Turbocharger, notably for a combustion engine

a technology of turbocharger and combustion engine, which is applied in the direction of machines/engines, rigid support of bearing units, liquid fuel engines, etc., can solve the problems of increasing mounting costs and indentations on the raceways of rolling bearings, and achieves the effect of simple manufacturing and economics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

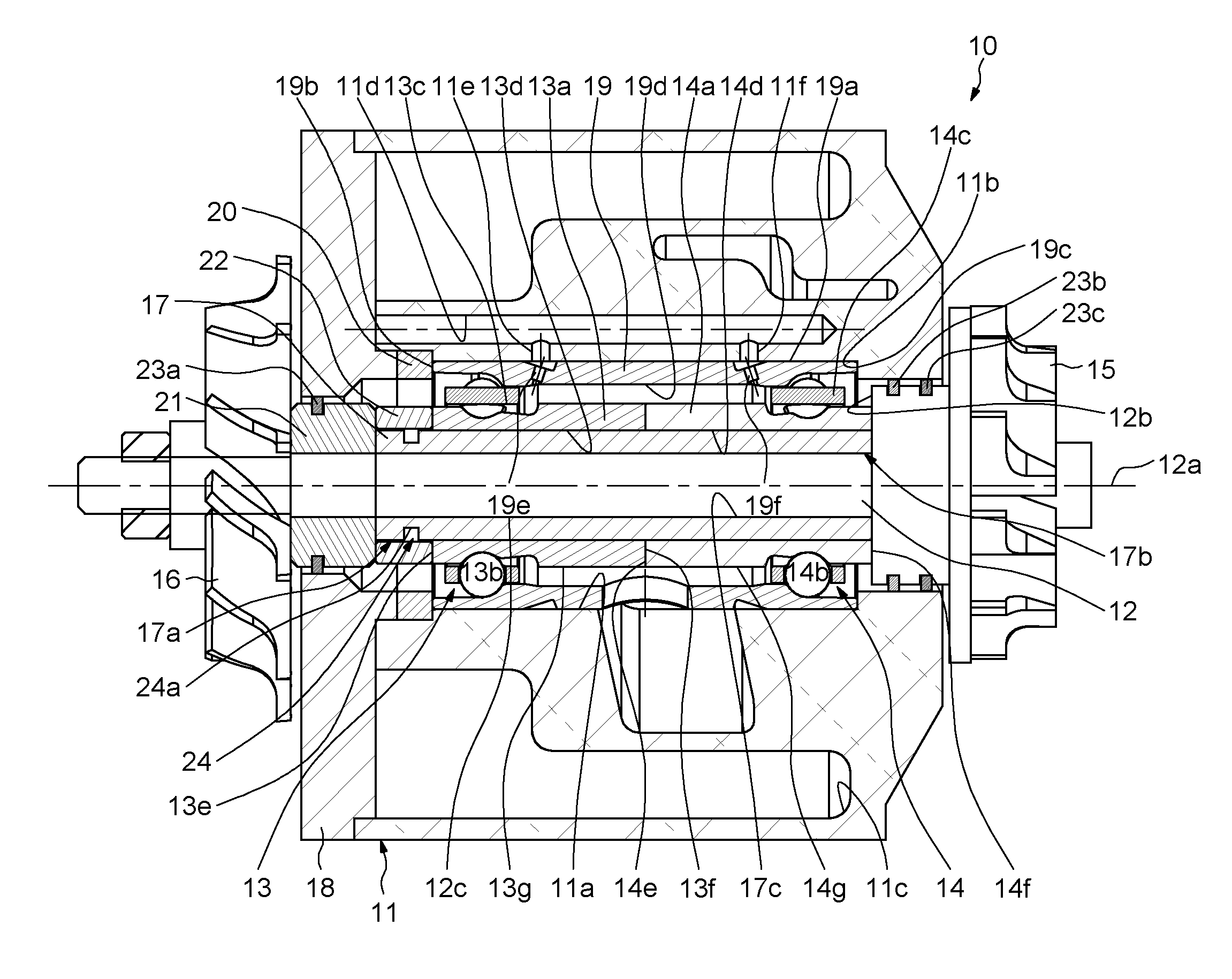

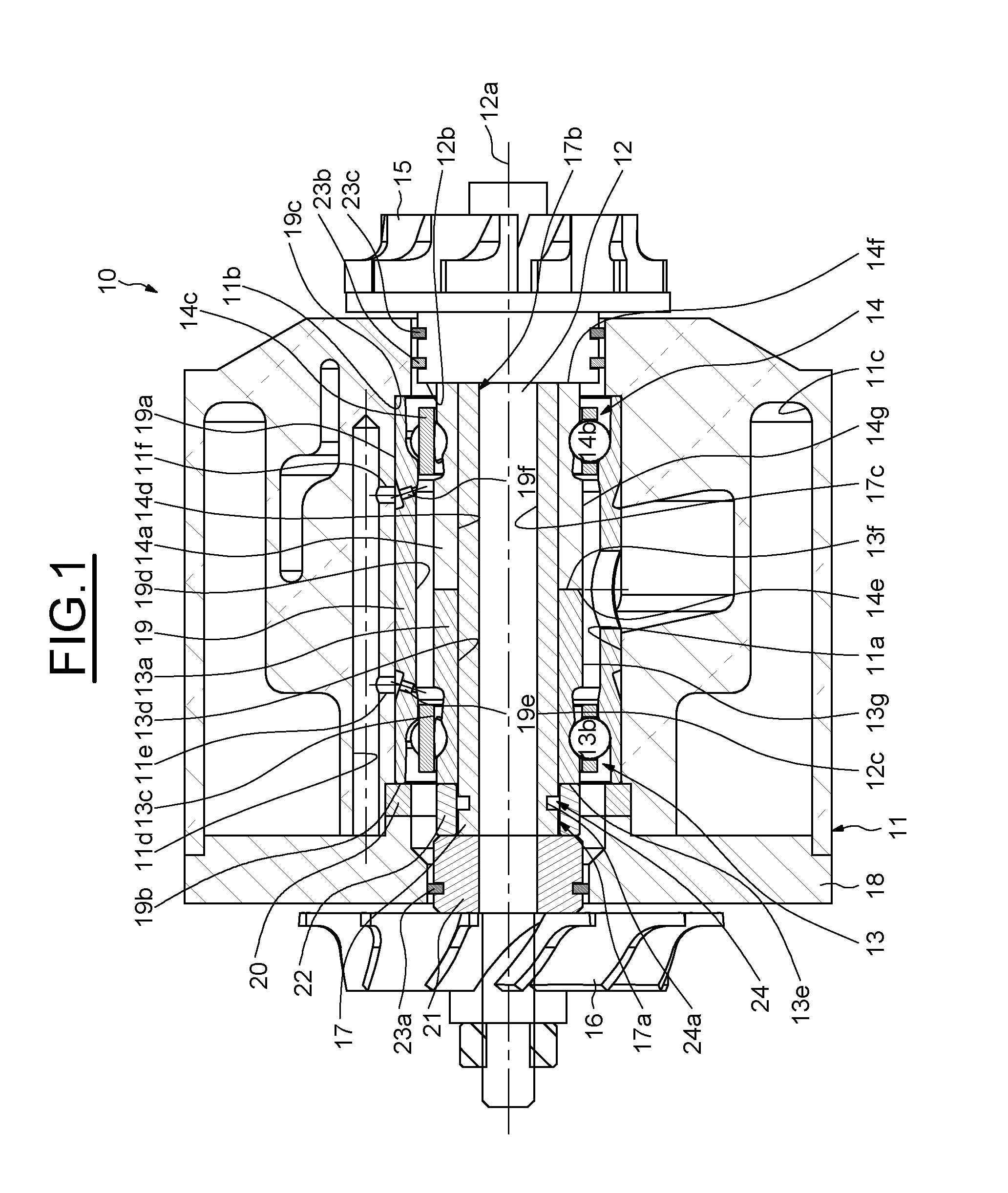

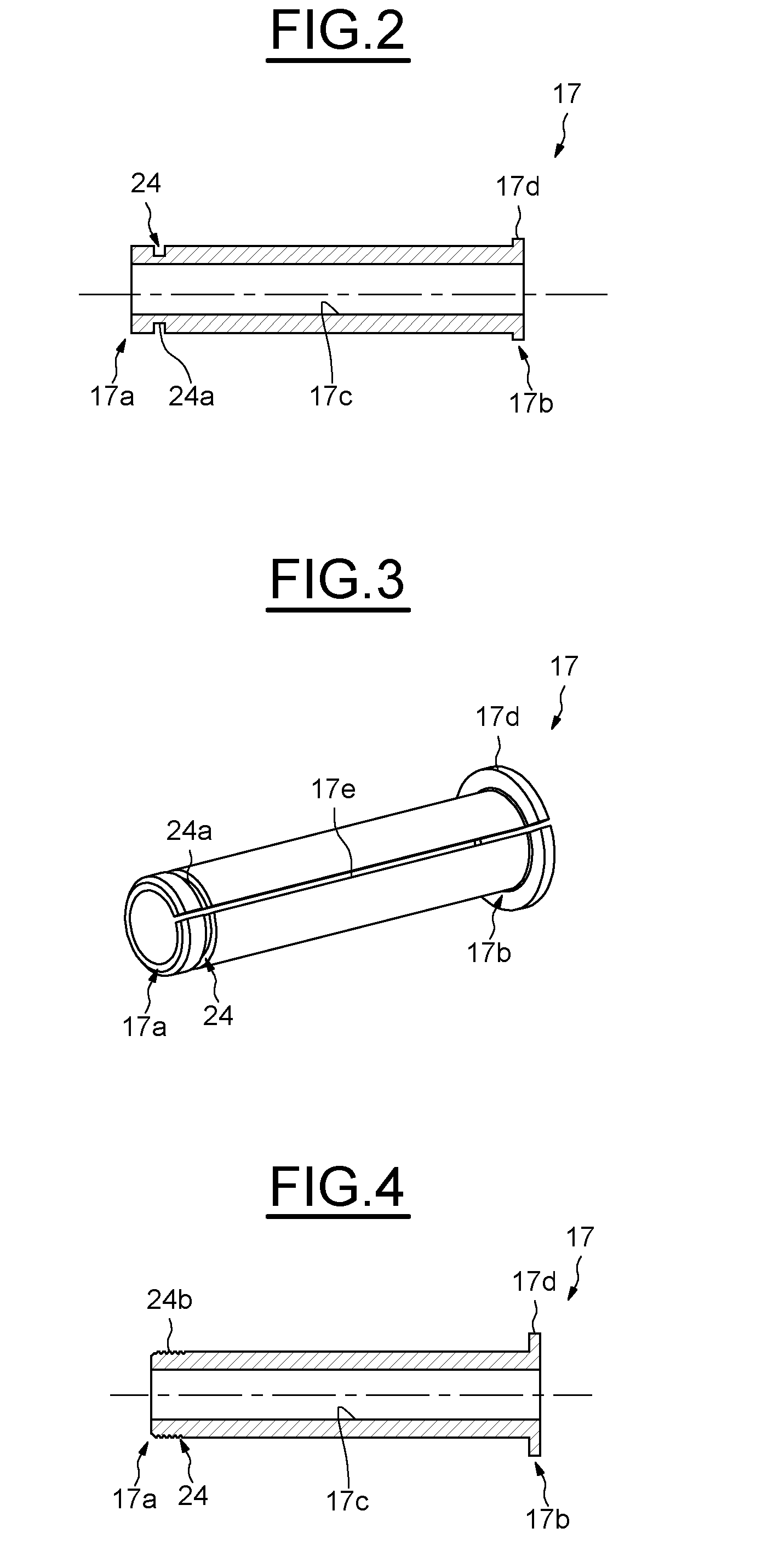

[0031]As illustrated on FIG. 1, which illustrates an embodiment of a turbocharger 10 according to an example of the invention, the turbocharger 10 comprises a housing 11, a shaft 12 extending along an axial axis 12a through a cylindrical bore 11 a or opening of the housing 11, two rolling bearings 13, 14 disposed into the bore 11a, a turbine wheel 15 fixed at one end of the shaft 12, a compressor wheel 16 fixed at an opposite end of said shaft 12, and an intermediate sleeve 17 radially located between the shaft 12 and the rolling bearings 13, 14. The turbocharger 10 also comprises a cap 18 fixed at an axial end of the housing 11.

[0032]Each rolling bearing 13, 14 comprises an inner ring 13a, 14a and an outer ring 19 between which is housed two rows of rolling elements 13b, 14b, which in this case are balls, two annular cages 13c, 14c maintaining the circumferential spacing of the rolling elements 13b, 14b. The axis of each rolling bearing 13, 14 is coaxial with the axis 12a of the sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com