Salad Bar Cooler

a cooling system and salad bar technology, applied in the field of refrigeration systems, can solve the problems of adding noise and motor vibration, kritzer failing to disclose the means of artfully configuring cooling units, and gaetke being poorly suited for permanent salad bars,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

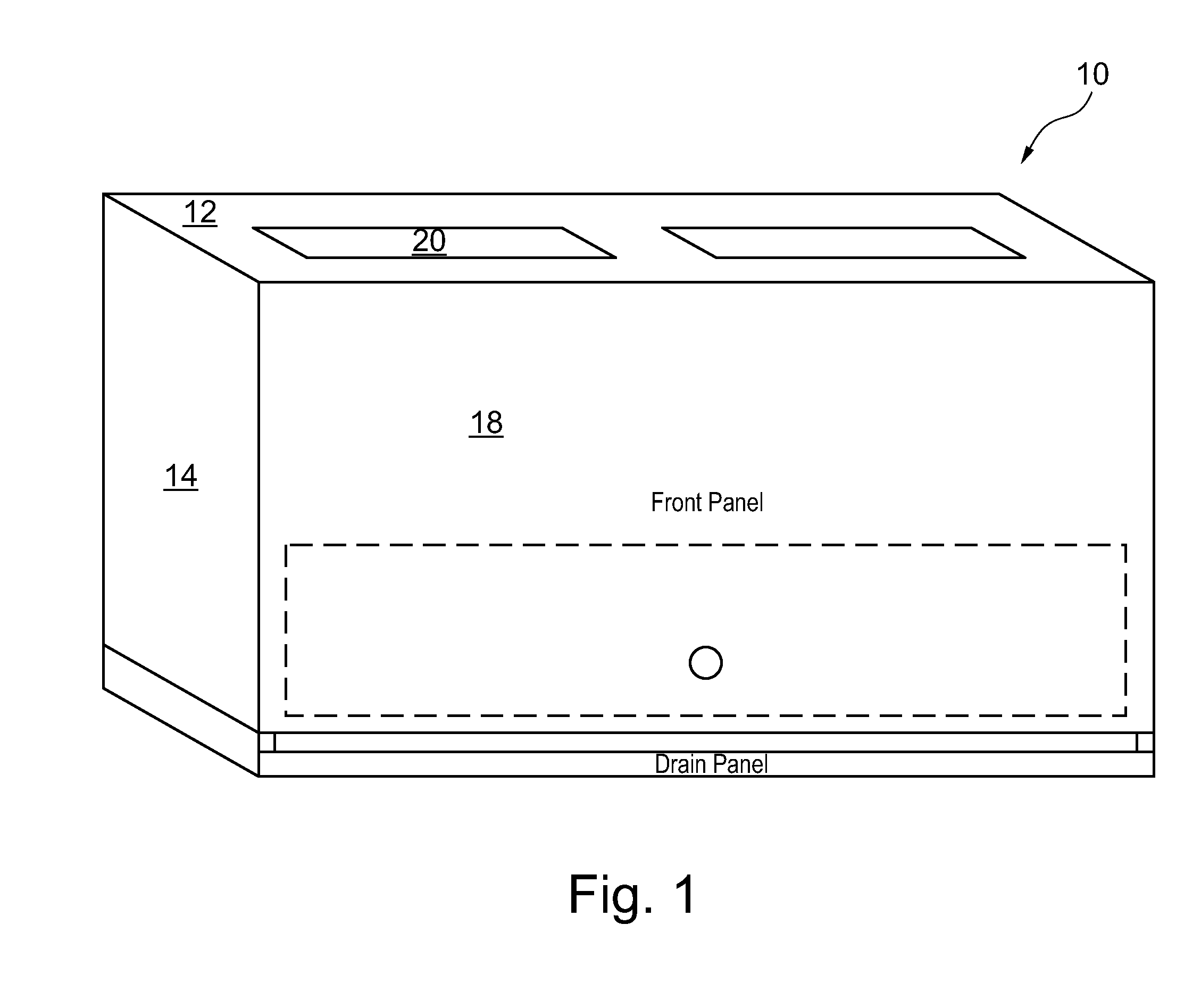

first embodiment

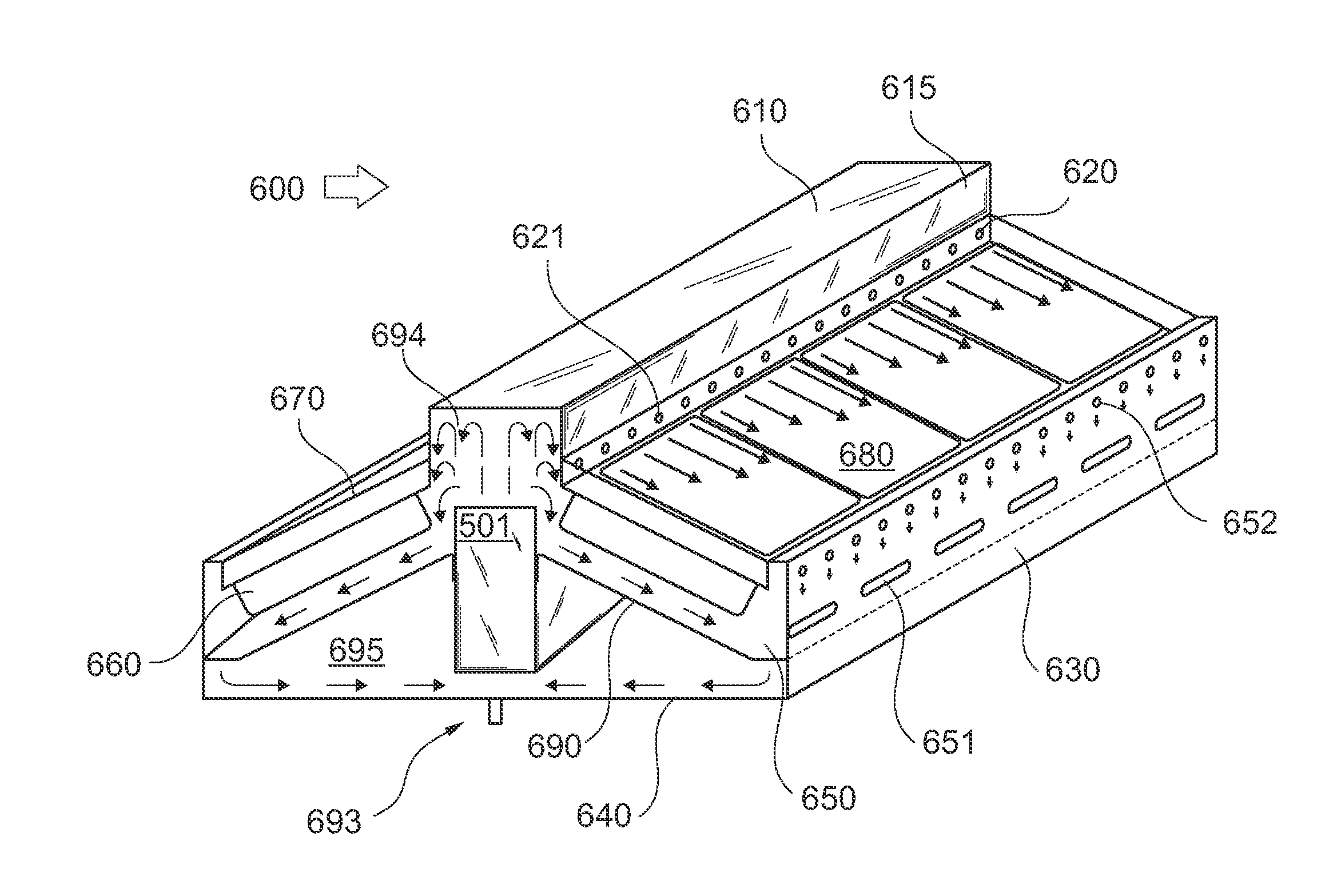

[0131]FIGS. 11 to 16 depict various parts and aspects of a

second embodiment

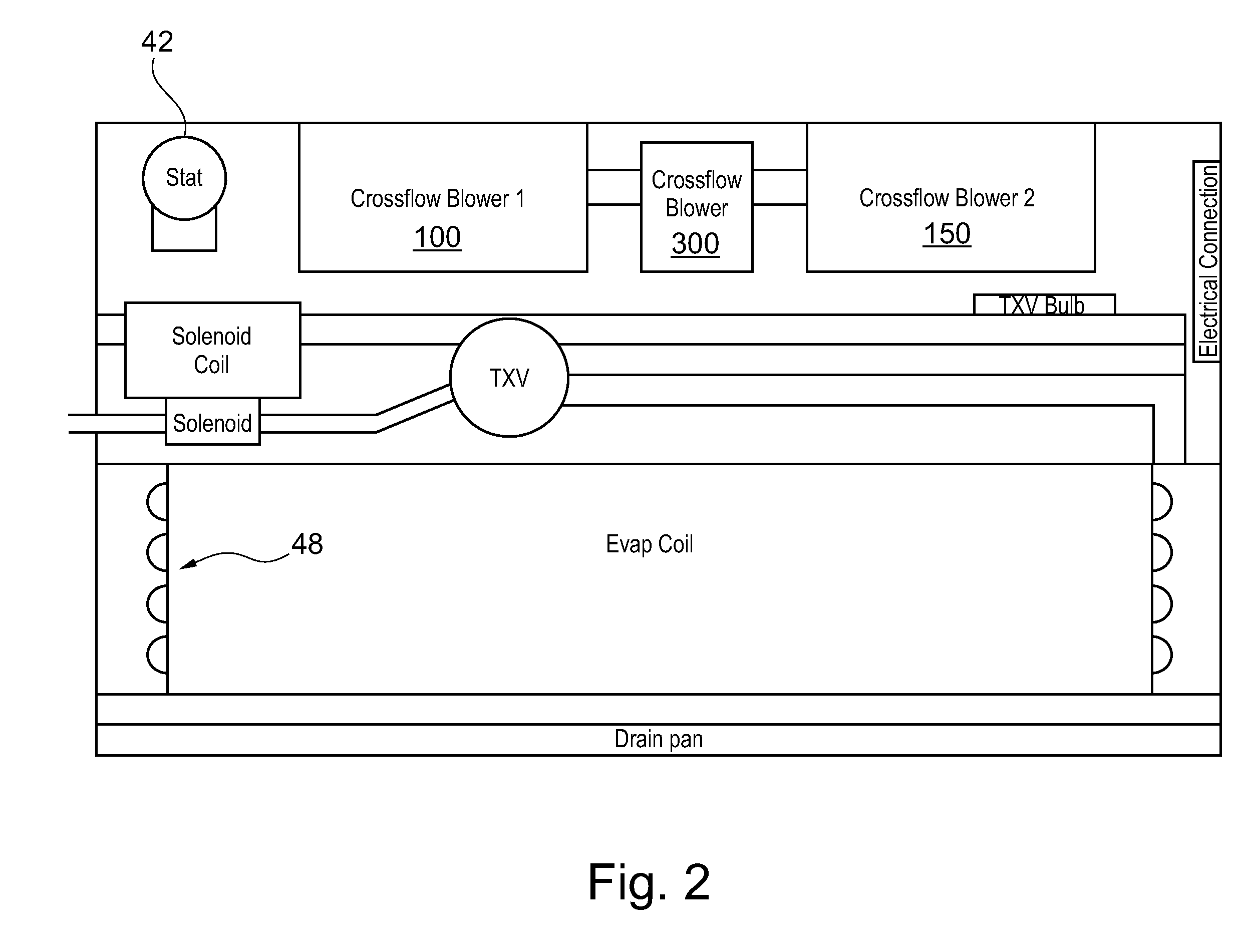

[0132]FIG. 17 depicts a second embodiment comprising a top plate 510, a condensation pan 500, a motor 515, a liquid line u bend 520, a TXV valve 525 one or more cross-flow blower wheels 530, a coated evaporator coil 535 and a sensing bulb 540.

[0133]FIG. 18 depicts a lower housing 544, motor housing 551, the motor housing shown with a back plate 570, top plate 550 of motor housing and discharge vents 555 for top discharge. FIG. 18 also depicts a front discharge plate cover 545 having discharge vents 546 for side discharge. A digital control stat 560 is shown fastened to the front discharge plate cover 545.

[0134]FIG. 19 depicts a second embodiment in general 501. In the foreground a top plate 550 of the motor housing is shown with discharge vents 555 for top discharge of cooled air. The top plate 550 of the motor housing also has a plurality of fastener voids sometimes used to secure fastening clips on the fan and motor unit. In the background, FIG. 19 depicts a front discharge plate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com