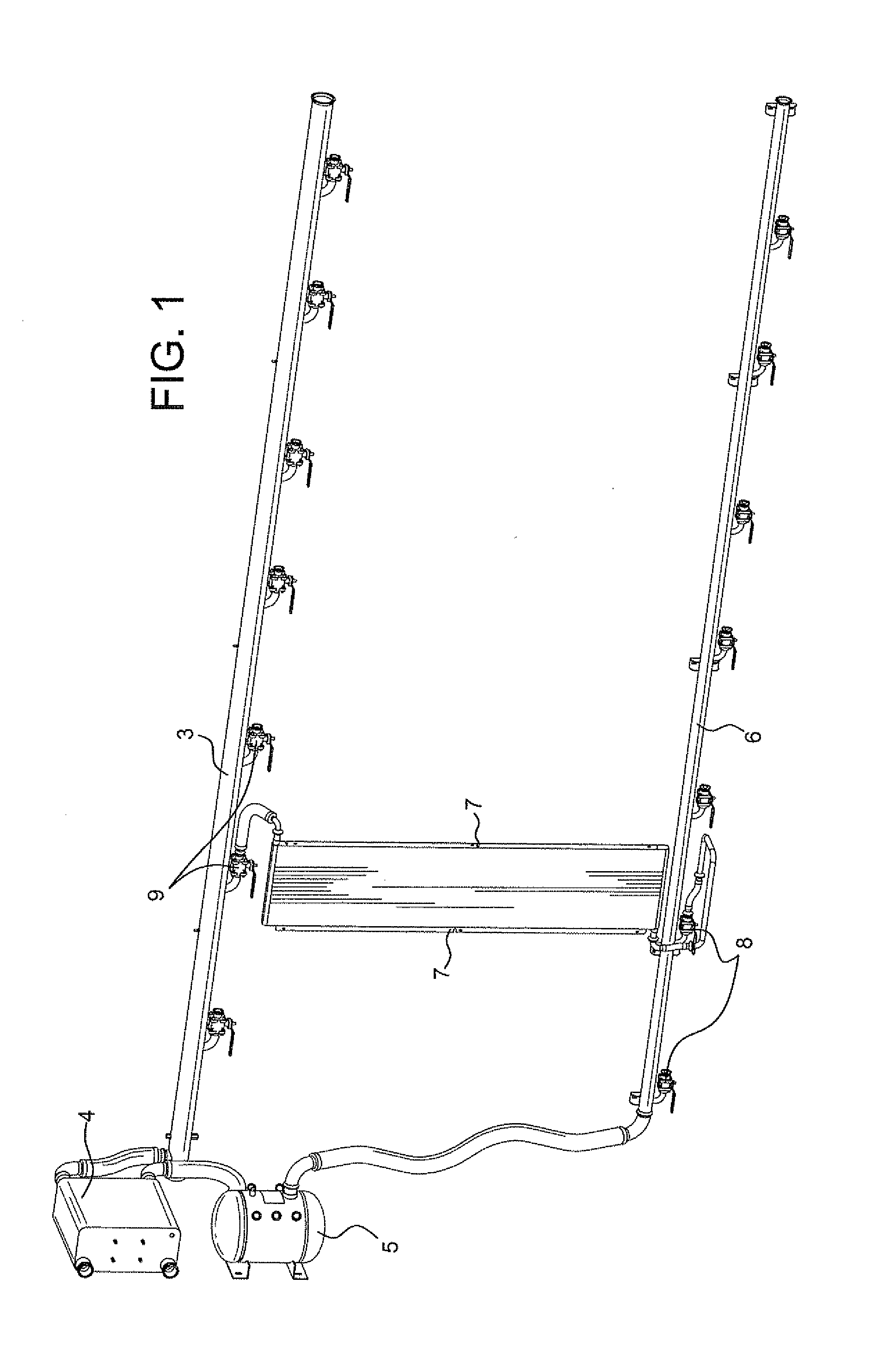

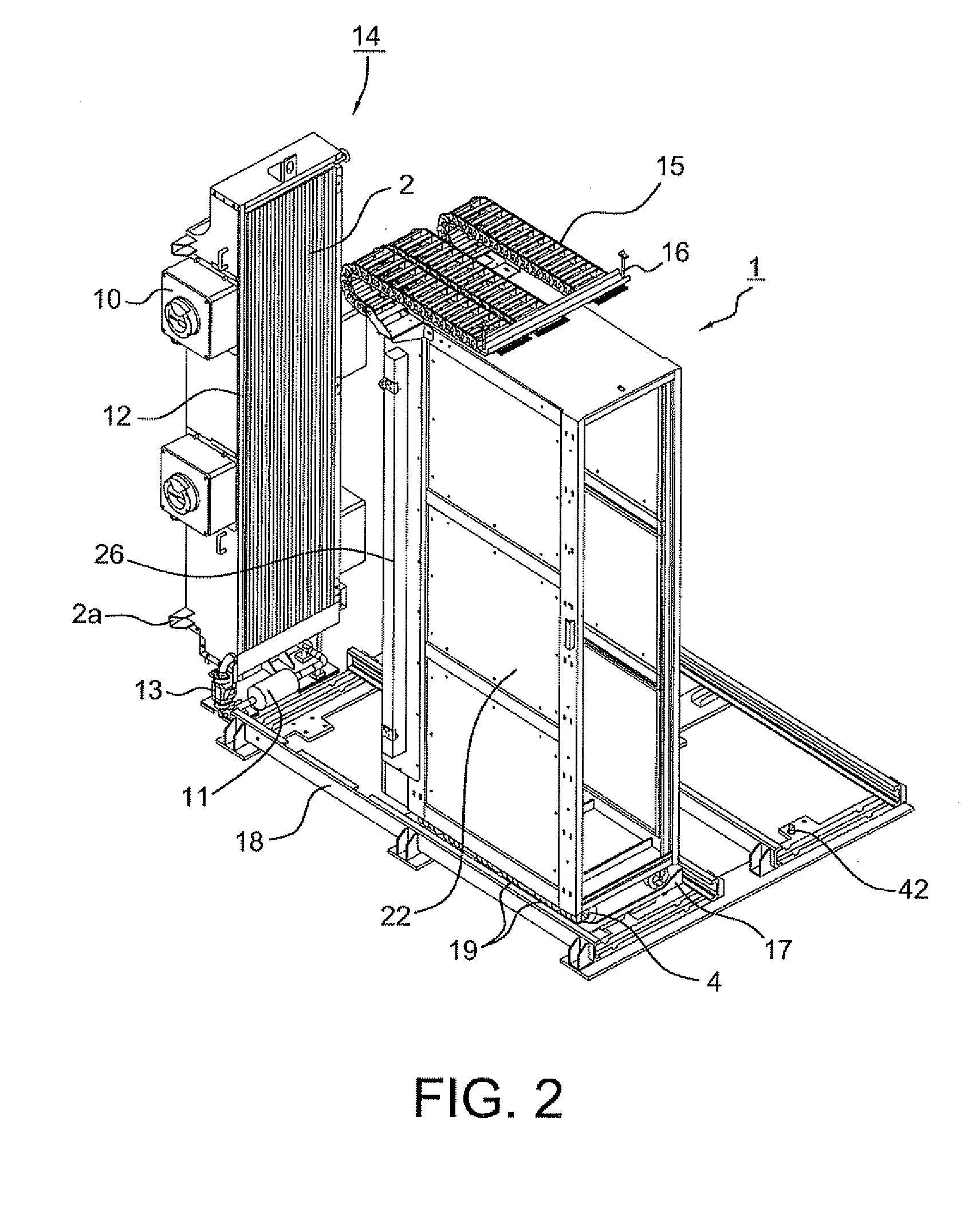

[0045]The preferred embodiments of the invention may be implemented in any transportable, environmentally controlled equipment enclosure, as well as in static or non-transportable equipment enclosures. While specific features of the enclosure exterior and layout are preferred, these features should in general be taken as exemplary and not limiting. In particular, the cooling system and rack mounting arrangements may be separately applicable to a wide variety of different equipment enclosure types, as may various safety and other improvements described below and depicted in the accompanying drawings.

[0046]a. Pump-Less Cooling System

[0047]The cooling system of this preferred embodiment of the invention differs from conventional equipment enclosure cooling systems in that it does not require either a central coolant pump or distributed pumps for the respective enclosures, thereby achieving both power savings and reduced equipment / maintenance costs.

[0048]As illustrated in FIG. 1, the pu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com