Fluid control device

a control device and fluid technology, applied in the direction of positive displacement liquid engines, valve operating means/release devices, machines/engines, etc., can solve the problem of excessive load on the motor, and achieve the effect of simple configuration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031]An embodiment will be described below with reference to the drawings. In this embodiment, the present invention is realized as a flow rate adjustment device that adjusts a flow rate of a fluid in a semiconductor manufacturing apparatus or the like.

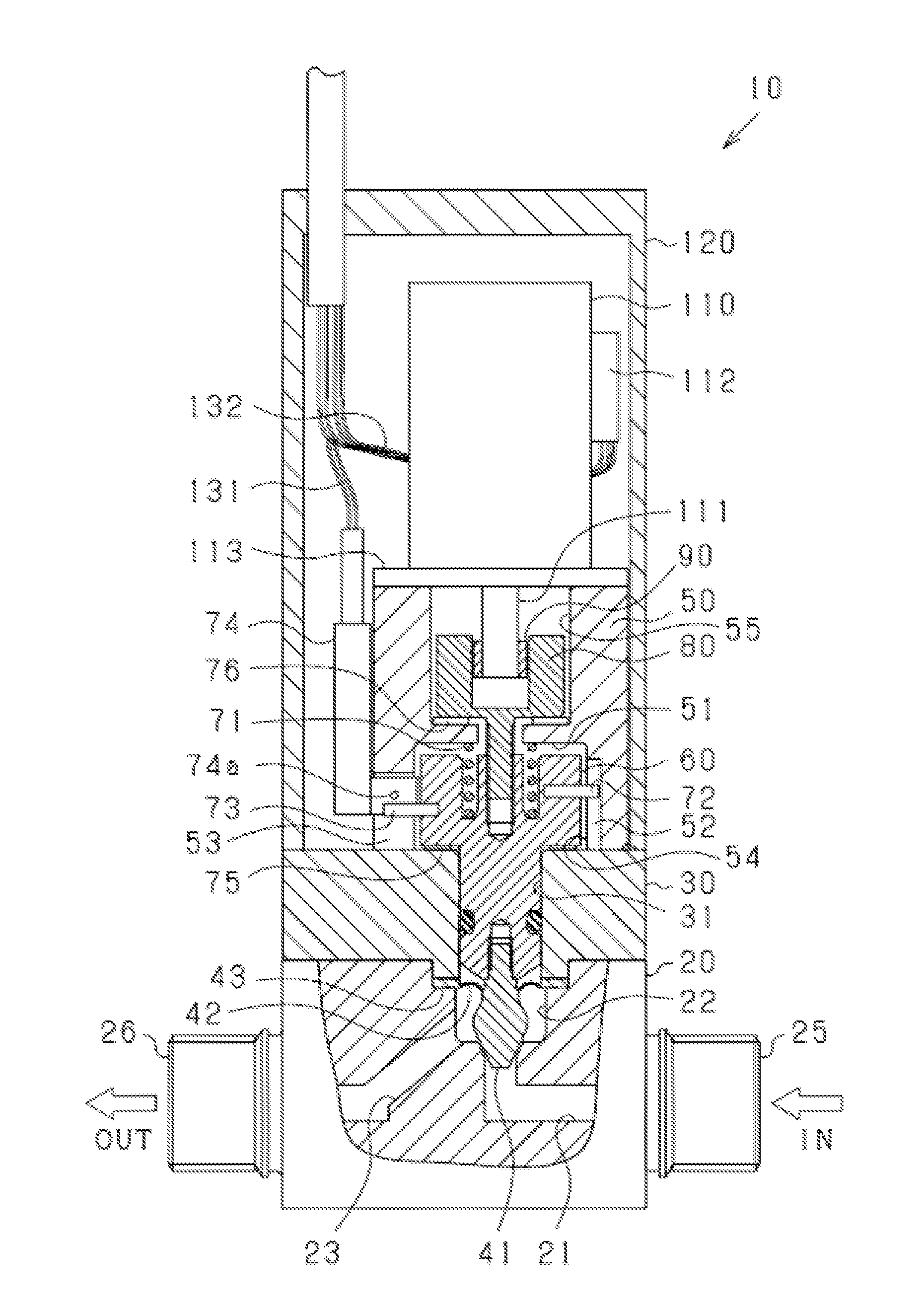

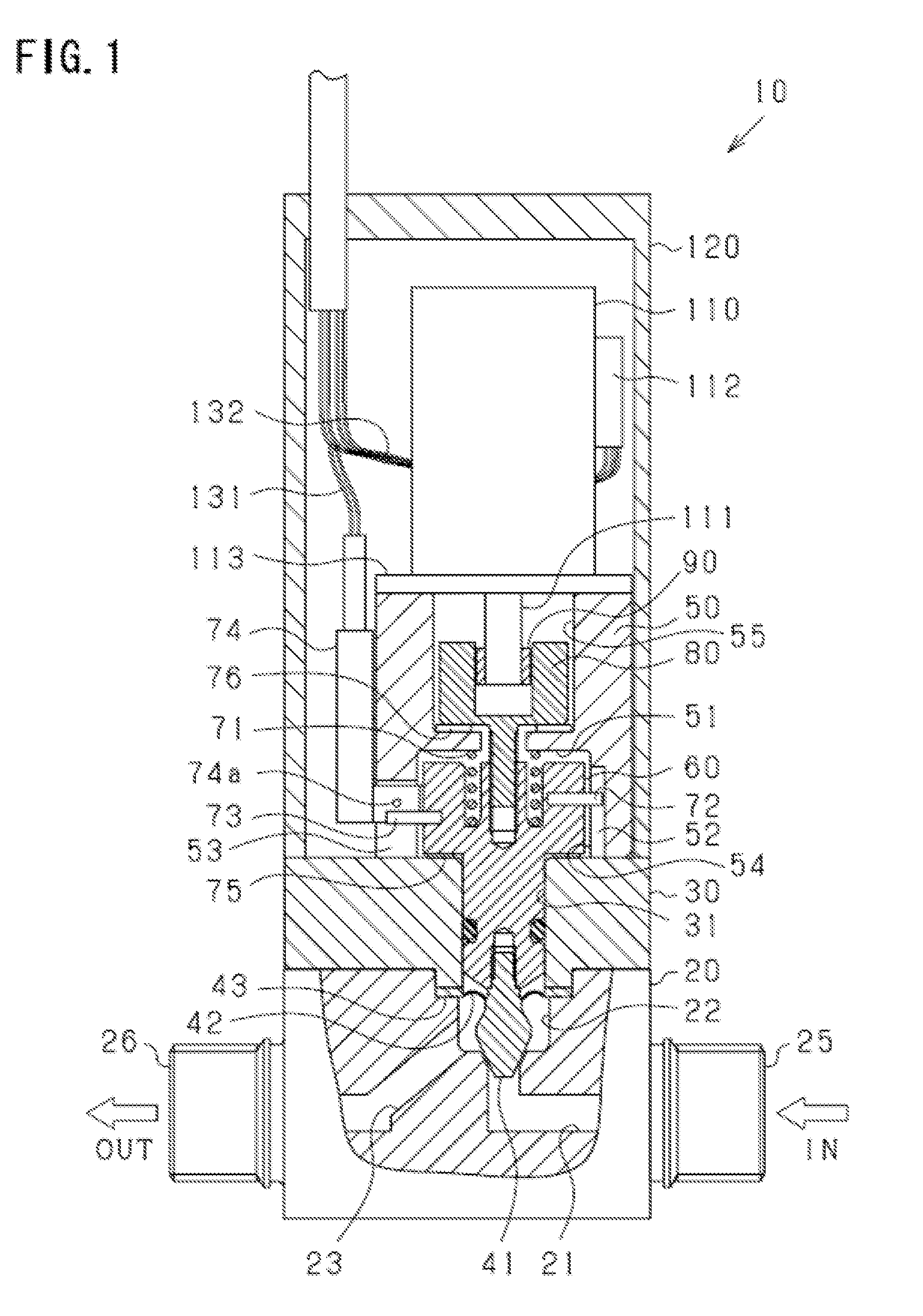

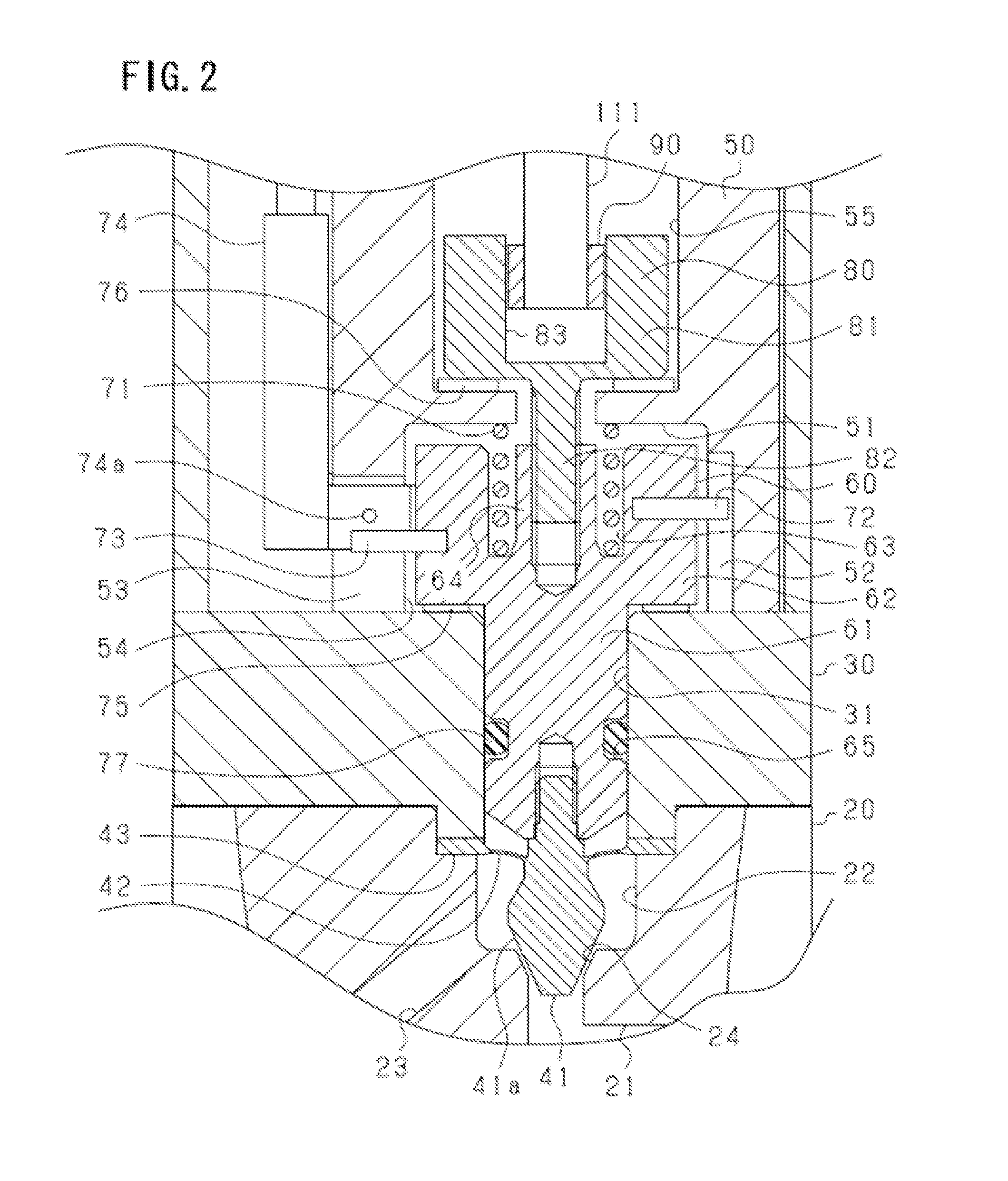

[0032]FIG. 1 is a partial sectional view showing a flow rate adjustment device 10. The flow rate adjustment device 10 (fluid control device) includes a valve main body 20, a first cylinder 30, a second cylinder 50, a motor 110, and a housing 120.

[0033]The valve main body 20 is provided with an inflow port 25 through which a fluid (a liquid) flows in, and an outflow port 26 through which the fluid flows out. The valve main body 20 is formed of a chemical-resistant fluorine resin, for example PTFE (Poly Tetra Fluoro Ethylene). A flow passage 21 connected to the inflow port 25, a flow passage 23 connected to the outflow port 26, and a valve chamber 22 that connects the flow passages 21 and 23 are formed in an interior of the valve main ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com