Hybrid gas surface burner

a burner and surface technology, applied in the direction of gaseous heating fuel, stoves or ranges, combustion types, etc., can solve the problems of affecting the efficiency and performance of the burner, the maximum output is limited by the system gas flow handling capability, and the minimum output is limited, so as to achieve the effect of reducing the number of burners, and maintaining high rate performan

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

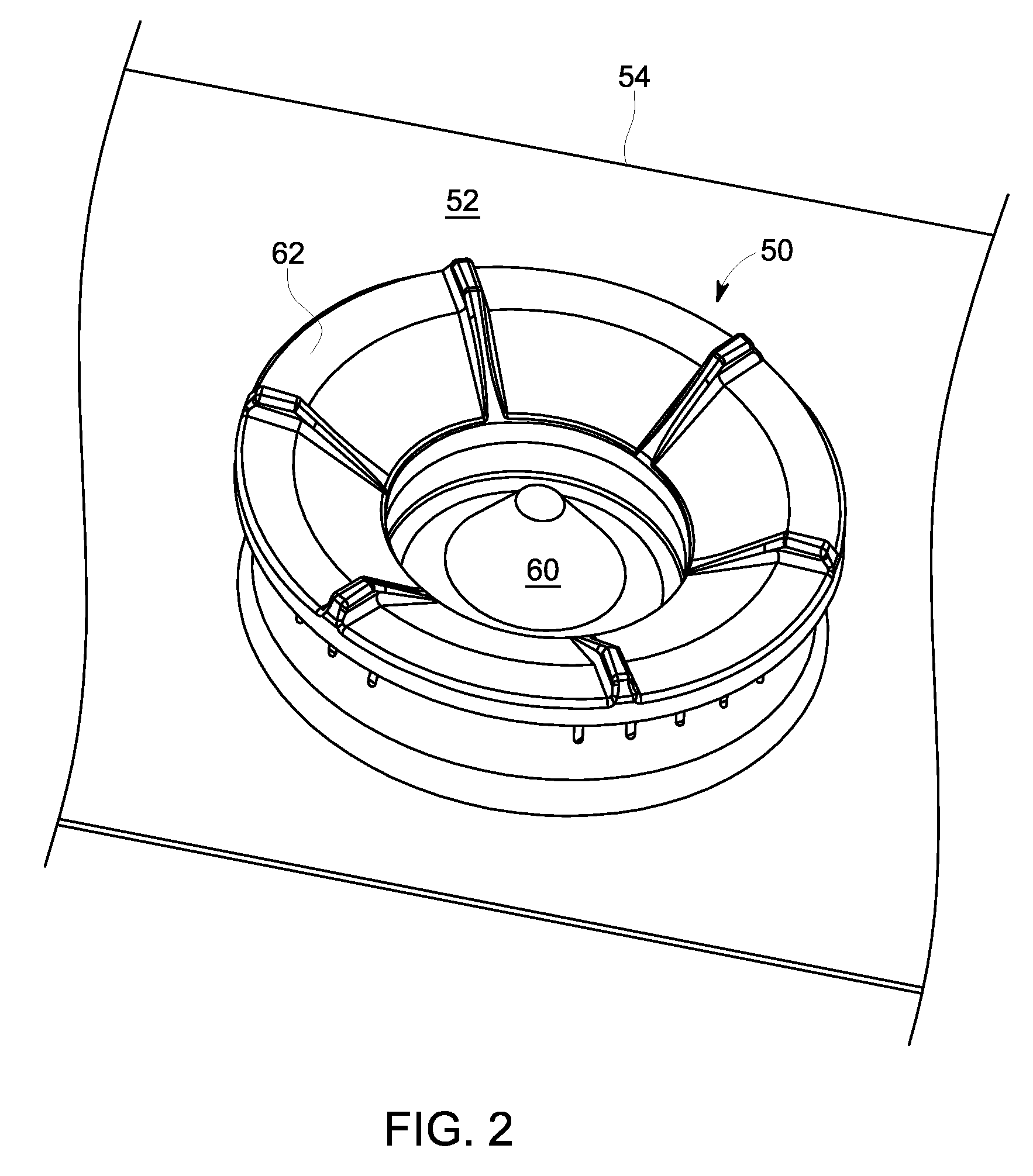

[0026]FIG. 2 is an exemplary burner assembly 50 applicable to gas range 10 shown in FIG. 1. Burner assembly 50 is mounted on a cooktop surface 52 of a cooktop 54, and includes an inner IR burner 60, and an outer gas burner 62 concentric with inner IR burner 60. A number of alternate embodiments of the inner IR burner 60 are discussed further below in conjunction with FIGS. 3 through 6. The particular embodiment of the burner assembly 50 shown in FIG. 2 corresponds to a first embodiment, the details of which are discussed further below in conjunction with FIG. 3. In the exemplary embodiment, cooktop 54 is fabricated from one of steel or glass. Alternatively, cooktop 54 is made of other suitable materials.

[0027]The exemplary gas surface burner 50 of FIG. 2 employs a hybrid approach to surface burners that seeks to take advantage of the benefits of both premixed and atmospheric partially premixed burners. As discussed further below, according to one aspect of the invention, the inner b...

exemplary embodiment 300

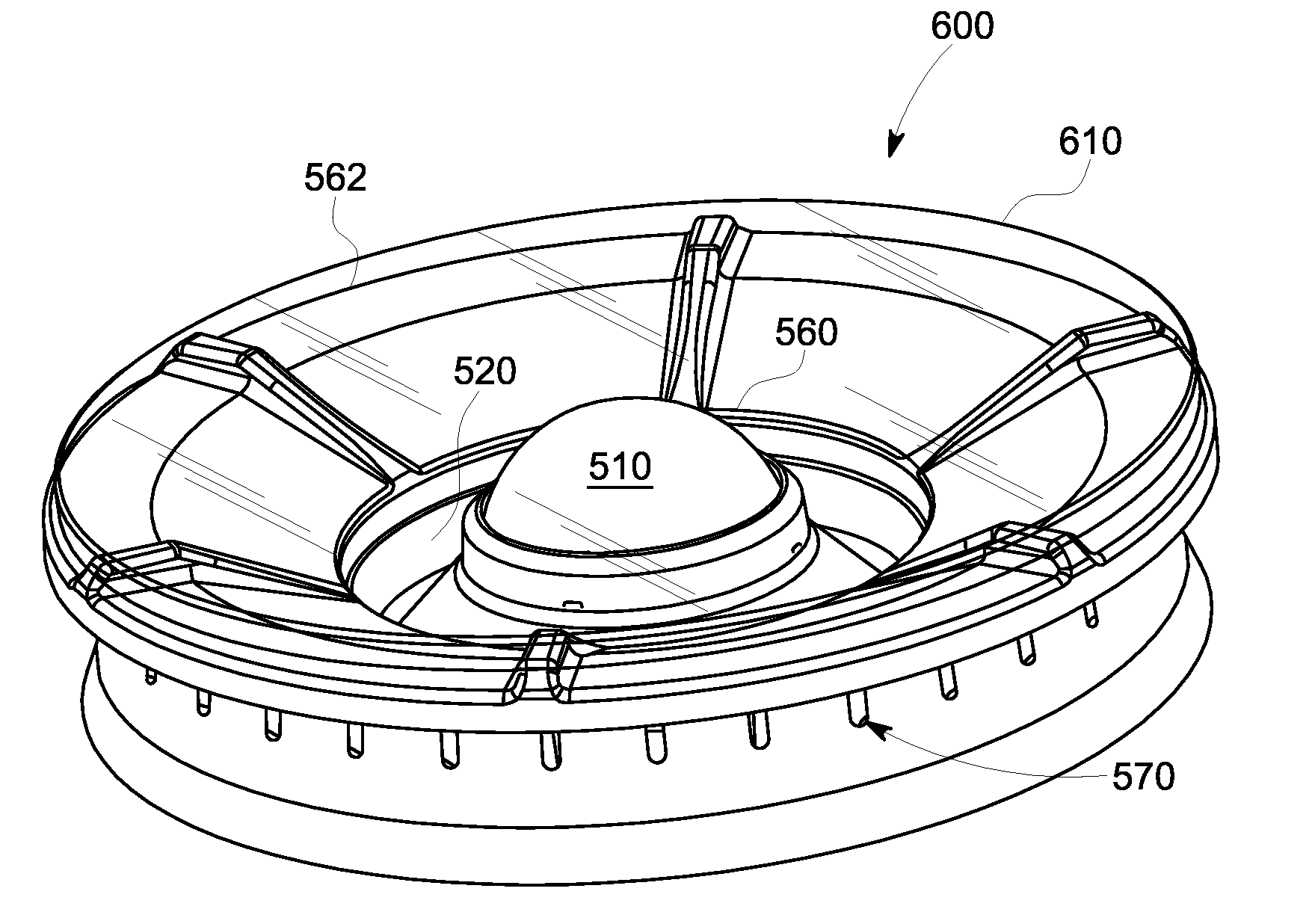

[0029]FIG. 3 illustrates a first exemplary embodiment 300 of the multi-ring burner assembly 50 of FIG. 2. In the exemplary burner assembly 300 of FIG. 3, the central simmer burner 360 is embodied as an annular IR ring 310 that emits IR energy inward towards a centrally located parabolic reflector 320. The exemplary annular IR ring 310 is substantially vertical, that is, it extends axially in a substantially vertical direction relative to the plane of the supporting surface, and can be fabricated, for example, using a stainless steel mesh. The parabolic reflector 320 can be fabricated, for example, using a ceramic material, stainless steel, or another high temperature alloy, such as Inconel™. The shape of the reflector 320 may be manipulated to control the heat flux to the cookware, as would be apparent to a person of ordinary skill in the art. The outer gas burner 362 includes a plurality of ports 370 to support traditional blue flames.

[0030]Among other benefits, an overhang 315 of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com