Apparatus for making, handling, and filling pouches

a pouch and pouch technology, applied in the field of pouches for making, handling, and filling pouches, can solve the problems of high price, complex structure, and high cost of all such equipment, and achieve the effects of easy maintenance and operation, high price, and high pri

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

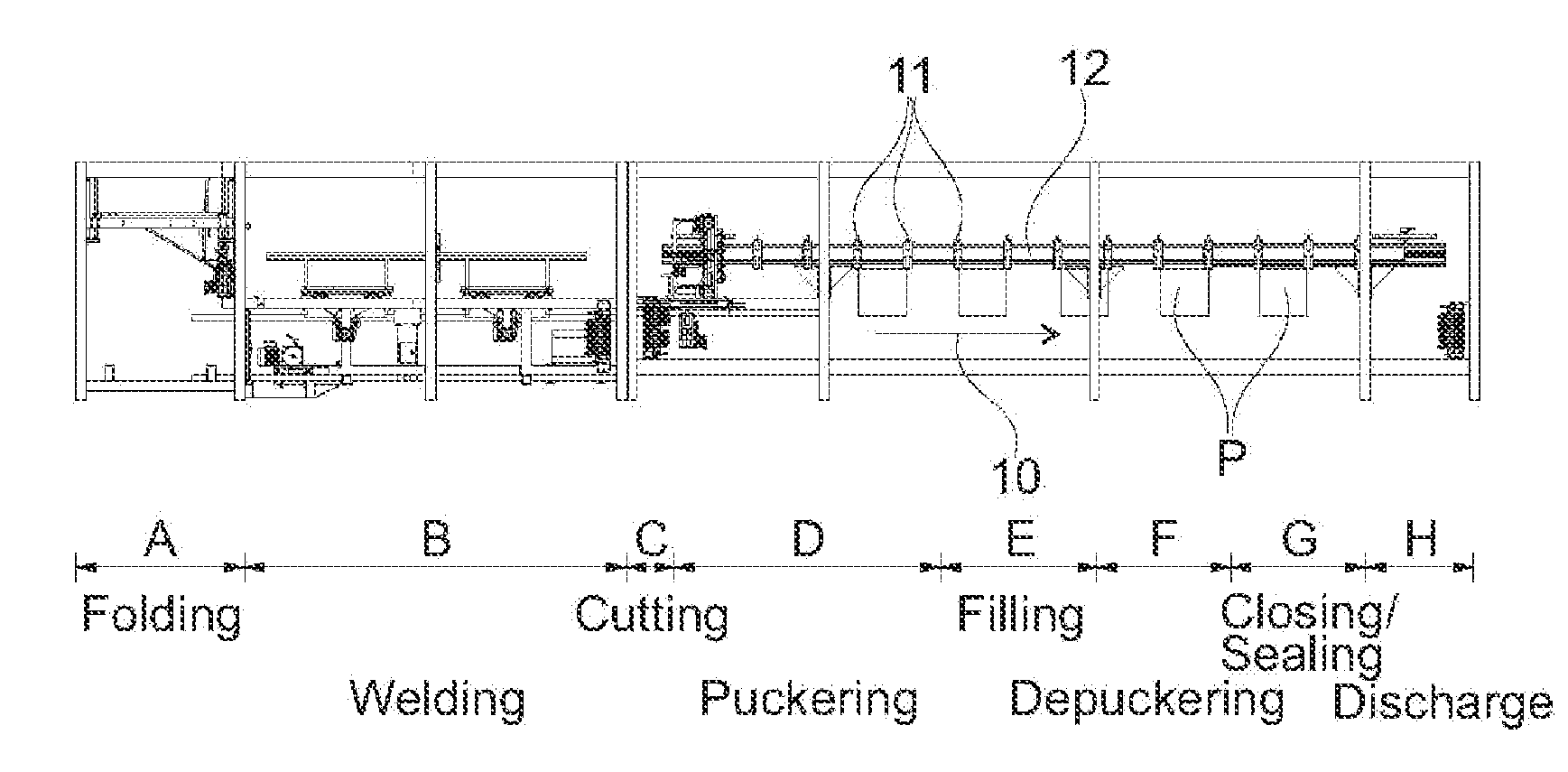

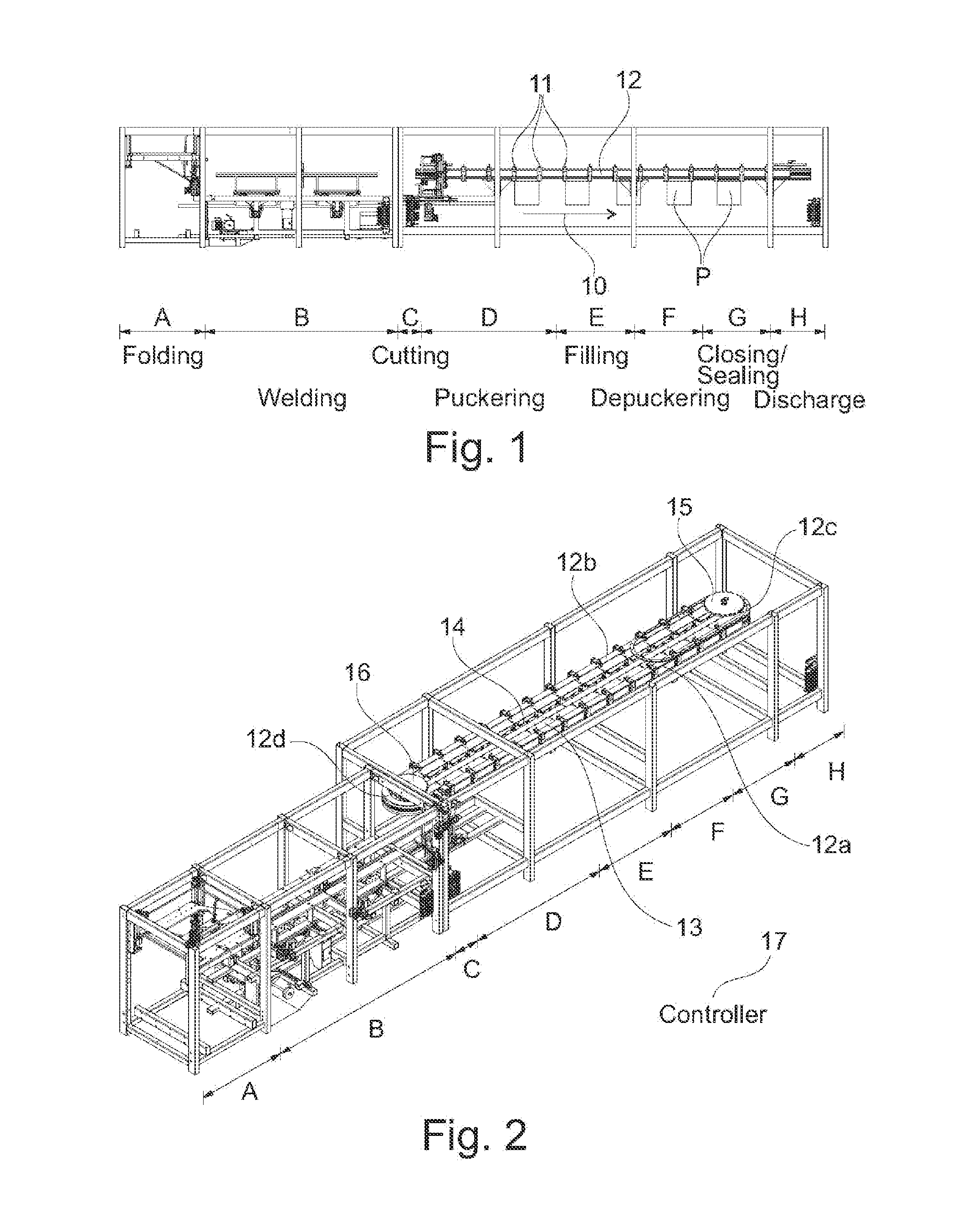

[0032]As seen in FIGS. 1 and 2 a machine according to the invention extends in a longitudinal travel direction 10 and has a folding station A, a welding station B, and a cutting station C as described in US 2010 / 0255372, whose disclosure is herewith incorporated by reference, together forming an intake station in which a sheet of plastic film is folded in half, then given a series of transversely throughgoing welds, and then cut into individual pouches P between the welds as is well known in the art. The individual pouches P are then oriented with their mouths directed upward and are each gripped between two longitudinally spaced carriage clamps 11 on a track 12 to proceed downstream in the direction 10.

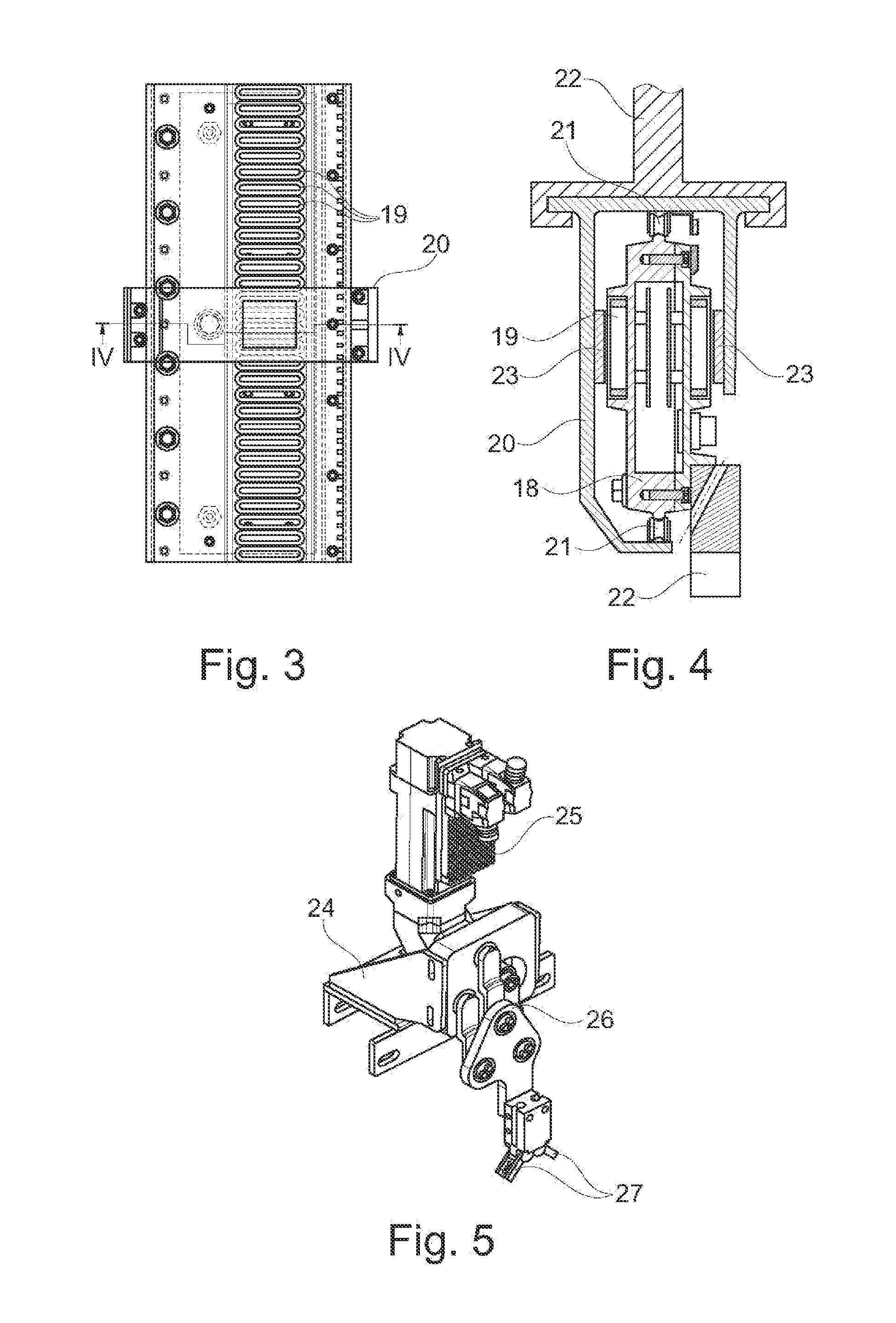

[0033]As also indicated in FIGS. 7 and 8, in the puckering station D the trailing clamp 11 of each pair of pouch-suspending clamps 11 is accelerated slightly or the leading clamp 11 is decelerated, or both, so that the clamps 11 of each pair get closer together. At the same time unil...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Speed | aaaaa | aaaaa |

| Transport properties | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com