Floodgate

a floodgate and floodgate technology, applied in the field of floodgates, can solve the problems of pneumatic cylinders employing paper gaskets, which may also be damaged by condensate, and achieve the effect of fast setup time for floodgate systems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

second embodiment

[0065]FIG. 10(a) and (b) are views of a floodgate 100b which is a variation of the floodgate 100, and which is the invention. FIG. 10(a) illustrates the floodgate 100b when the floodgate 100b is activated, whereas FIG. 10(b) illustrates the floodgate 100b when the floodgate 100b is deactivated. The floodgate 100b has a construction very similar to the floodgate 100, so like elements are given the same reference numerals. In contrast to the floodgate 100, the floodgate 100b has a steel frame 503 supporting a steel plate 501, on which are formed a wire mesh 505 and a top layer 507 which may be concrete, tile or stone. The steel plate 501 and frame 503 give the floodgate 100b additional strength to support a vehicle passing over the floodgate 100b when the floodgate 100b is deactivated.

third embodiment

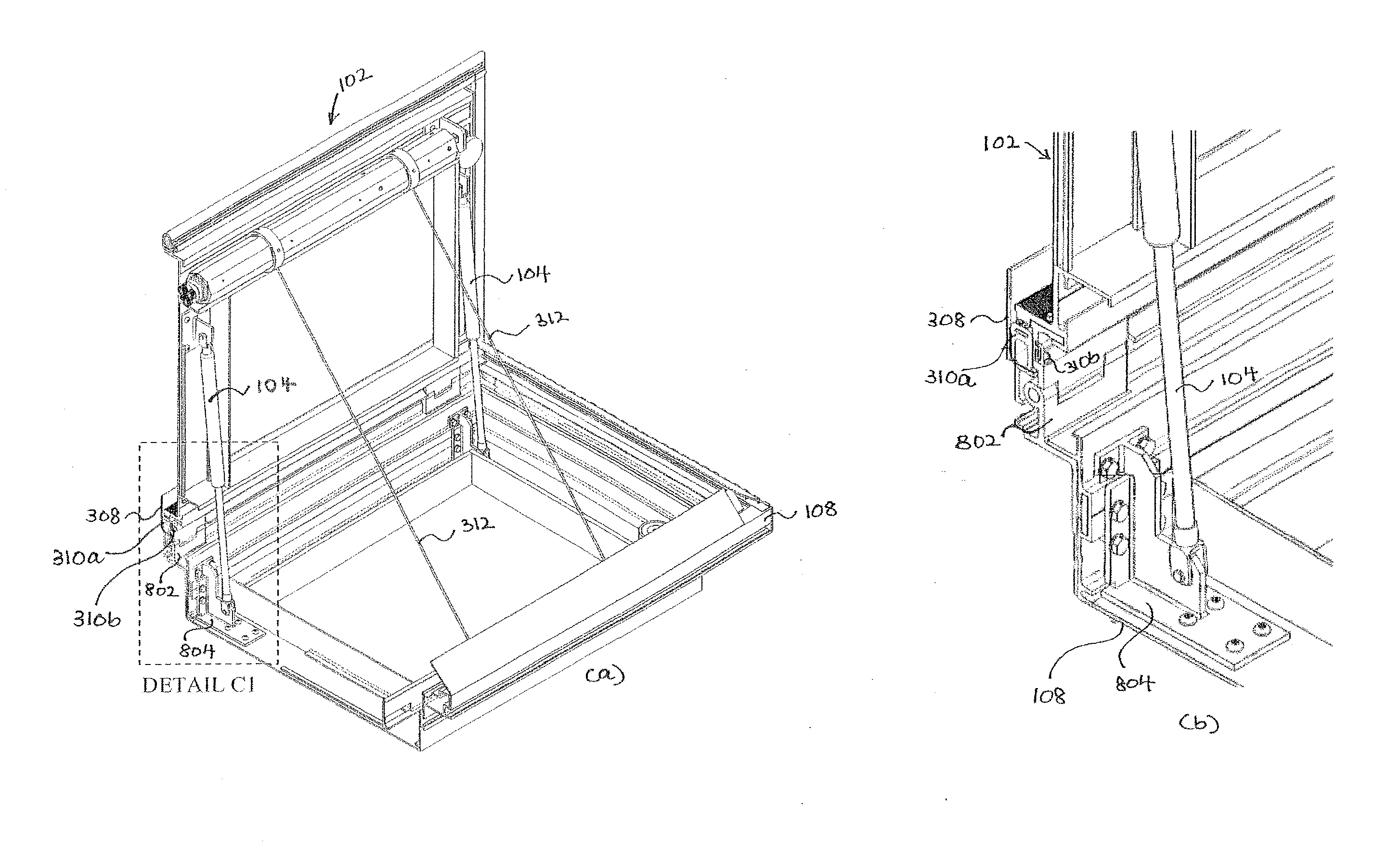

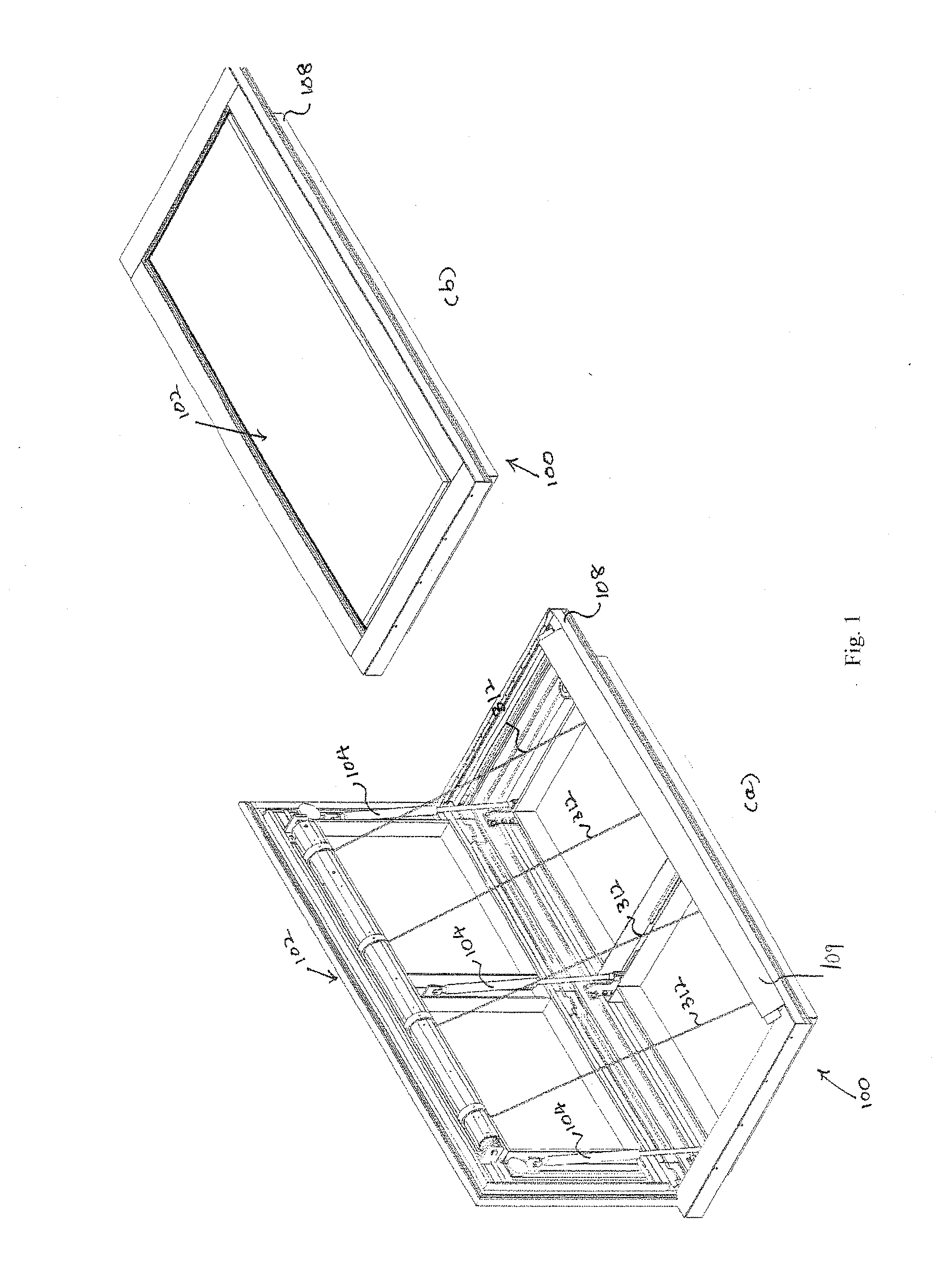

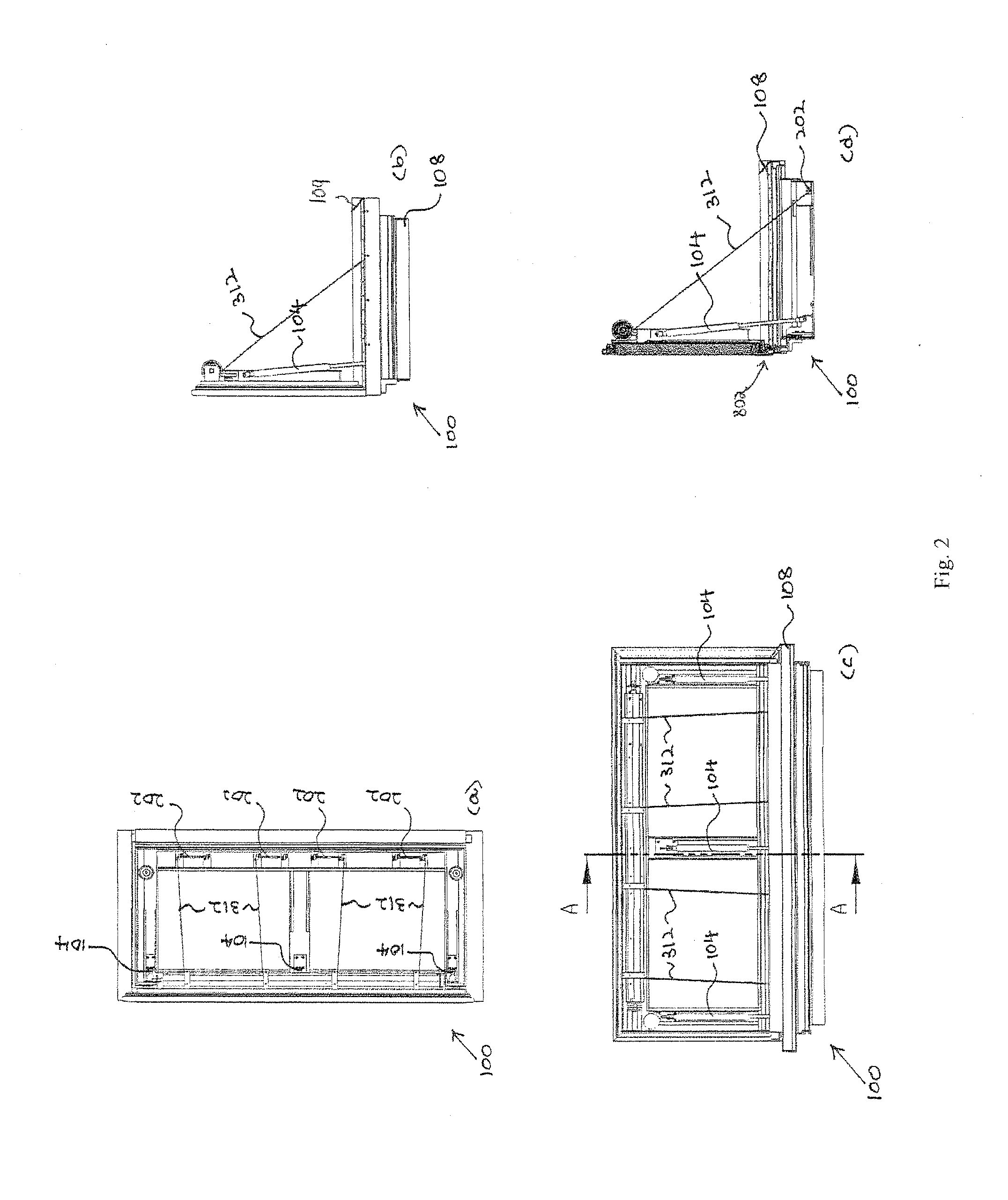

[0066]FIG. 11 illustrates perspective views of a floodgate 1000 which is another variation of the floodgate 100 and which is the invention. FIG. 11(a) illustrates the floodgate 1000 when the floodgate 1000 is activated whereas FIG. 11(b) illustrates the floodgate 1000 when the floodgate 1000 is deactivated. FIGS. 12 and 13 respectively illustrate a cross-sectional side view of the floodgate 1000 when the floodgate 1000 is deactivated and a cross-sectional side view of the floodgate 1000 when the floodgate 1000 is activated. The floodgate 1000 is similar to the floodgate 100 and thus, the same parts will have the same reference numerals with the addition of prime.

[0067]The floodgate 1000 works in the same manner as the floodgates 100, 100b. However, unlike the floodgates 100, 100b which comprise a plurality of tubular drives 202, each with an integrated locking member, the floodgate 1000 comprises a plurality of stand-alone locking members in the form of electromagnetic locks 1102 (s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com