Dursban water emulsion without organic solvent and preparation method thereof

An organic solvent and chlorpyrifos technology, which is applied in the water emulsion field of broad-spectrum insecticide and acaricide chlorpyrifos, can solve the problems of large amount of surfactants, easy stratification, organic solvents are not completely replaced by water, etc., and achieve environmental protection benefits Obvious, water consumption increase effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

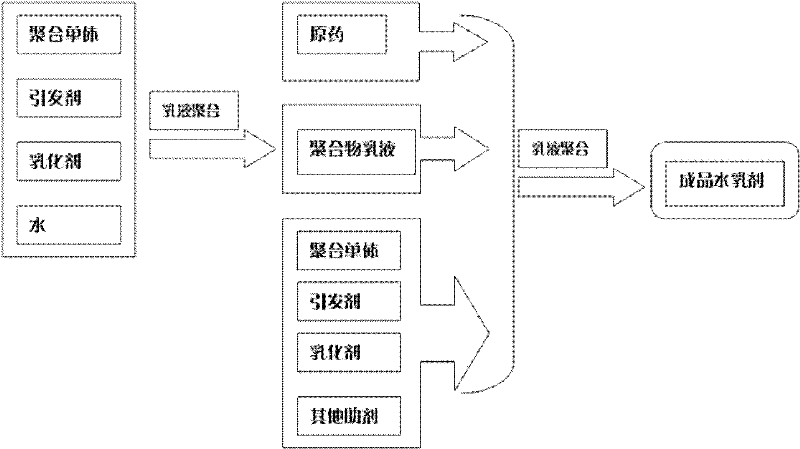

Method used

Image

Examples

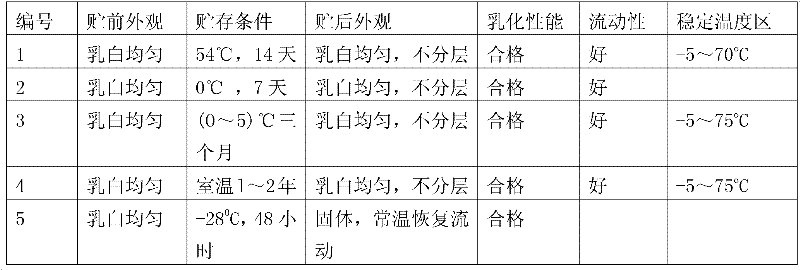

Embodiment 1

[0026] Add 25g op-10 (emulsifier) into the reaction kettle, then add 1500mL tap water, stir and heat up to 60°C, stir for 5 minutes to make it react and dissolve, add 4.1g potassium persulfate as polymerization initiator, stir well Add 180mL methyl acrylate and react at 60°C for 3h. Then add 135g of the original drug of chlorpyrifos, and add 10mL of antifreeze ethylene glycol at the same time, and continue to react for 3h. After the reaction is completed and cooled, 0.5 g of polymerization inhibitor p-benzoquinone is added, and it is poured into a container to obtain the required chlorpyrifos emulsion in water.

Embodiment 2

[0028] Add 80g of sodium dodecylbenzenesulfonate (emulsifier) to the reaction kettle, then add 1300mL of tap water, stir to make it react and dissolve, add 12.5g of benzoyl peroxide as a polymerization initiator, add 900mL of benzene after stirring evenly Ethylene, reacted at 60°C for 3h. Then add 600g of chlorpyrifos and 60g of imidacloprid, and at the same time add 3g of initiator benzoyl peroxide and 150mL of styrene, and react for 4h. After the reaction is completed and cooled, add 2.5 g of stabilizer succinic acid, 3.5 g of polymerization inhibitor p-benzoquinone, and add 30 mL of antifreeze ethylene glycol at the same time, and pour it into a container to obtain the required organic solvent-free chlorpyrifos emulsion in water (Chlorpyrifos imidacloprid aqueous emulsion product).

Embodiment 3

[0030] Add 80g of polyoxyethylene lauryl ether (emulsifier) into the reaction kettle, then add 1300mL of tap water, stir to make it react and dissolve, add 12.5g of azobisisobutyronitrile as a polymerization initiator, stir well and then add 900mL of methyl Methyl acrylate was reacted at 60°C for 3h. Then add 600g chlorpyrifos former medicine (add initiator azobisisobutyronitrile 3g, methyl methacrylate 150mL simultaneously, react 4h. After reaction finishes cooling, add stabilizer succinic acid 2.5g, polymerization inhibitor p-benzoquinone 2.5 g, add the antifreezing agent ethylene glycol of 30mL simultaneously, it is poured into the container and promptly obtains the required chlorpyrifos aqueous emulsion (product) that obtains without organic solvent.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap