Feed forward controlled voltage to current source for LED driver

a technology of current source and led driver, which is applied in the direction of dc-ac conversion without reversal, process and machine control, instruments, etc., can solve the problems of poor compatibility with phase controlled dimmers, poor power factor, and negative resistance inputs which are prone to oscillations, so as to minimize the dimming problem and efficiently drive the led

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

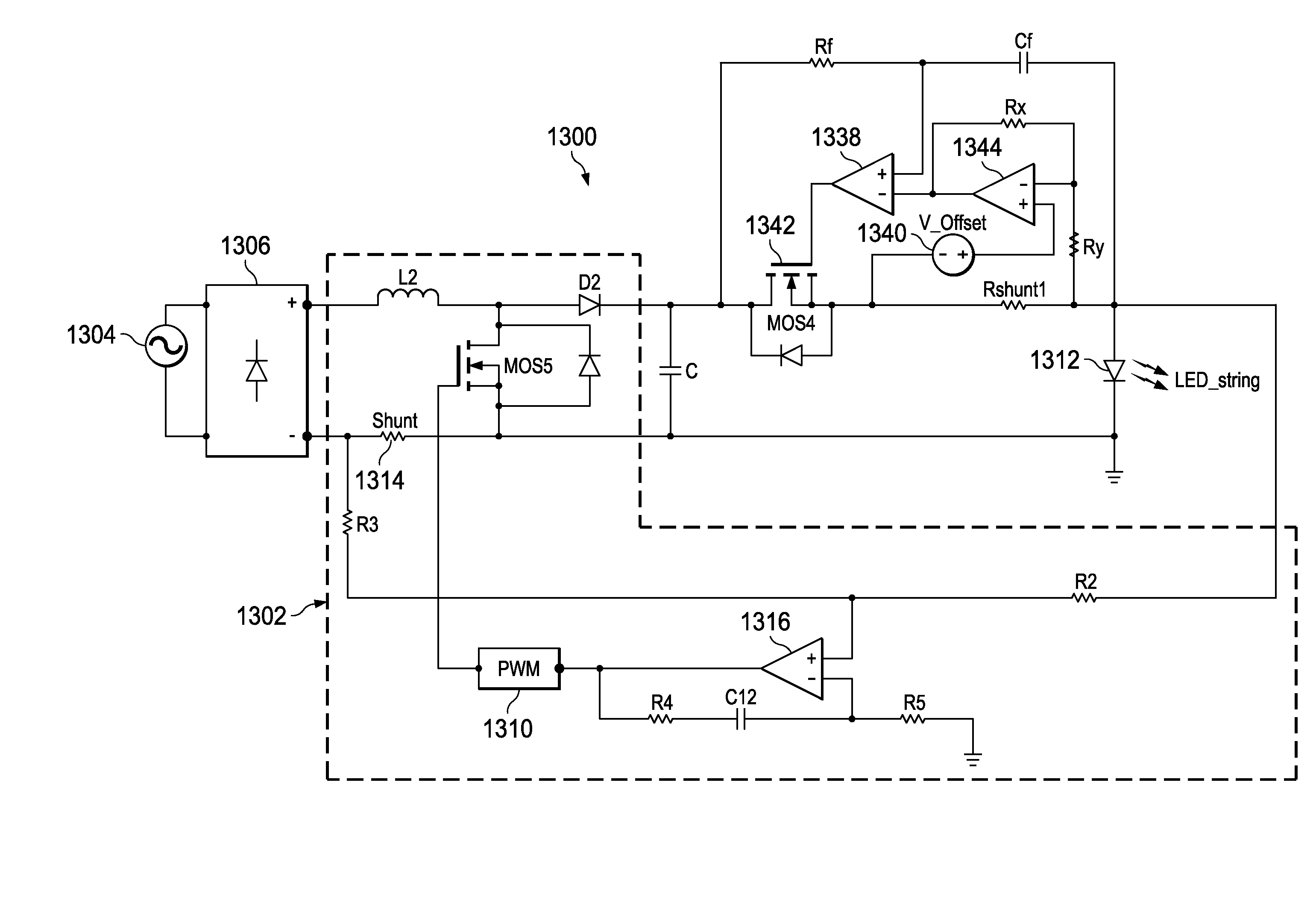

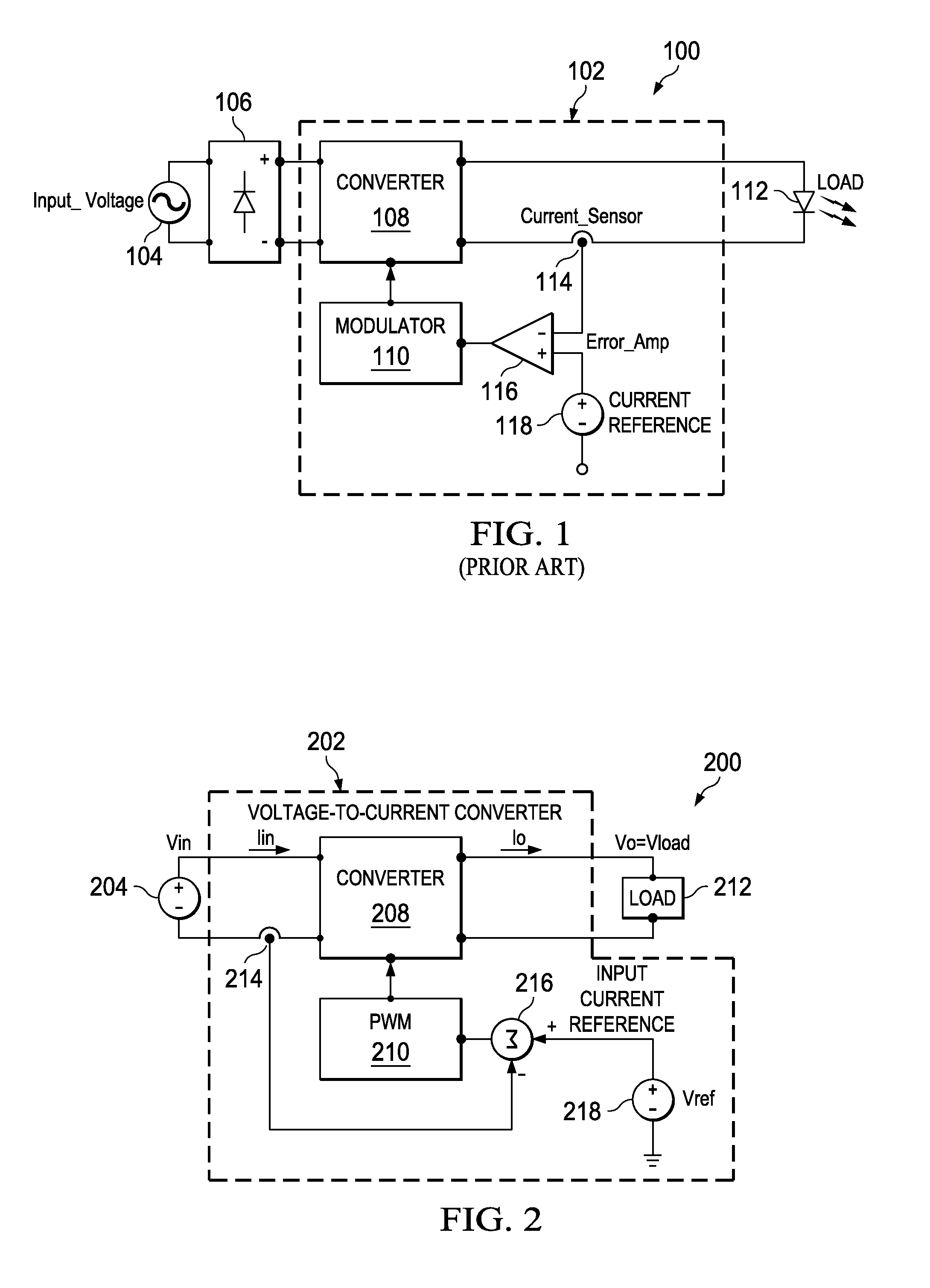

[0027]An aspect of the present invention is shown generally in FIG. 2 as 200. In FIG. 2, a DC input 204 is shown instead of of the AC input 104, shown in FIG. 1. The DC input can be an AC source coupled to a DC rectifier, such as a full wave rectifier 106, shown in FIG. 1, for example. The DC input voltage 204 is applied to a DC to DC converter 208 of LED driver circuit 200. The converter can utilize any converter topology, including isolated and nonisolated converters, and any control algorithm for controlling the input current. A current sensor 214 is placed in series between the negative input to the converter and the negative output of the power source. The output of converter 208 is connected to a load 212, which may be an LED or LED string, for example. The load could also be a DC to AC converter operating an AC load, such as a flourescent tube, for example. The converter may be controlled by a pulse width modulation (PWM) modulator circuit 210 which receives the output of an ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com