Highly pure copper anode for electrolytic copper plating, method for manufacturing same, and electrolytic copper plating method

a technology of high-purity copper and anode, which is applied in the direction of electrolytic devices, etc., can solve the problems of increasing the occurrence of plating defects, and achieve the effect of suppressing the formation of anode slime and preventing the formation of plating defects, such as nodular deposits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

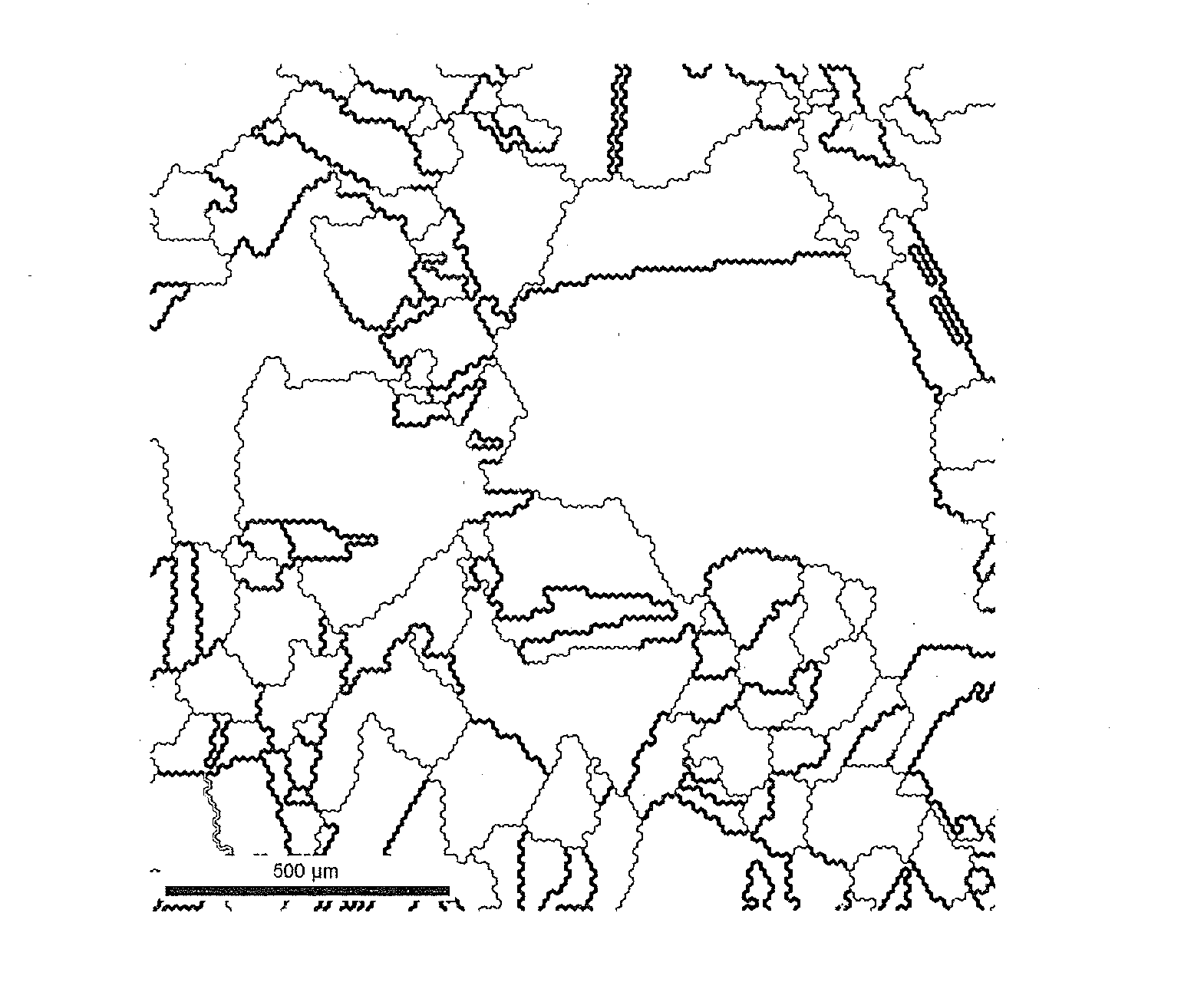

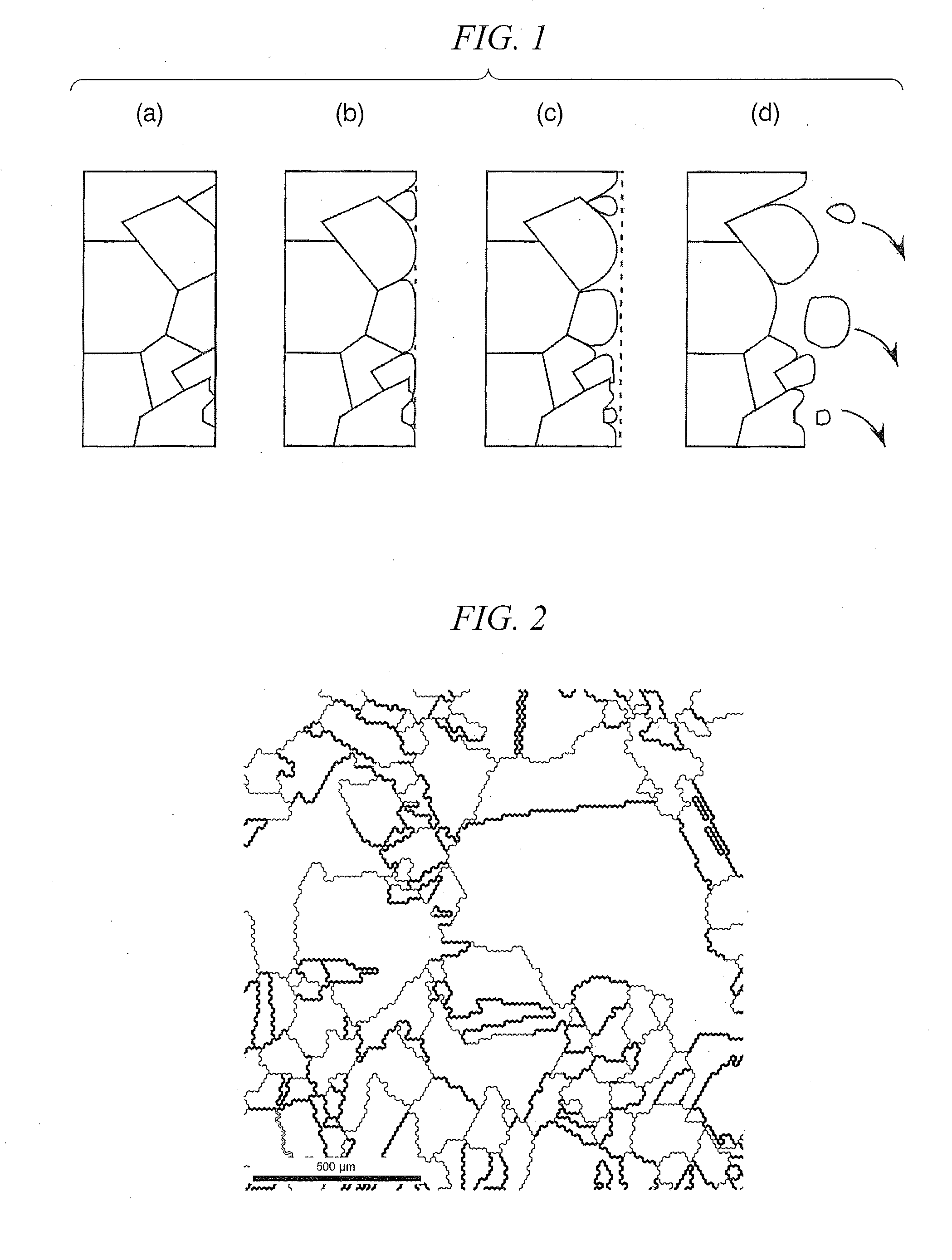

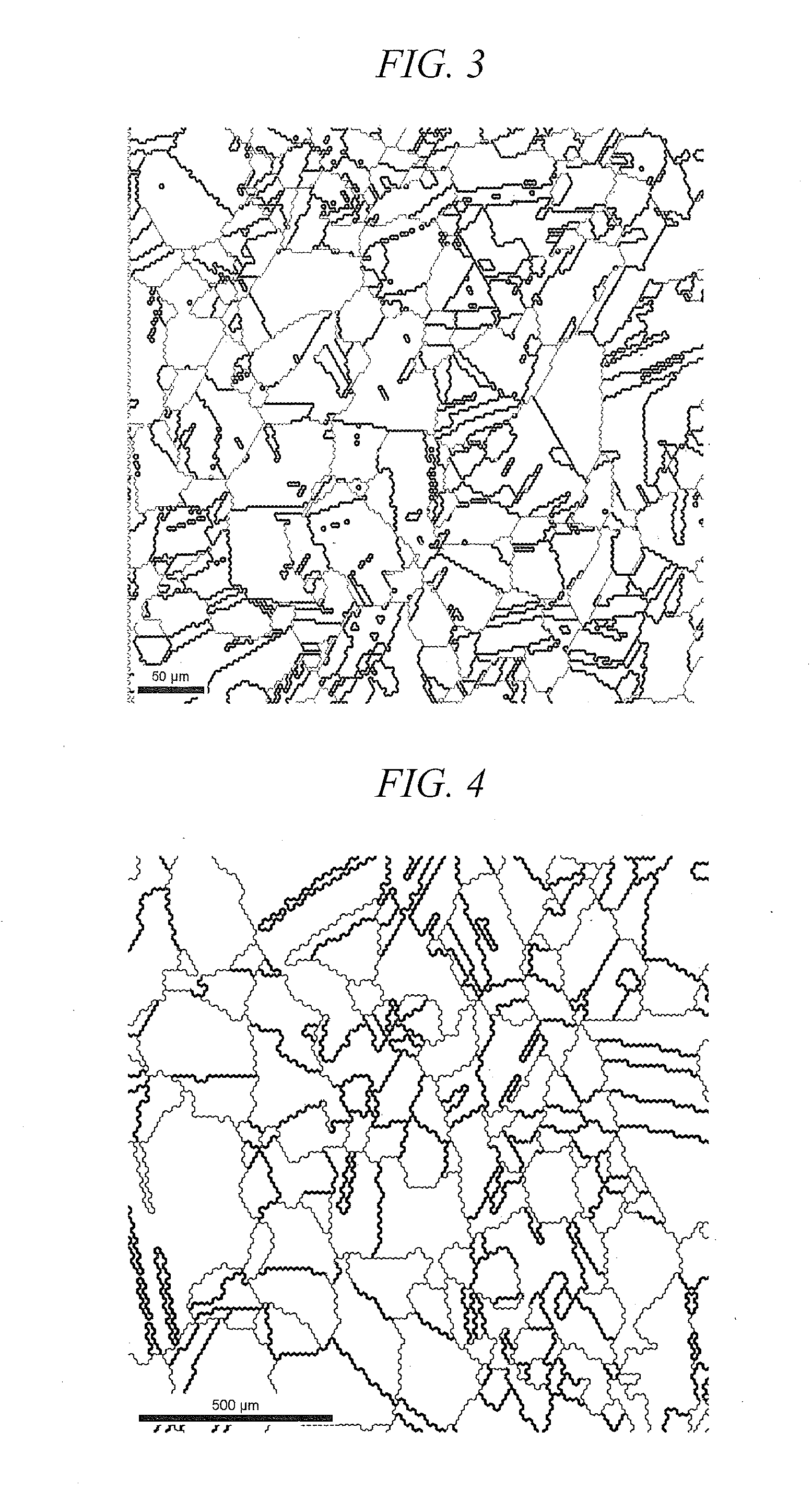

Image

Examples

examples

[0060]Highly pure copper anodes (referred to as anodes of the present invention) 1 to 20 having the prescribed sizes shown in Table 3 were manufactured. The anodes of the present invention 1 to 20 were manufactured by carrying out hot working (temperature, processing method, processing rate), cold working (processing method, processing rate) and / or recrystallization heat treatment (temperature, time) under the conditions shown in Table 1, or repeating these processes on recrystallized materials or cast materials of highly pure copper of the tough pitch pure copper (TPC) with a purity of 99.9% by mass or higher, the highly pure copper (4N OFC) with a purity of 99.99% by mass or higher, the highly pure copper (5N OFC) with a purity of 99.999% by mass or higher, and the highly pure copper (6N OFC) with a purity of 99.9999% by mass or higher shown in Table 1. After the heat treatment, the anodes 1 to 20 of the present invention were water-cooled.

[0061]In the wire-drawing-cold-working pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com