Tight Gas Stimulation by In-Situ Nitrogen Generation

a nitrogen generation and gas well technology, applied in the direction of fluid removal, insulation, borehole/well accessories, etc., can solve the problems of inability to locate or predict when and where sweet spots, inability to search for and recover oil, and inability to achieve economic benefits, so as to prevent reaction and increase the rate of hydrocarbon production. effect of formation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020]Although the following detailed description contains many specific details for purposes of illustration, it is understood that one of ordinary skill in the art will appreciate that many examples, variations and alterations to the following details are within the scope and spirit of the invention. Accordingly, the exemplary embodiments of the invention described herein and provided in the appended figures are set forth without any loss of generality, and without imposing limitations, on the claimed invention.

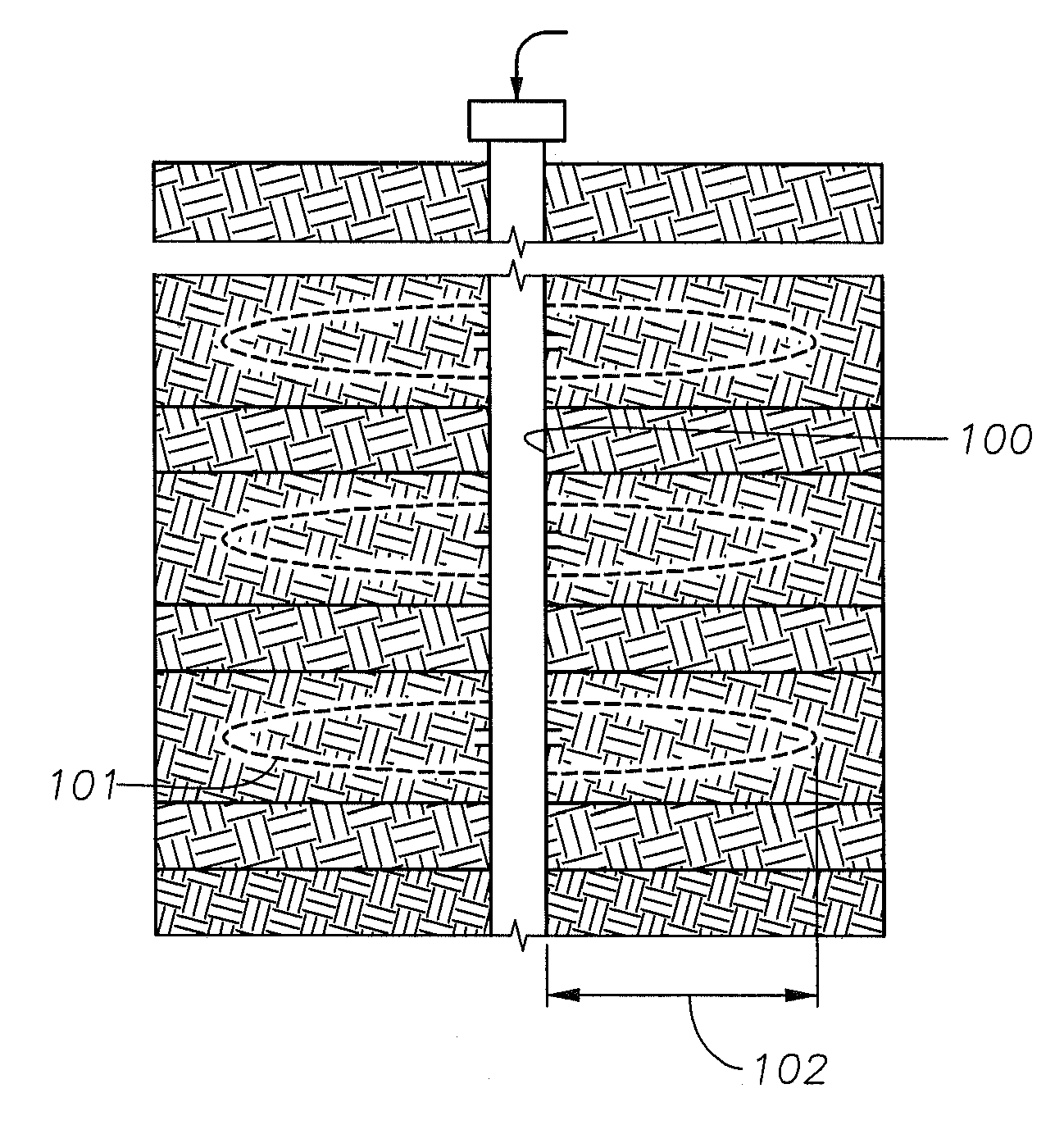

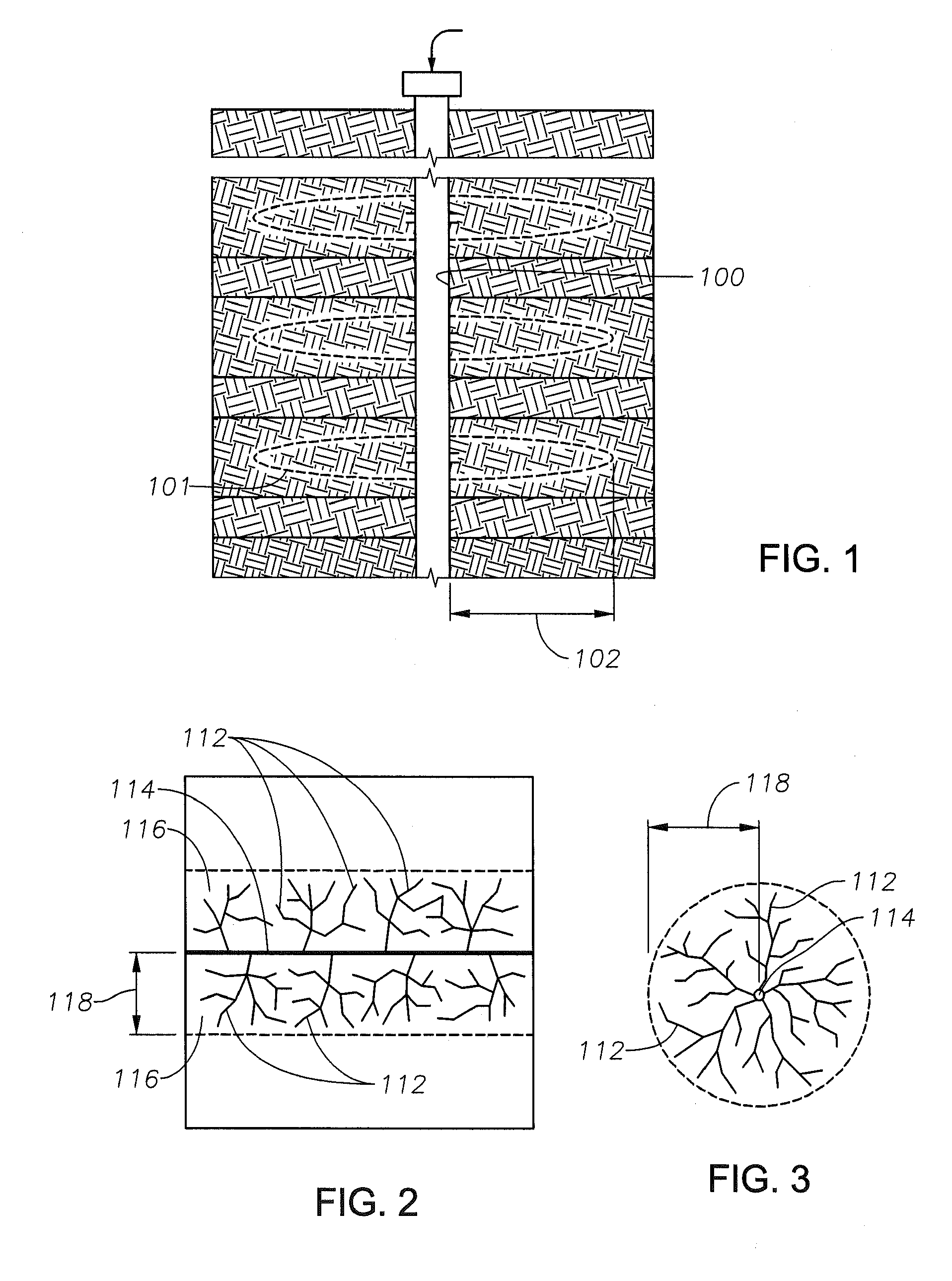

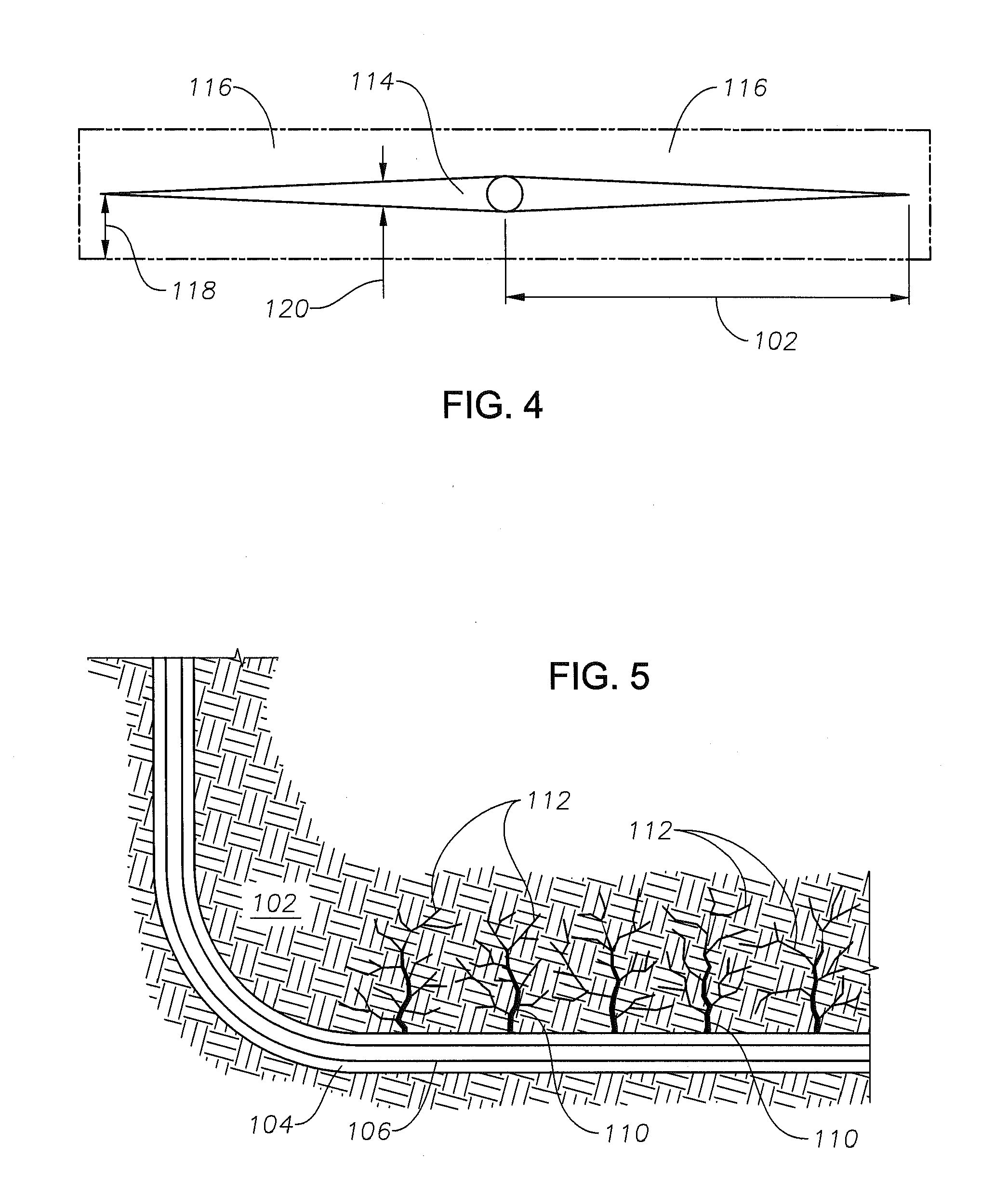

[0021]The methods described herein are directed to the generation of sweet spots at or near an fracture induced during a hydraulic fracturing procedure. When the present technique is utilized during hydraulic fracturing treatments, a synthetic sweet spot can be created, thereby stimulating production and enabling maximum enhancement of gas production. The technology and the techniques described herein thus can greatly increase the chances of recovering gases from low permea...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com