Heat dissipation assembly

a technology of heat dissipation assembly and heat sink, which is applied in the direction of lighting, heating apparatus, and semiconductor/solid-state device details. it can solve the problems of reducing the heat dissipation efficiency of the heat sink, and the heat generated by the central processing unit (cpus) of the computer or server

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010]The present disclosure, including the accompanying drawings, is illustrated by way of examples and not by way of limitation. It should be noted that references to “an” or “one” embodiment in this disclosure are not necessarily to the same embodiment, and such references mean at least one.

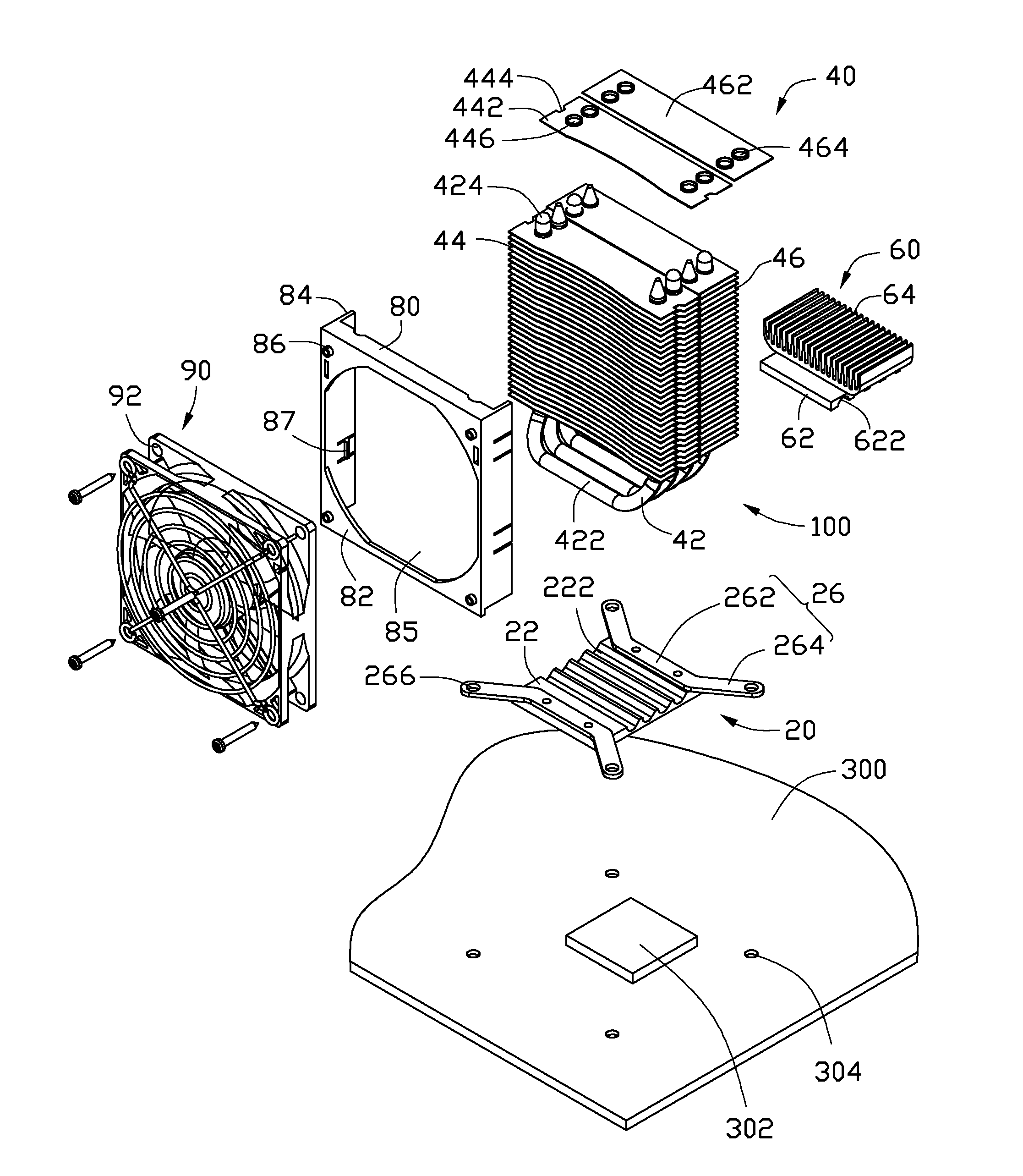

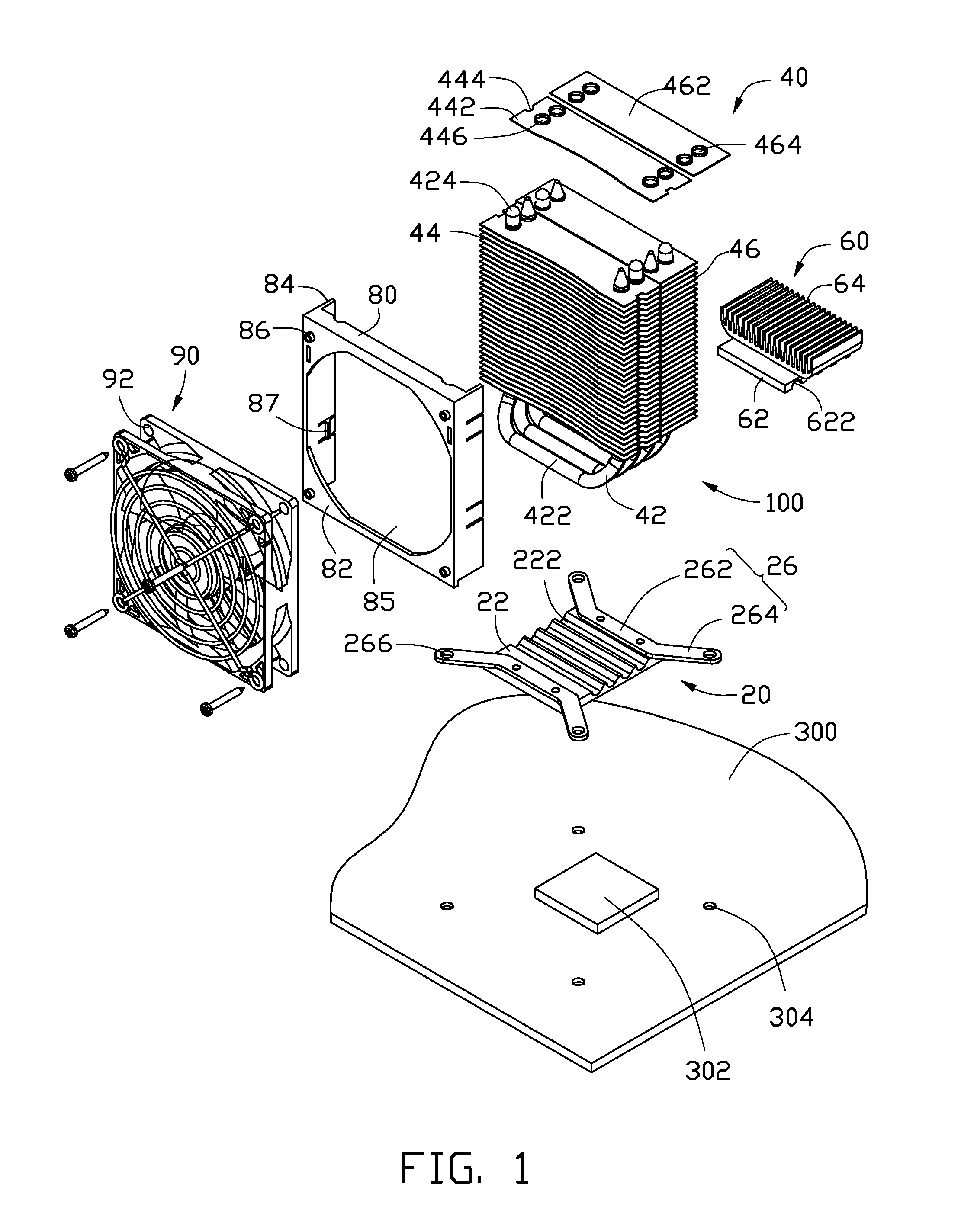

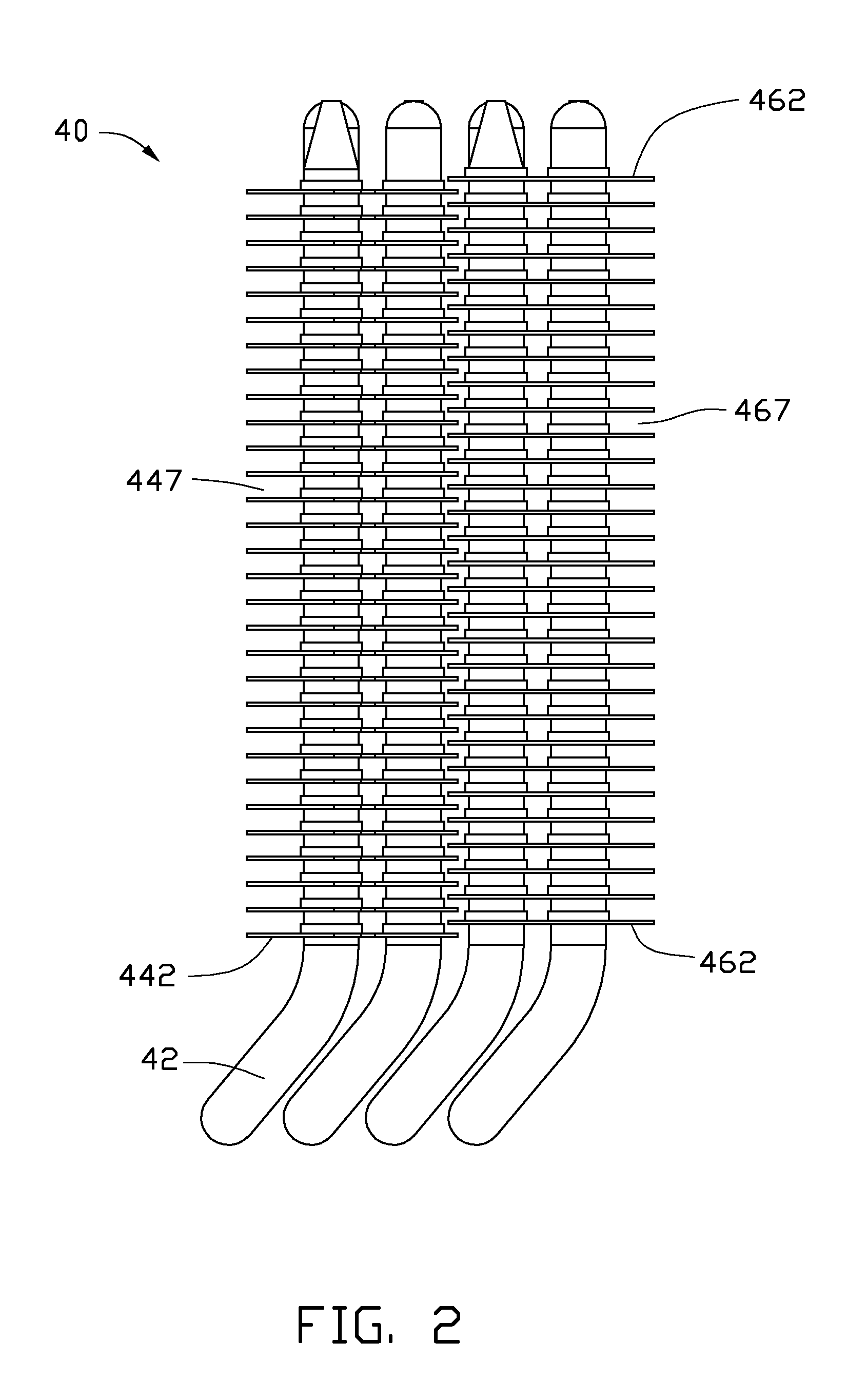

[0011]Referring to FIG. 1, an embodiment of a heat dissipation assembly 100 for dissipating heat of an electronic component 302 mounted on a motherboard 300 includes a base 20, a first heat sink 40, a second heat sink 60, a bracket 80, and a fan 90. The motherboard 300 defines four fastening holes 304 adjacent to four corners of the electronic component 302. In the embodiment, the electronic component 302 is a central processing unit.

[0012]The base 20 includes a bottom wall 22 and two substantially U-shaped fixing plates 26 fixed to two opposite ends of the bottom wall 22. The bottom wall 22 defines four receiving slots 222 parallel to the ends of the bottom wall 22, between the fixing plates ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com