Semiconductor manufacturing device and manufacturing method thereof

a manufacturing device and semiconductor technology, applied in the direction of mechanical equipment, water supply installation, transportation and packaging, etc., can solve the problems of defective contacts, decrease in signal transmission speed of semiconductor devices, increase in power consumption, etc., to prevent the oxidation of metal layers, increase power consumption, and prevent the effect of occurren

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0005]Technical Objective

[0006]The technical objective of the present invention is to provide a semiconductor manufacturing device and manufacturing method capable of preventing the oxidation of a metal layer or the like of a substrate during an annealing process on the substrate.

[0007]Technical Solution

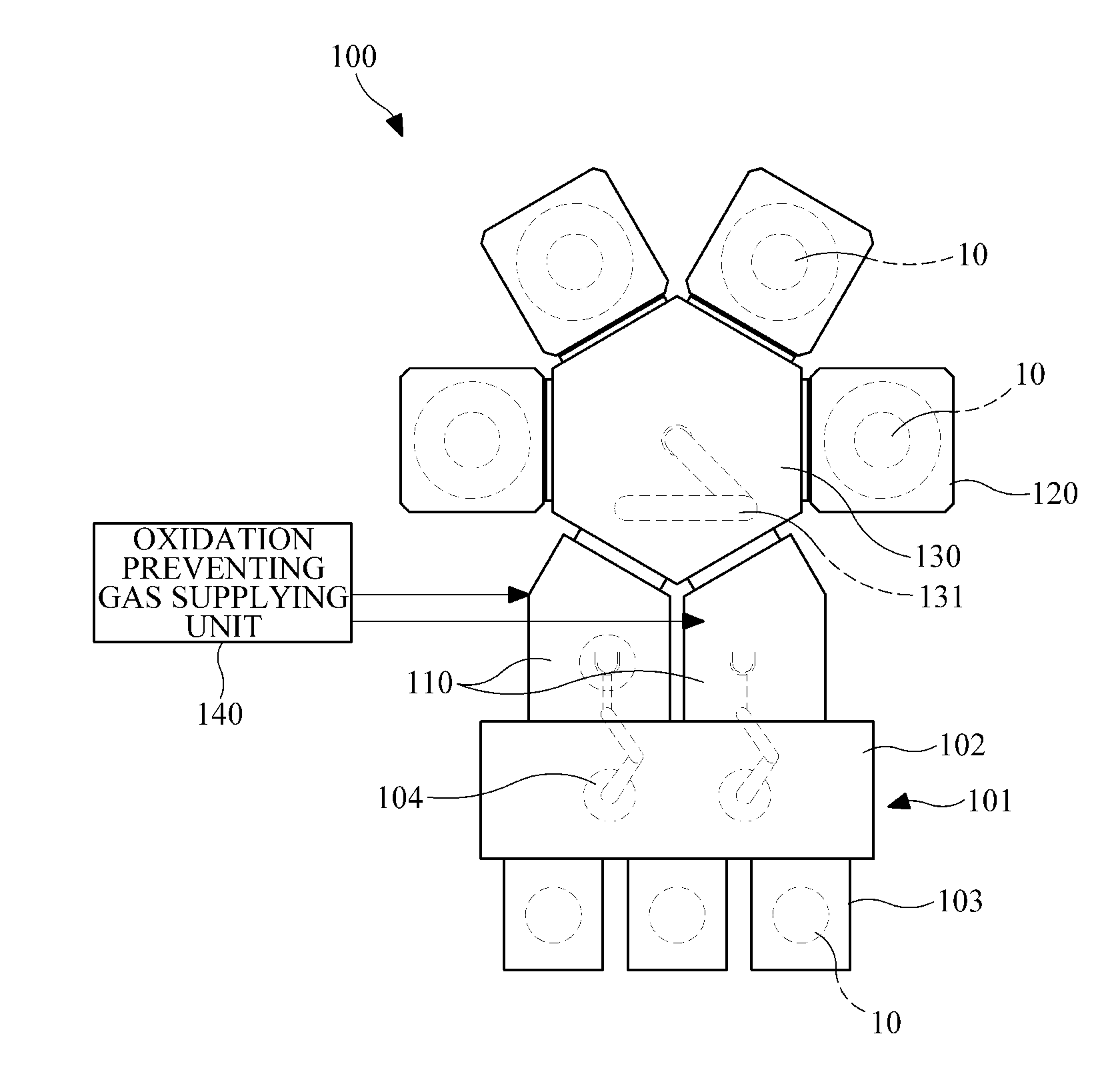

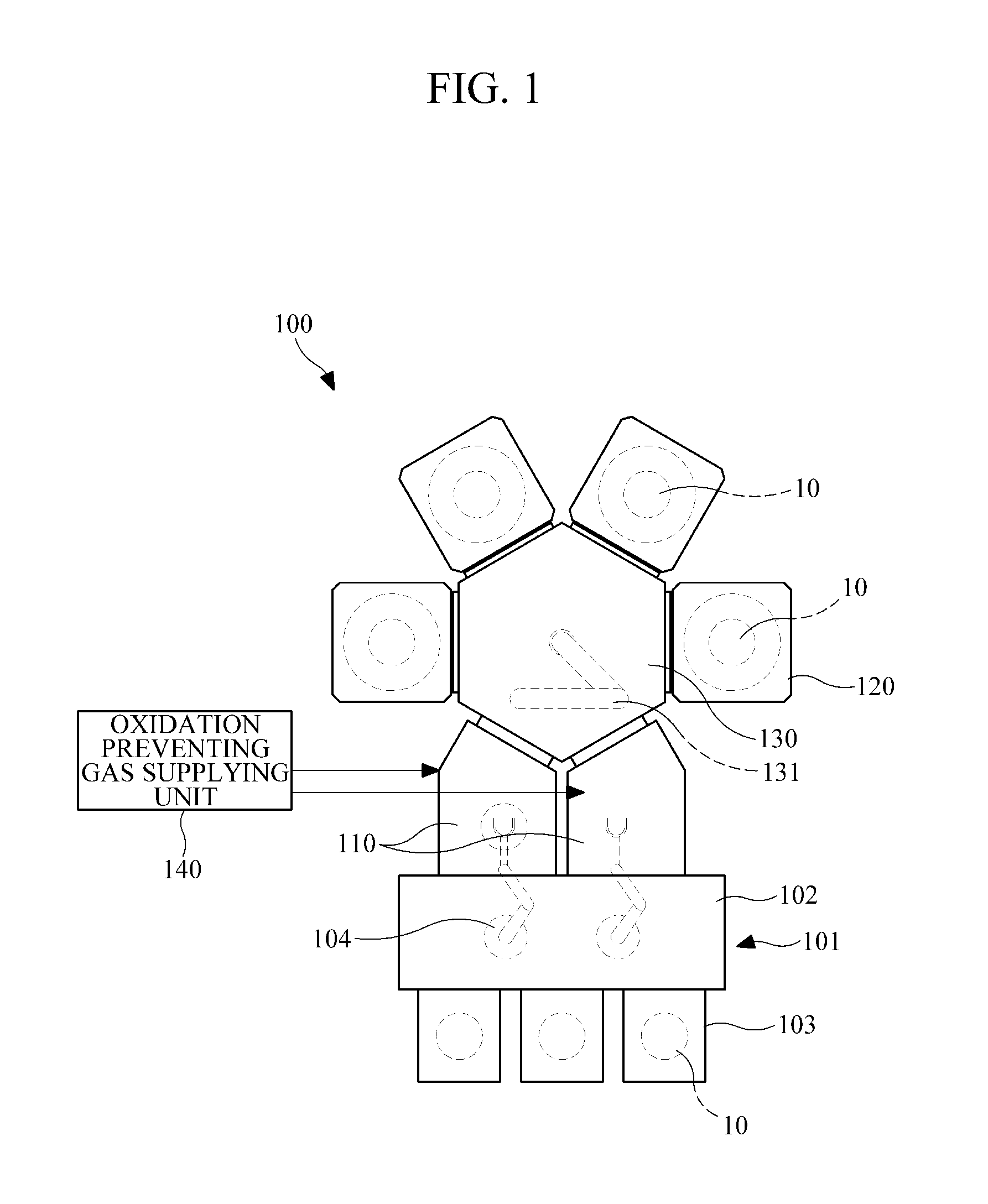

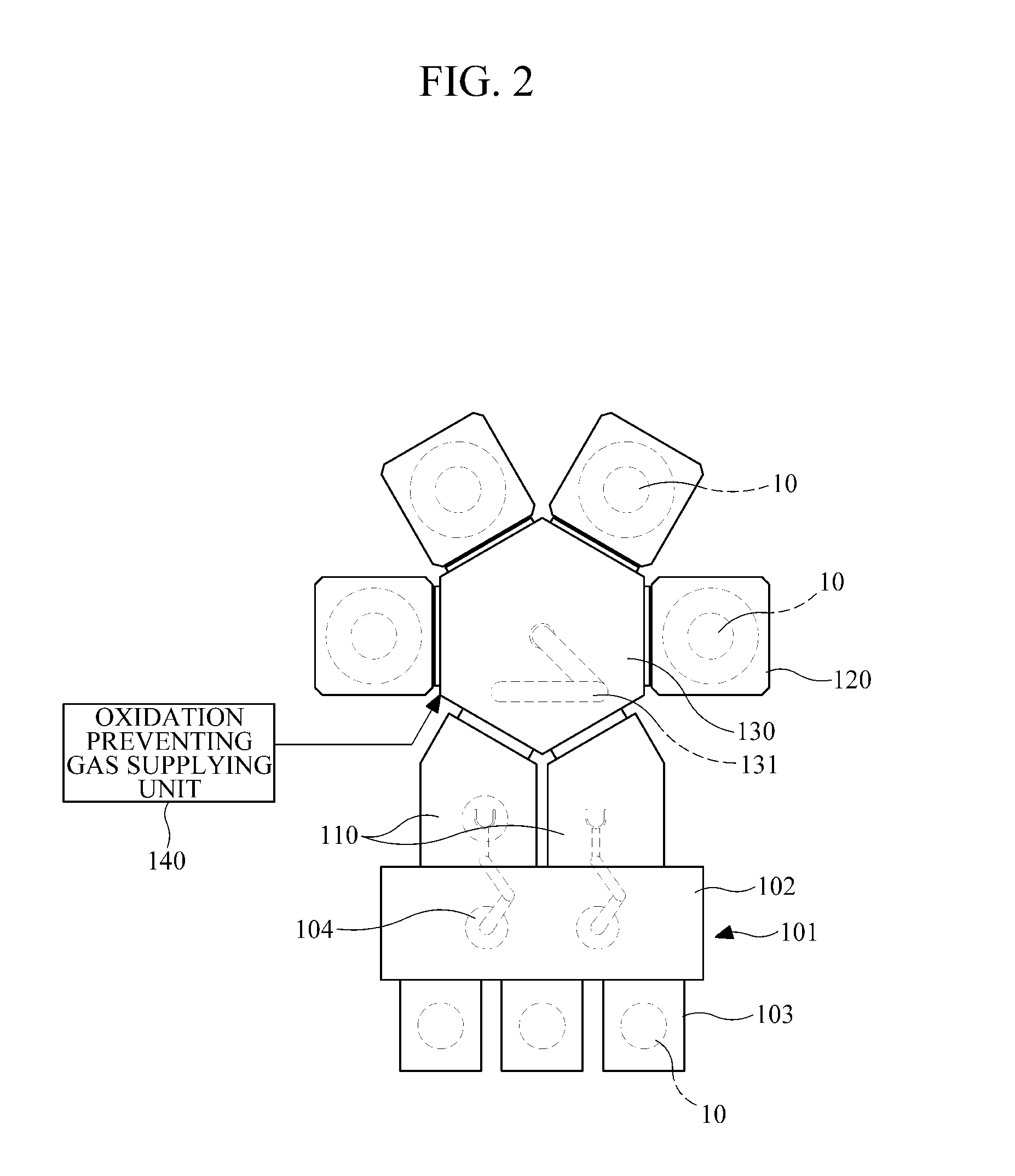

[0008]According to an exemplary embodiment of the present invention, a semiconductor manufacturing device may include: a loadlock chamber; one or more process chamber configured to receive a substrate and perform an annealing process; a transfer chamber configured to transfer the substrate between the loadlock chamber and the process chamber; and an oxidation preventing gas supplying unit configured to supply an oxidation preventing gas to at least one of the transfer chamber and the loadlock chamber.

[0009]According to another exemplary embodiment of the present invention, a semiconductor manufacturing method may include: transferring a substrate into a process chamber from a loadloc...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap