Driving Engine (Water Turbine) Of Hydrokinetic Floating Power Plant With Enhanced Efficiency Degree, And Hydrokinetic Floating Power Plant Module

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

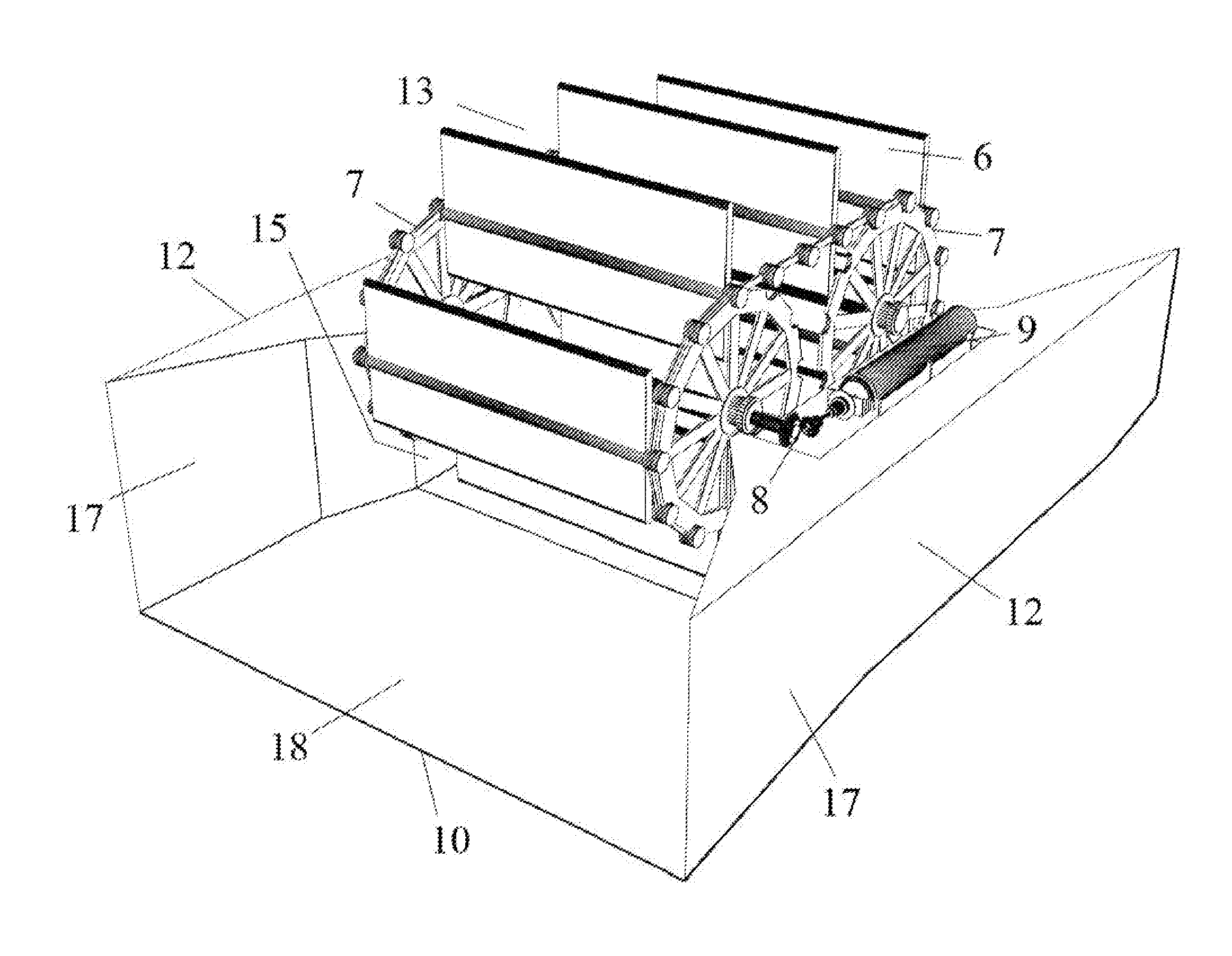

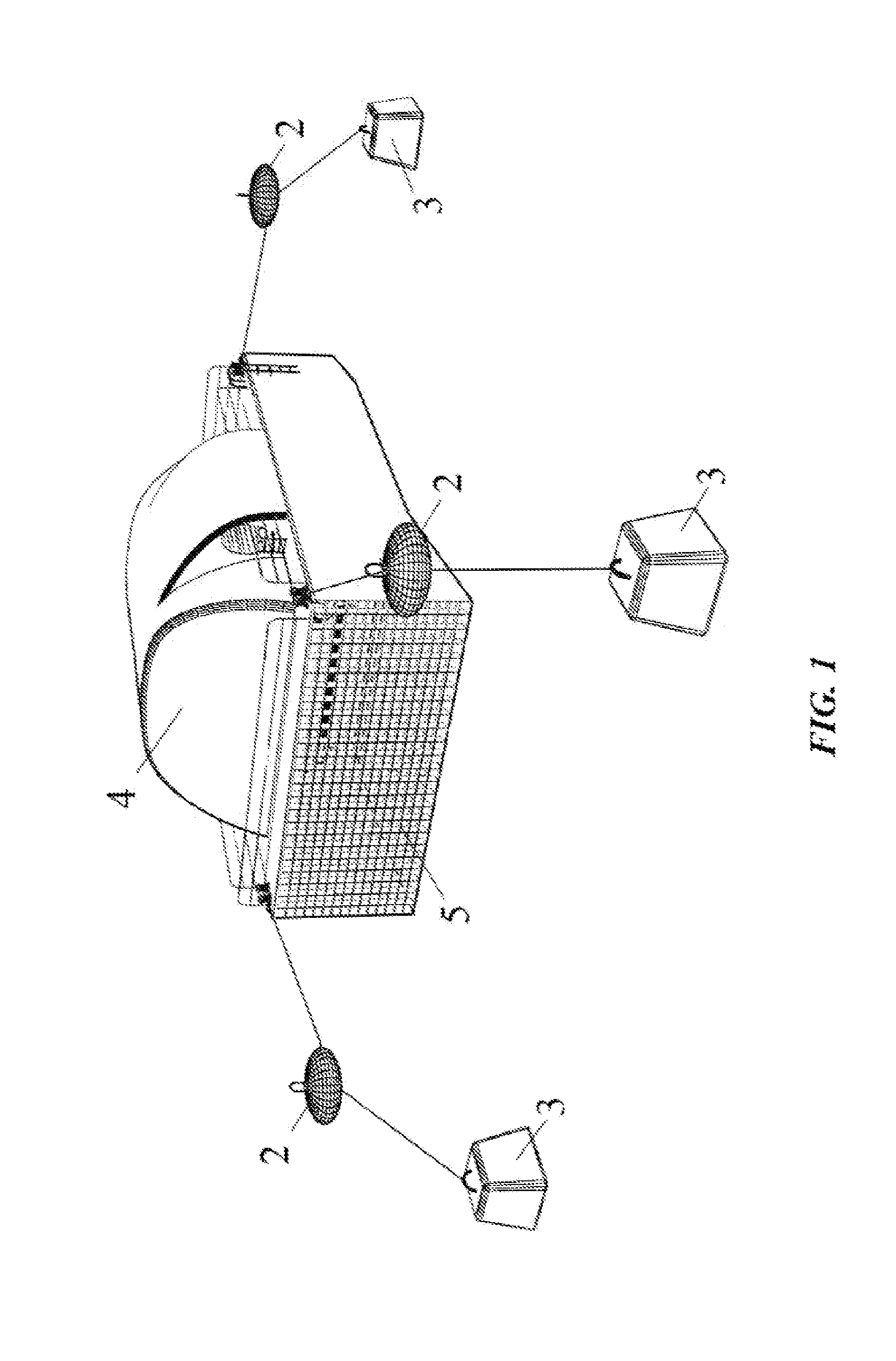

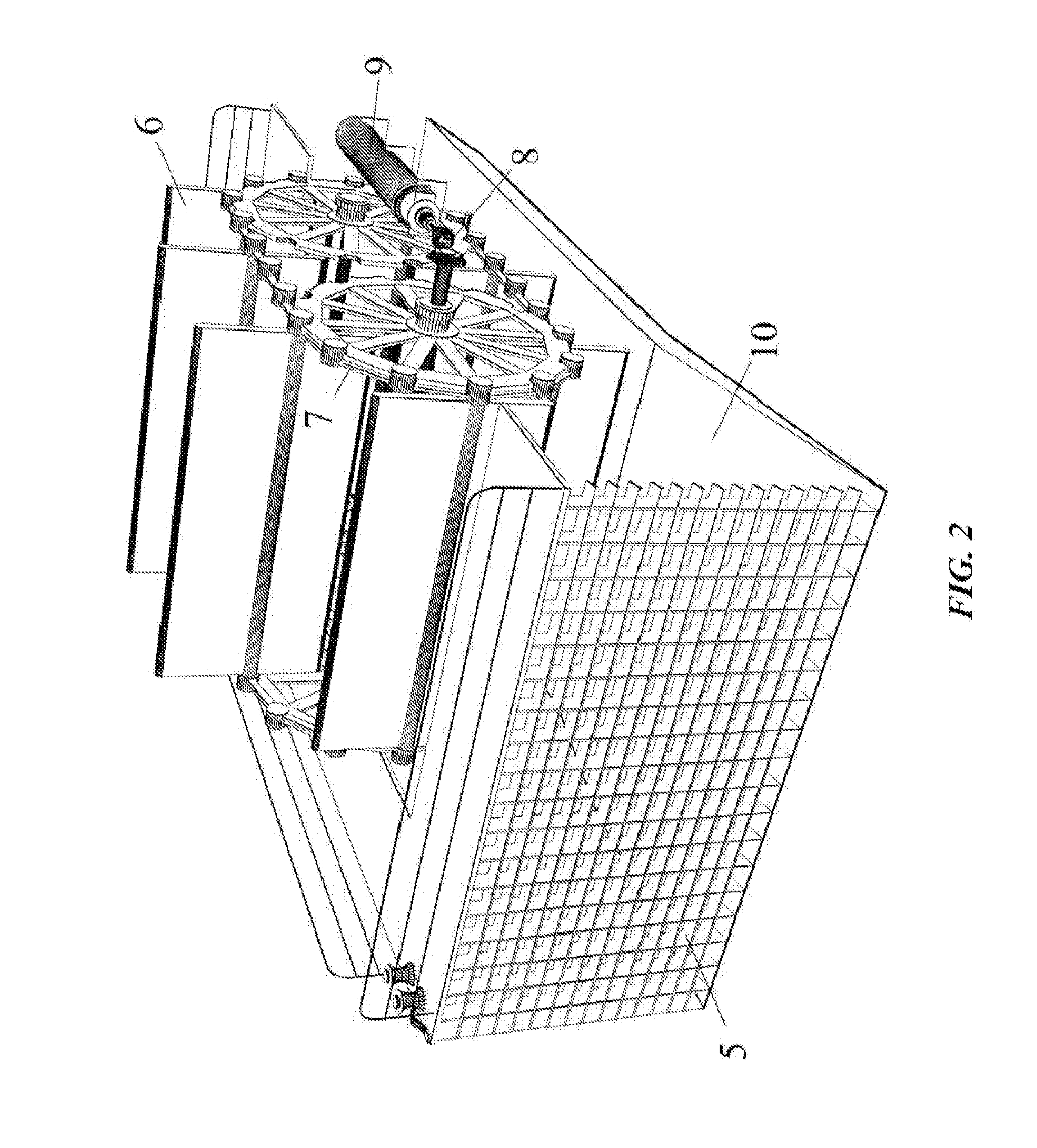

[0036]The details and parameters of the driving engine elements which contribute to an improvement of the hydrokinetic driving engine efficiency and the hydrokinetic floating power plant module efficiency were determined by implementation of commercial CDF (Computational Fluid Dynamics) software. A 2-D flow of a water stream around and within the hydrokinetic floating power plant was simulated in order to examine the influence of geometry and position of the driving engine in the water stream in system efficiency. The k-ε model of turbulence and two kinds of flow were studied, particularly:[0037]non-stationary flow with floating blades and given velocity, and[0038]stationary flow with imposed given velocity at blade equal to blade velocity.

[0039]In all cases undisturbed water incoming velocity was given and equals to 2 m / s. The following parameters were studied to analyze their impact on efficiency:[0040]1) distance t between two adjacent blades being 0.8, 3.0 and 6.0 m;[0041]2) gap...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap