Electric motor assembly

a technology of electric motors and parts, applied in the direction of dynamo-electric machines, magnetic circuit rotating parts, magnetic circuit shapes/forms/construction, etc., to achieve the effect of reducing the total length of the motor, reducing the cost of the motor, and reducing the siz

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

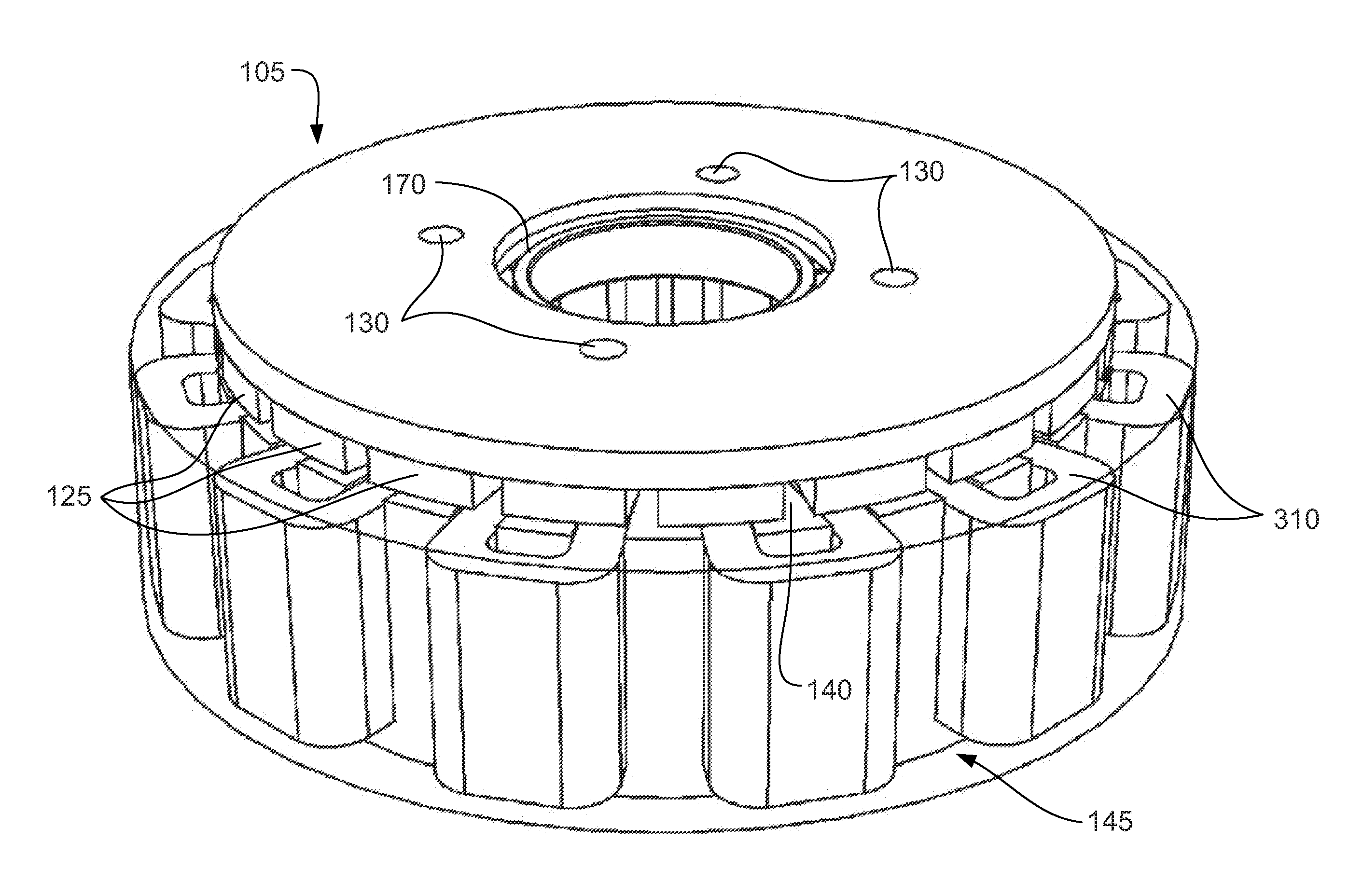

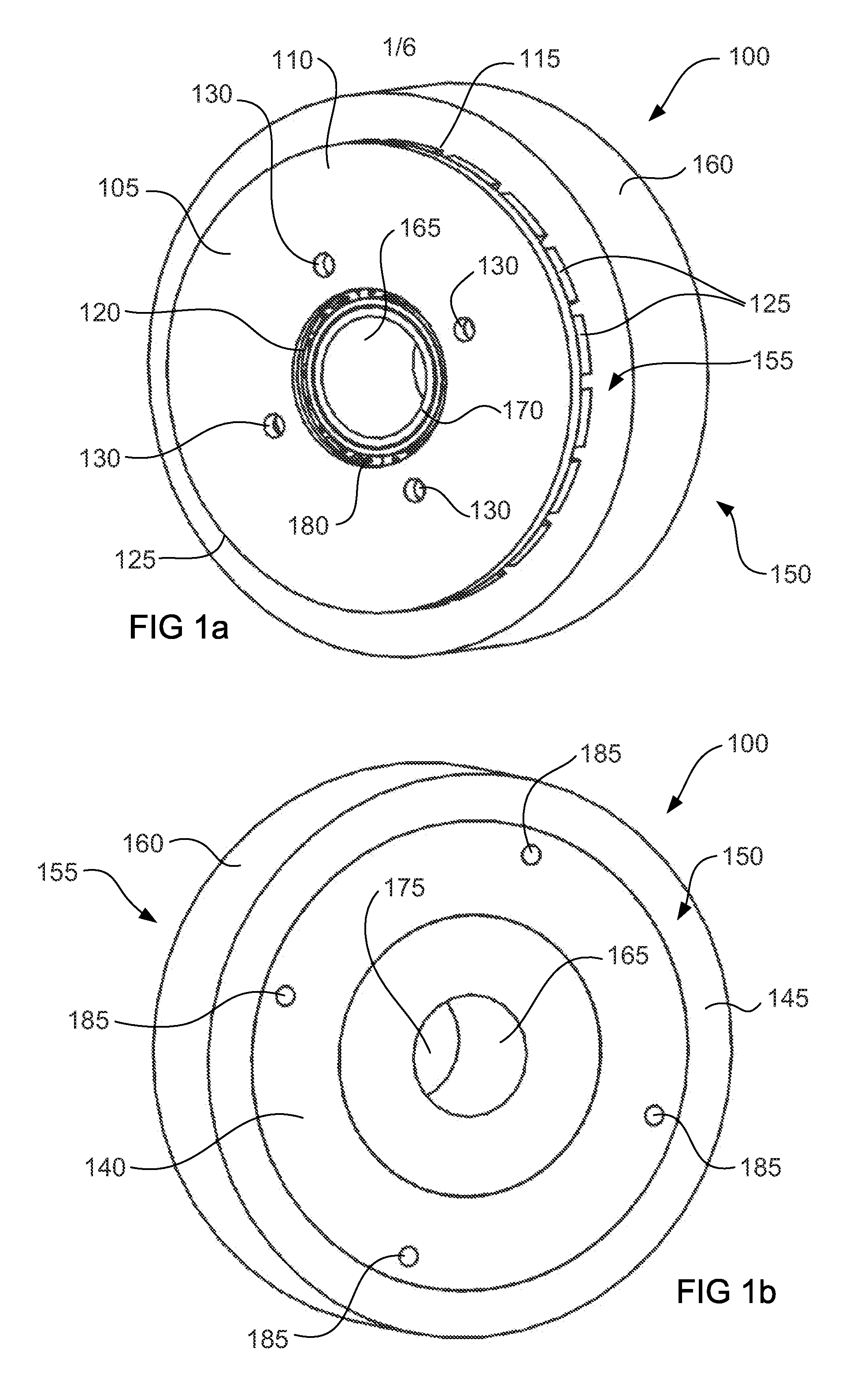

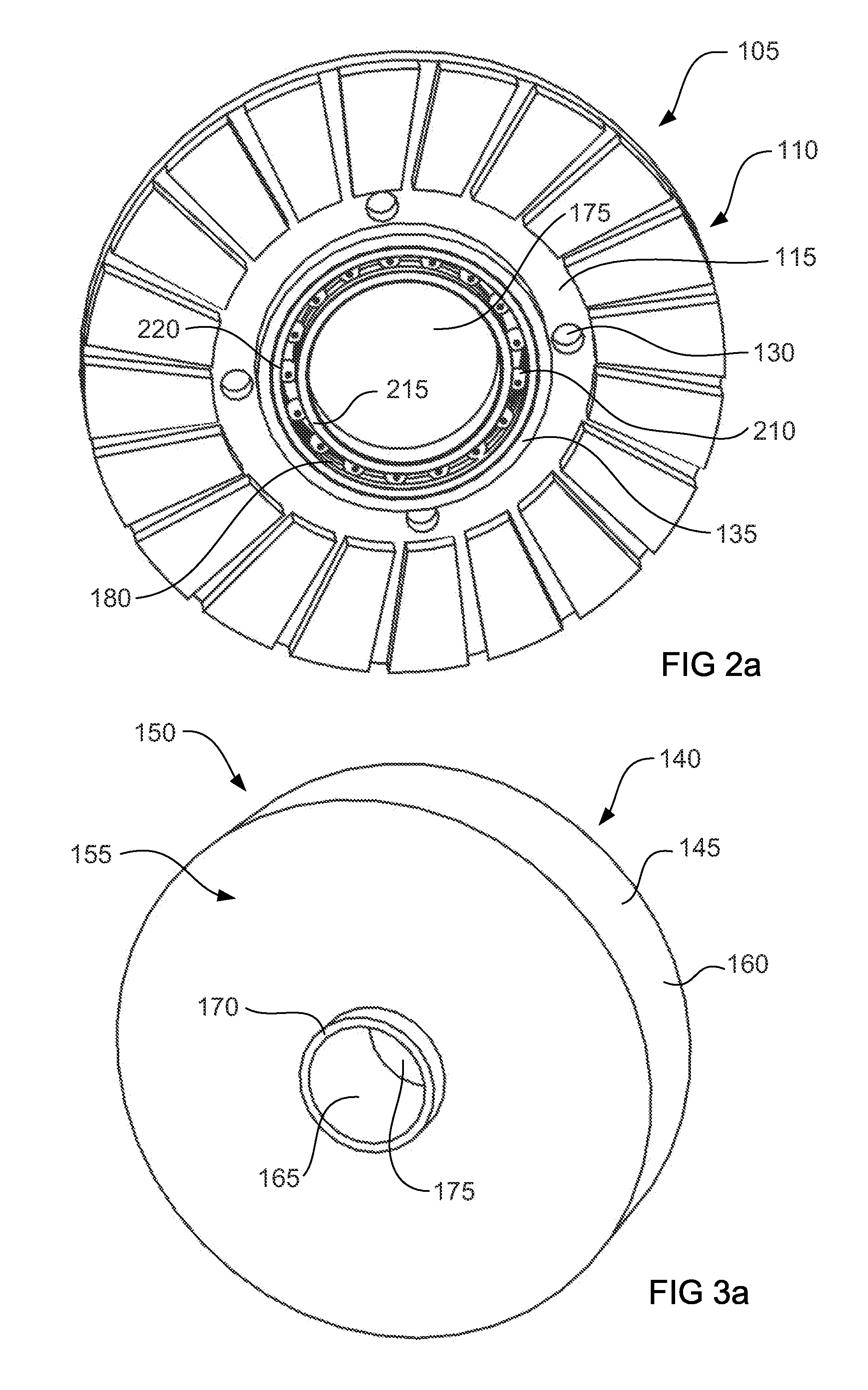

[0047]FIGS. 1a and 1b show a front perspective view and rear perspective view of an axial flux electric flux motor 100 according to the invention. The motor 100 includes a rotor 105, a stator 140 which is housed in a potting material 145 and a bearing assembly 180 which is disposed between the rotor 105 and the stator 140. The rotor 105 is an annular ring having an aperture 175 therethrough. The rotor 105 includes an upper face 110, a lower face 115 and inner wall 120 and an outer wall 125. Located on the lower face 115 is a plurality of magnets 125. The magnets 125 are preferably composed of Neodymium Iron Boron (NdFeB) material, however alternative materials such as Samarium Cobalt or Ferrite will also suffice. Also included on the rotor 105 are rotor mounting apertures 130 and a primary bearing locator 135 (more clearly shown in FIG. 2a). The stator 140 is retained within a potting material 145 which envelops the stator 140 so that the stator 140 is not damaged during operation o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com