Hydrocarbons recovery

a hydrocarbon recovery and hydrocarbon technology, applied in the field of hydrocarbon recovery, can solve the problem that the primary recovery technique is only capable of producing a small fraction, and achieve the effect of increasing or decreasing salinity, adjusting salinity, and increasing salinity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

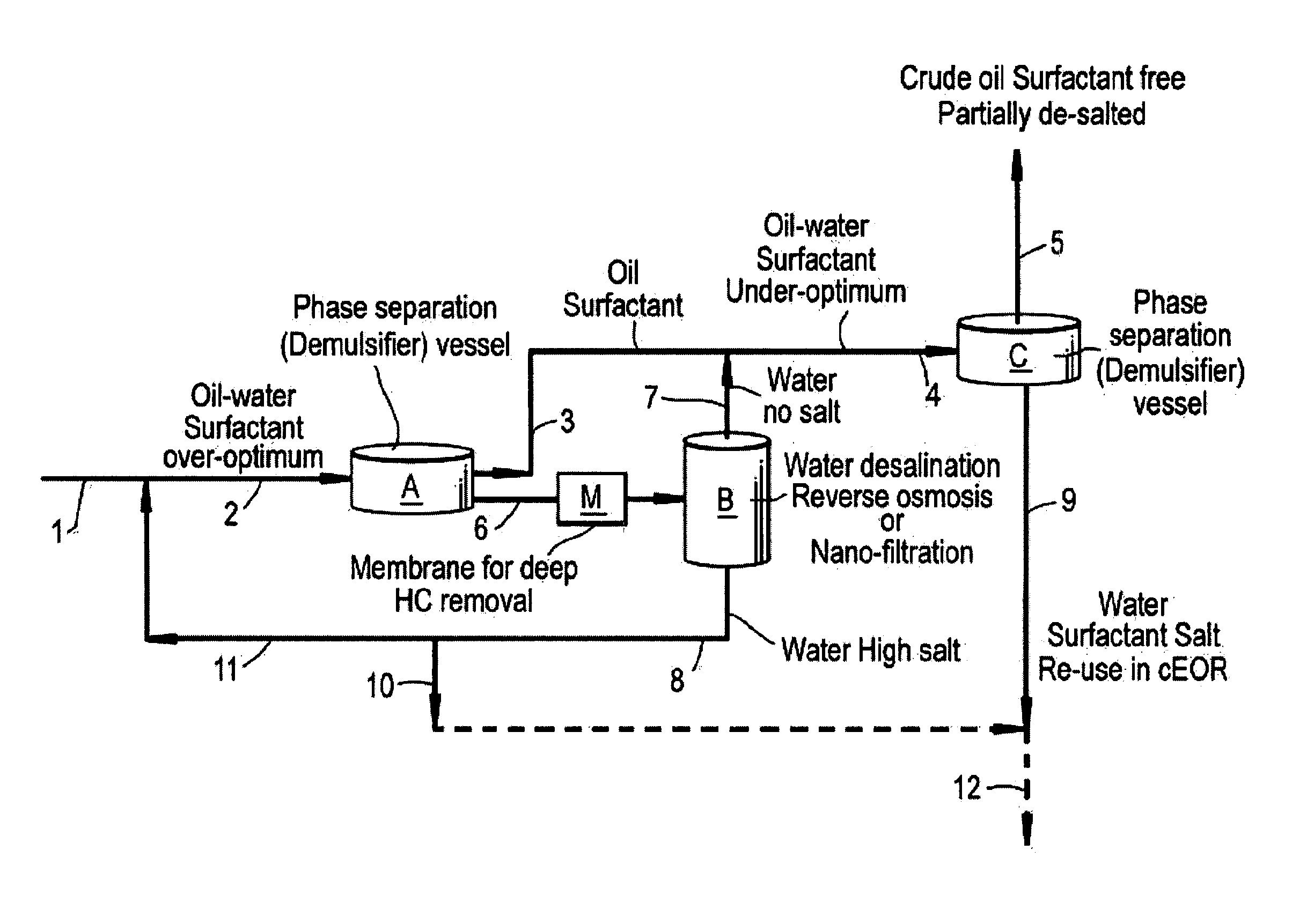

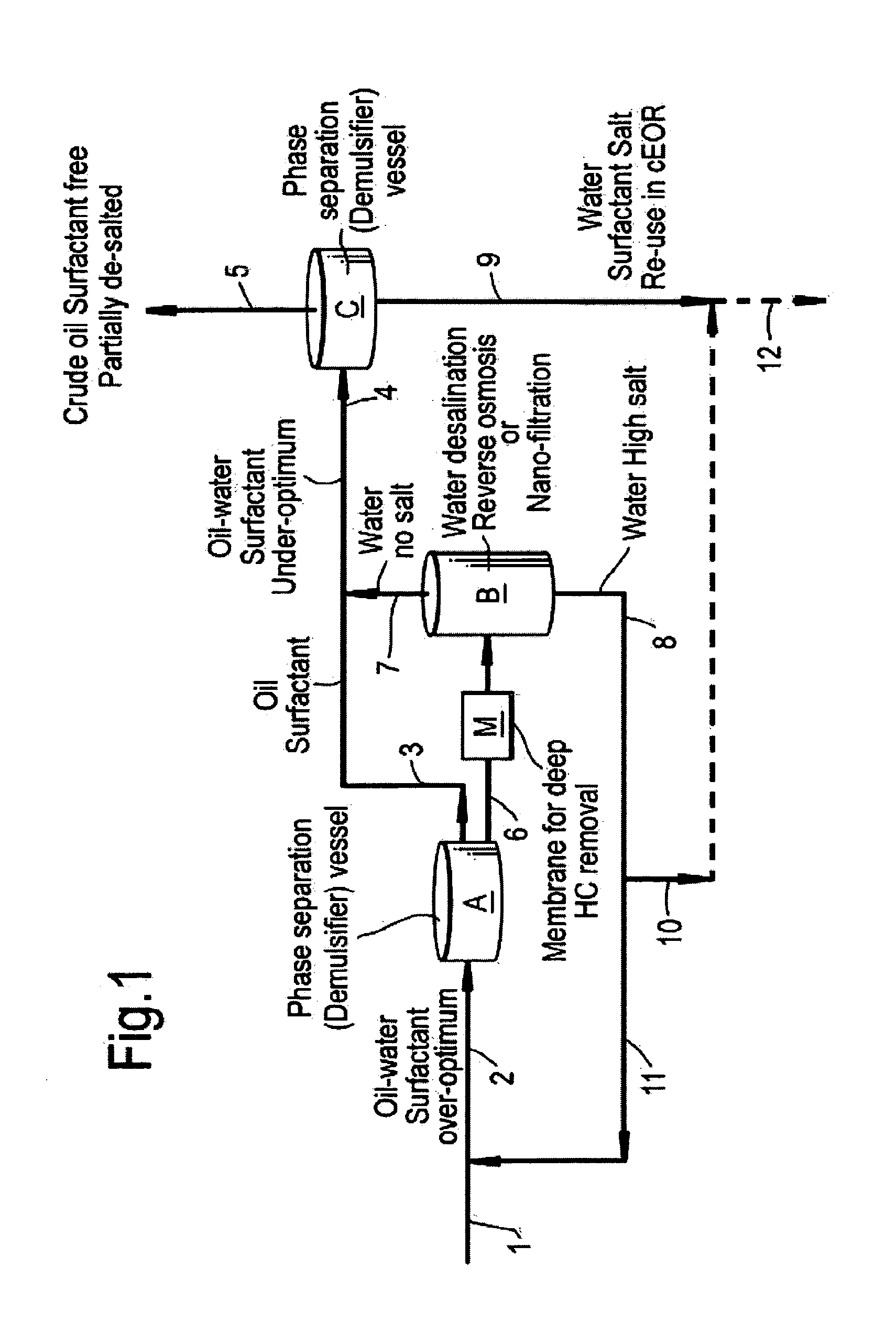

[0046]FIG. 1 is a schematic diagram of a hydrocarbons separation system for separating hydrocarbons from a hydrocarbons recovery mixture according to the invention;

second embodiment

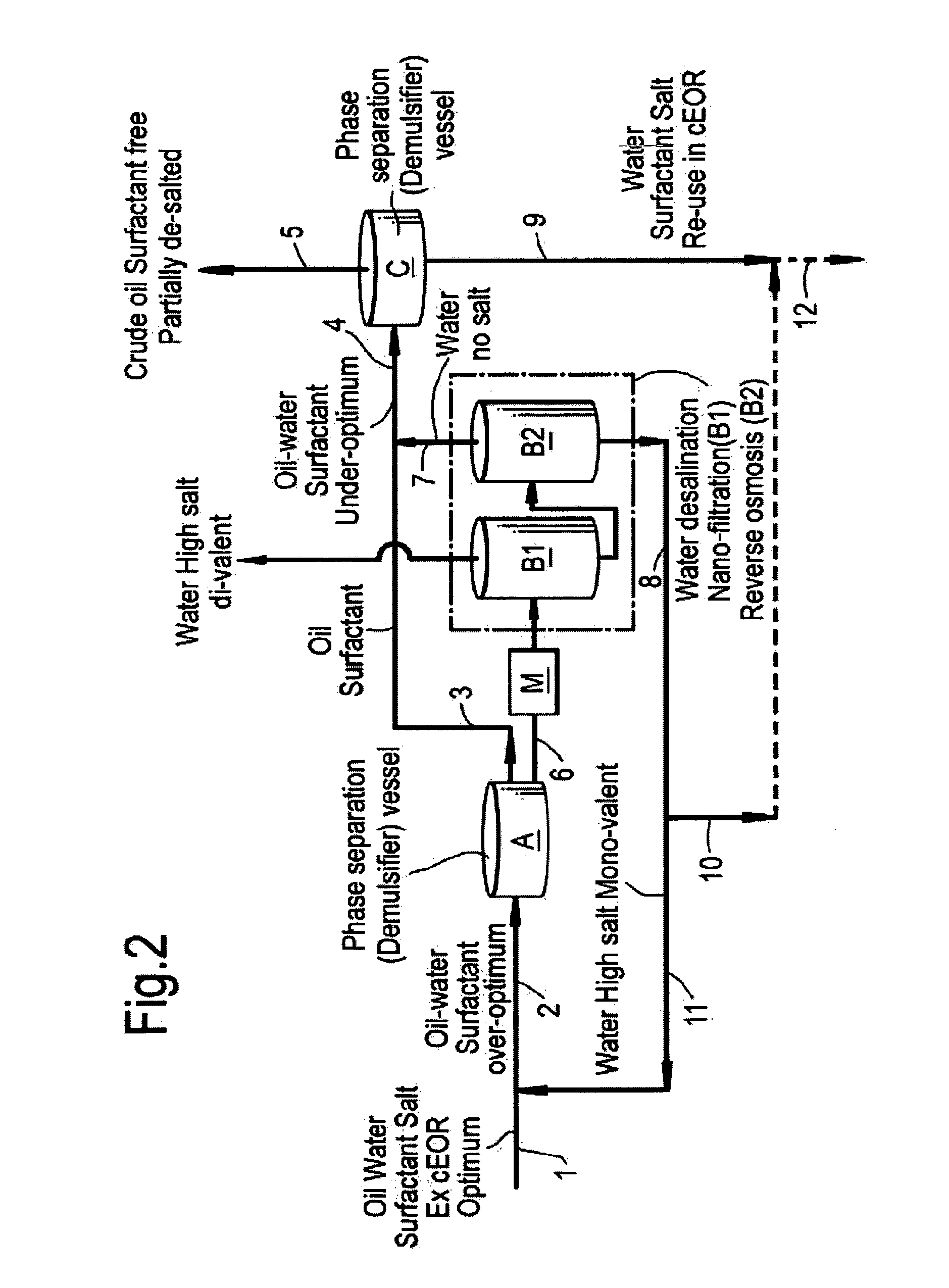

[0047]FIG. 2 is a schematic diagram of a hydrocarbons separation system for separating hydrocarbons from a hydrocarbons recovery mixture according to the invention; and

third embodiment

[0048]FIG. 3 is a schematic diagram of a hydrocarbons separation system for separating hydrocarbons from a hydrocarbons recovery mixture according to the invention.

[0049]With reference to FIGS. 1 to 3, the hydrocarbons separation systems and methods (or processes) according to three exemplary embodiments of the invention described below each serve to extract or separate a hydrocarbon phase from an input mixture. The input mixture comprises an emulsion of water and hydrocarbons in the presence of a surfactant (surface-active agent). Whilst the input mixture could stem from any suitable source, in practice, such mixtures are most commonly obtained from chemical enhanced oil recovery (cEOR) streams.

[0050]The hydrocarbons separation systems and methods according to the three exemplary embodiments of the invention comprise adjusting, specifically increasing, the salinity of the input mixture to release hydrocarbons and water from the emulsion into a hydrocarbon phase and a salt-containin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com