Burner and method for partially oxidizing liquid, carbon-containing fuel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

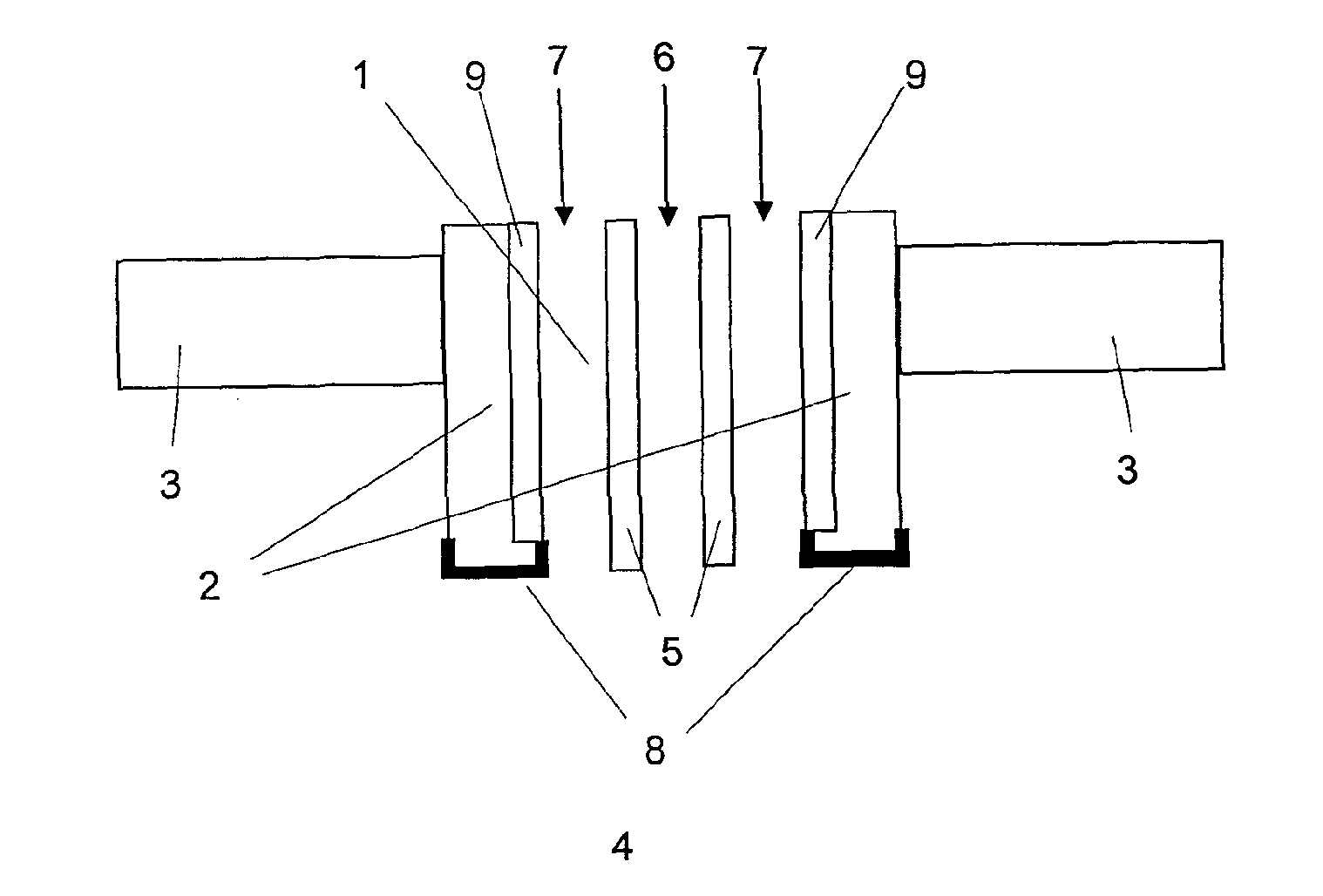

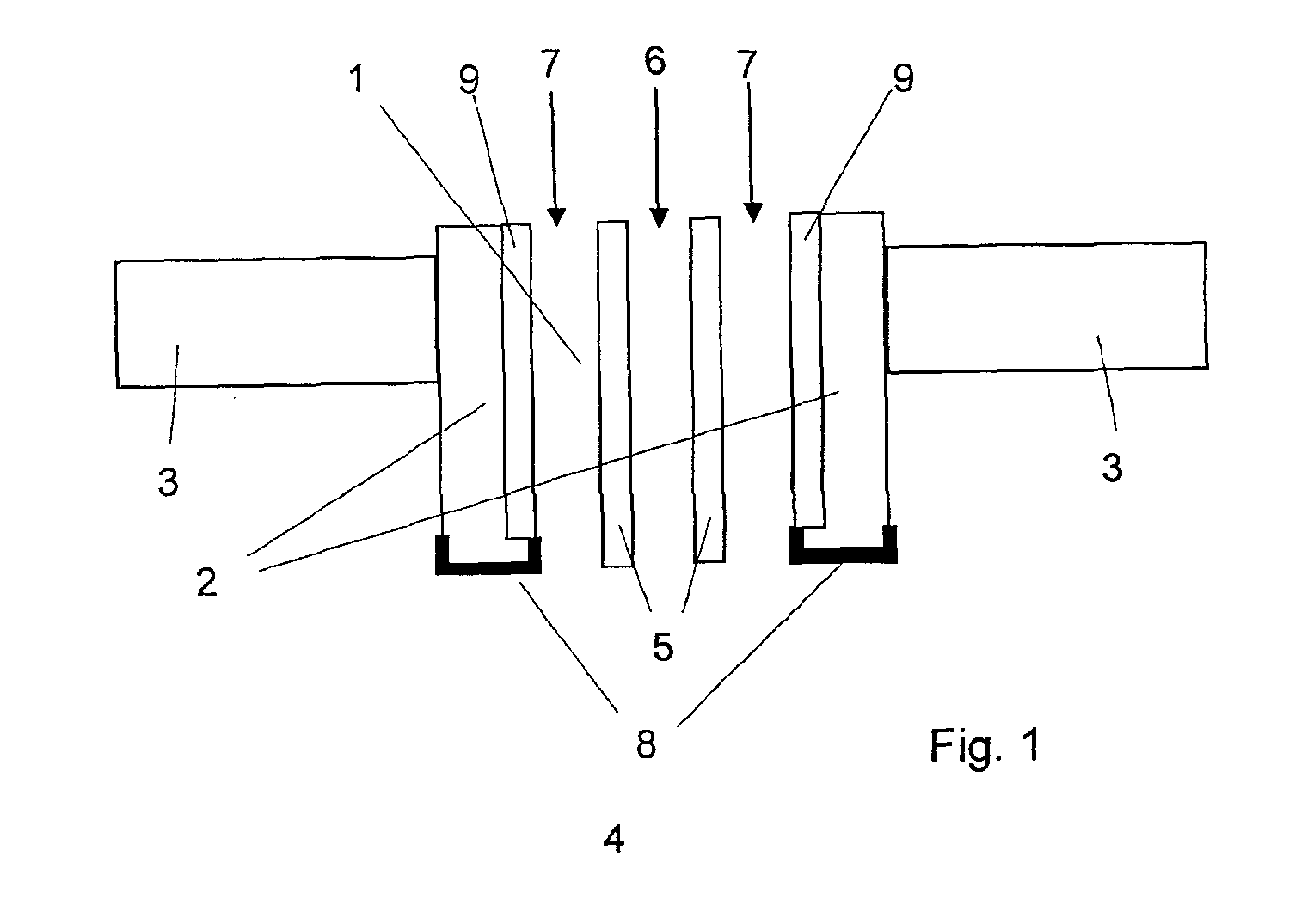

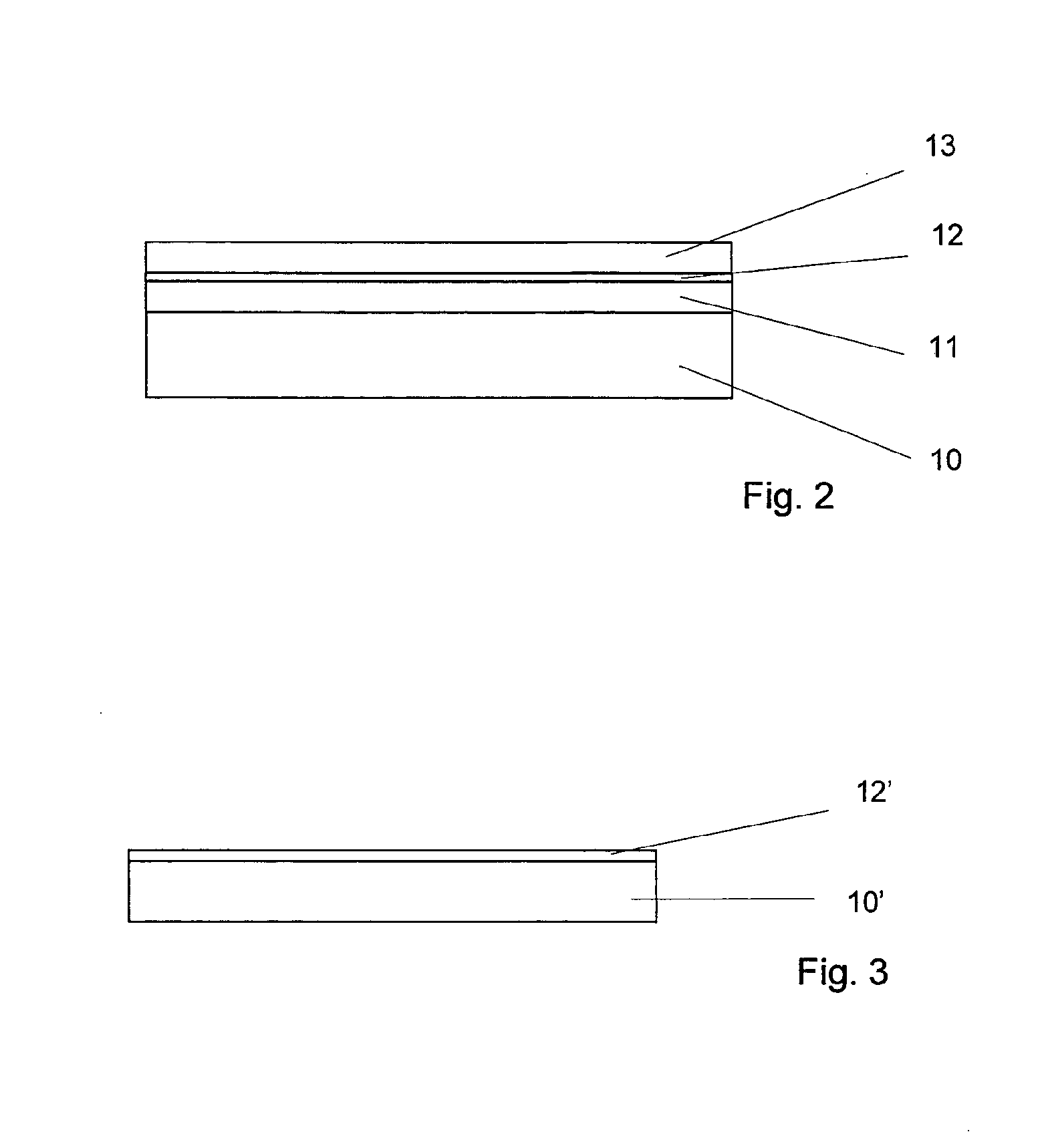

Embodiment Construction

[0011]Therefore, it has been the object to find a solution for extending the service life of the burner, which rather does not intervene in the construction of the burner and can be carried out economically.

[0012]The solution of the object according to the invention substantially can be derived from the characterizing features of claim 1 in conjunction with the features of the generic part. Further advantageous aspects of the invention can be taken from the sub-claims. This invention also relates to a process for the partial oxidation of liquid, carbonaceous fuel with steam and an oxygen-containing gas, in which the burner according to the invention is used.

[0013]This object is solved in that the parts of the outlet orifice directed towards the combustion chamber are wholly or partly provided with a coating or with a diffusion layer for protection against thermal load and / or corrosion.

[0014]This inventive solution of the object was induced by the proven practice in the construction ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com