Thermal Management Structures for Battery Packs

a technology of battery packs and management structures, applied in the direction of cell components, electrochemical generators, cell component details, etc., can solve the problems of premature cell degradation and failure, thermal management problems, and compounding problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

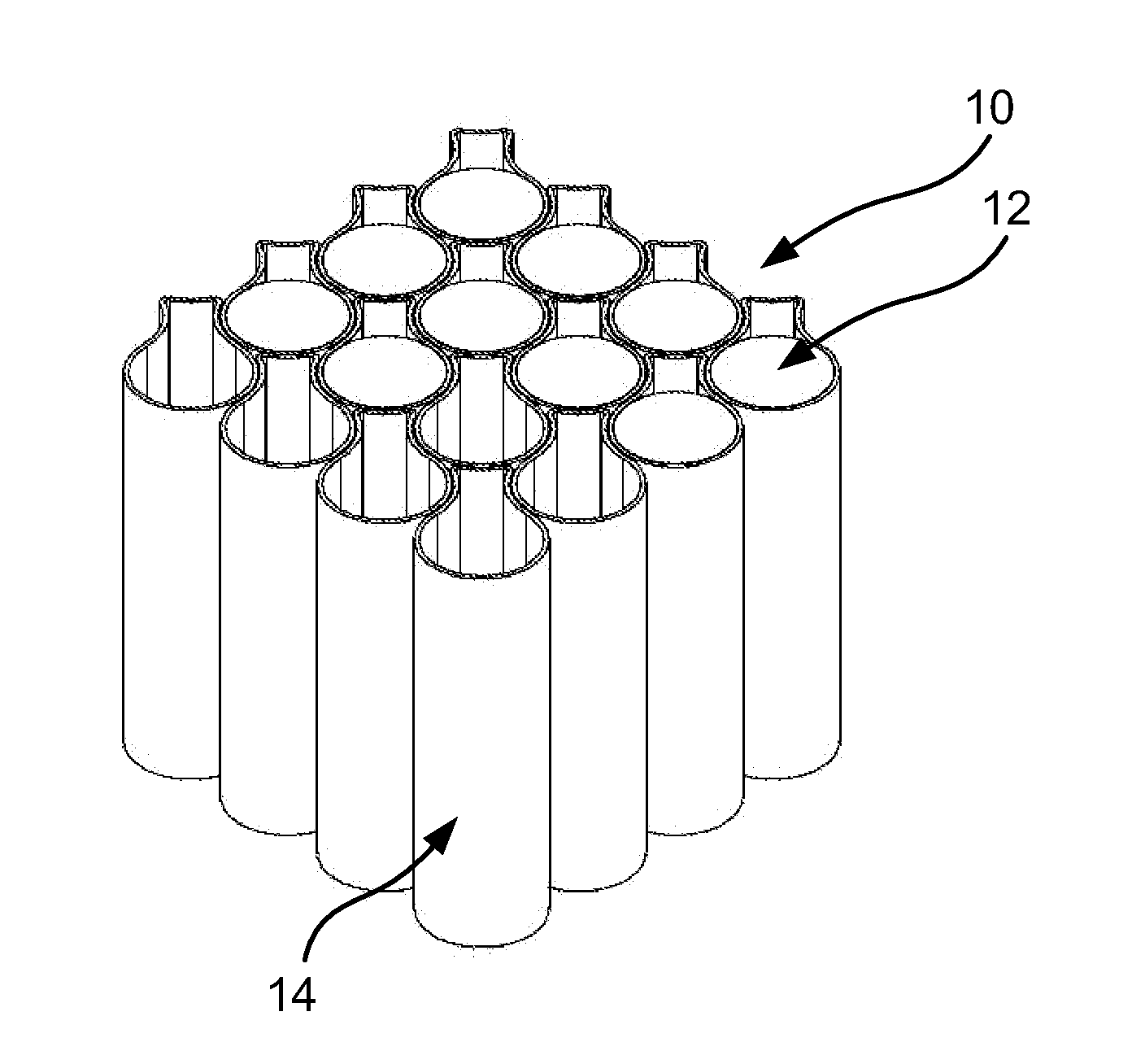

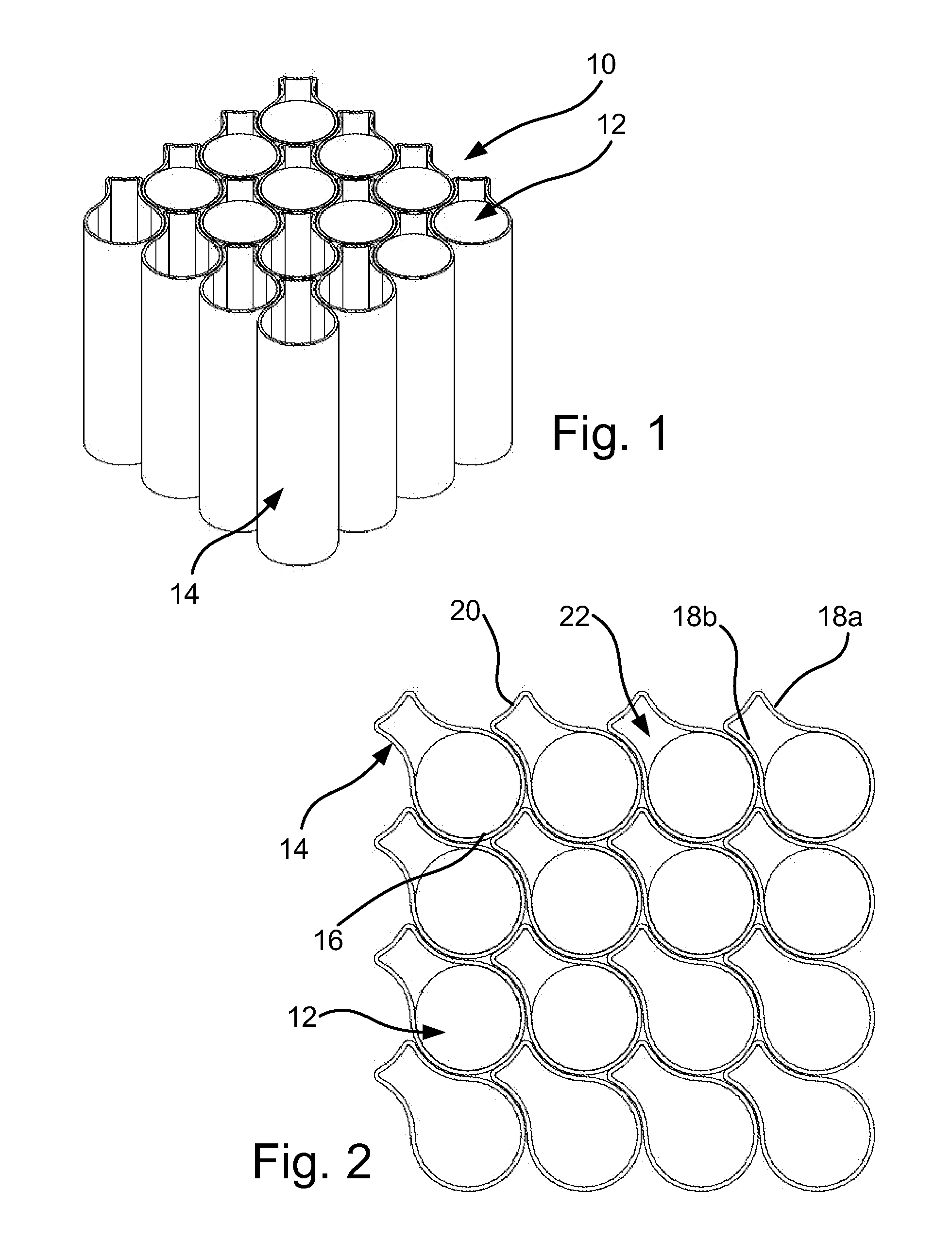

[0042]With reference now to FIGS. 1 and 2, a battery pack is shown and generally indicated by the numeral 10. Battery pack 10 includes a plurality of cylindrical battery cells 12 arranged in aligned rows. A heat spreader 14 made of graphite sheet material is wrapped around each battery cell in a manner which, as will be described below in greater detail, improves thermal performance. In one embodiment, the heat spreader 14 is generally tubular and extends longitudinally substantially the entire longitudinal length of the battery cell 12. In other embodiments, the heat spreader 14 is longer than the battery cell 12 so that a portion extends beyond battery cell 12 at one or both ends.

[0043]In cross-section, heat spreader 14 is generally piscine shaped, having a substantially semi-circular portion 16 with a diameter sized so that the interior surface of portion 16 is substantially flush with, and in thermal contact with, the radial outer surface of battery cell 12. A pair of curved leg...

second embodiment

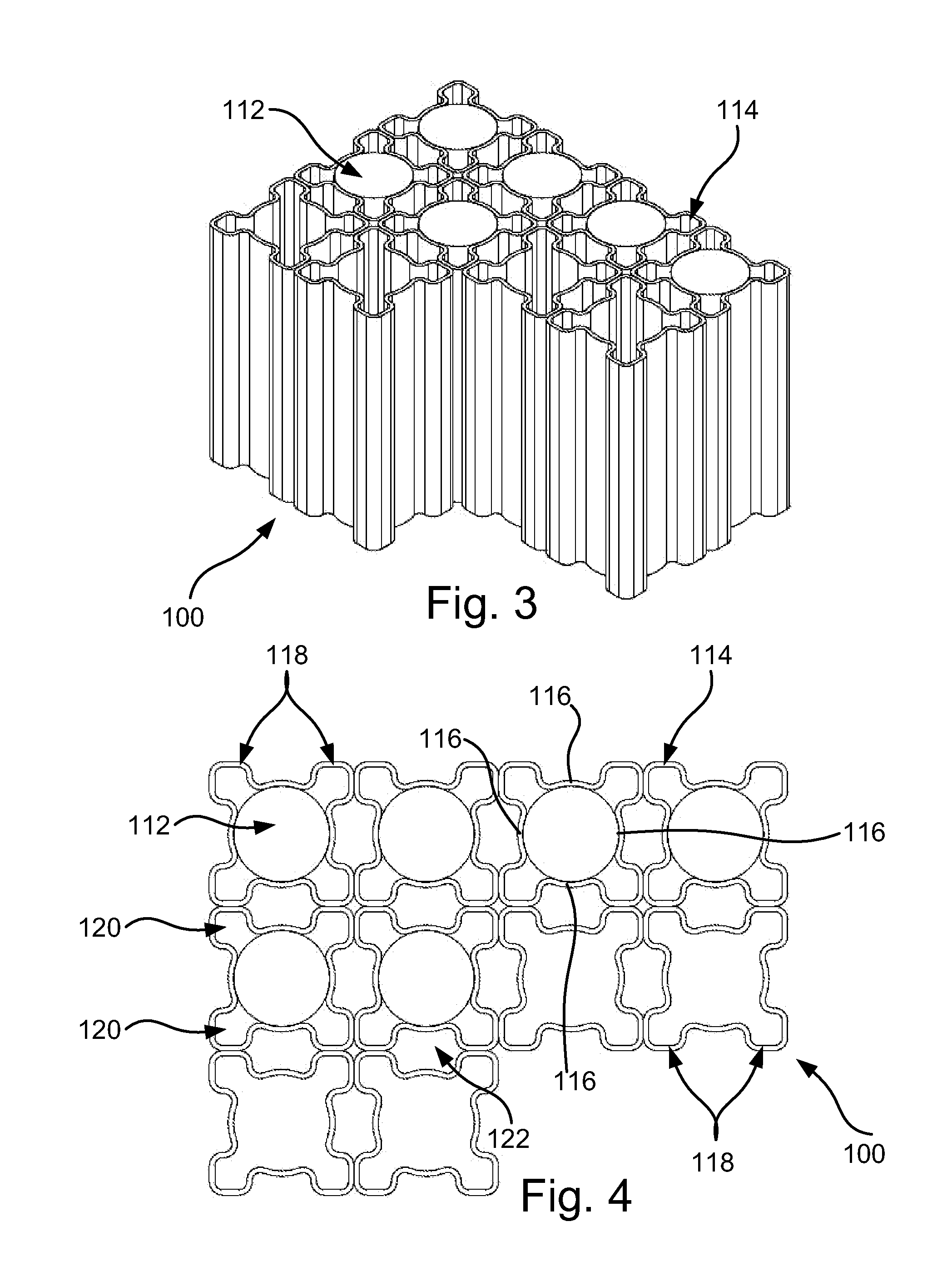

[0045]With referenced now to FIGS. 3 and 4, a battery pack is shown and generally indicated by the numeral 100. Battery pack 100 includes a plurality of cylindrical battery cells 112 arranged in aligned rows. Each row may have any number of cells 112, and likewise, any number of rows may be employed. A heat spreader 114 made of graphite sheet material or extruded graphite is positioned around each battery cell 112 in a manner which, as will be described below in greater detail, improves thermal performance. In one embodiment, the heat spreader 114 is generally tubular and extends substantially the entire longitudinal length of the battery cell 112. In other embodiments, the heat spreader 114 is longer than the battery cell 112 so that it extends beyond battery cell 112 at one or both ends.

[0046]In cross-section, each heat spreader 114 includes is generally cruciform shaped, having four equidistant arced sections 116. Arced sections 116 include a radius sized so that the interior sur...

third embodiment

[0047]With referenced now to FIGS. 5 and 6, a battery pack is shown and generally indicated by the numeral 210. Battery pack 210 includes a plurality of cylindrical battery cells 212 arranged in aligned rows. Each row may have any number of cells 212, and likewise, any number of rows may be employed. A heat spreader 214 is made of graphite sheet material or extruded graphite and is positioned around each battery cell 212 in a manner which, as will be described below in greater detail, improves thermal performance. In one embodiment, the heat spreader 214 is generally tubular and extends substantially the entire longitudinal length of the battery cell 212. In other embodiments, the heat spreader 214 is longer than the battery cell 212 so that it extends beyond battery cell 212 at one or both ends.

[0048]In cross-section each heat spreader 214 includes a square outer wall 216. As can be seen in FIG. 6, a portion of the square outer wall 216 of each heat spreader 214 is arranged to be i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com