Enhanced oil recovery initiated with zero emission in-situ combustion

a technology of in-situ combustion and petroleum fluid, which is applied in the direction of fluid removal, earthwork drilling and mining, and well accessories, etc. it can solve the problems of high oxygen concentration, fire and/or explosion, and well destruction, and achieves enhanced recovery of petroleum fluids, high oil displacement efficiency, and promote gravity segregation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

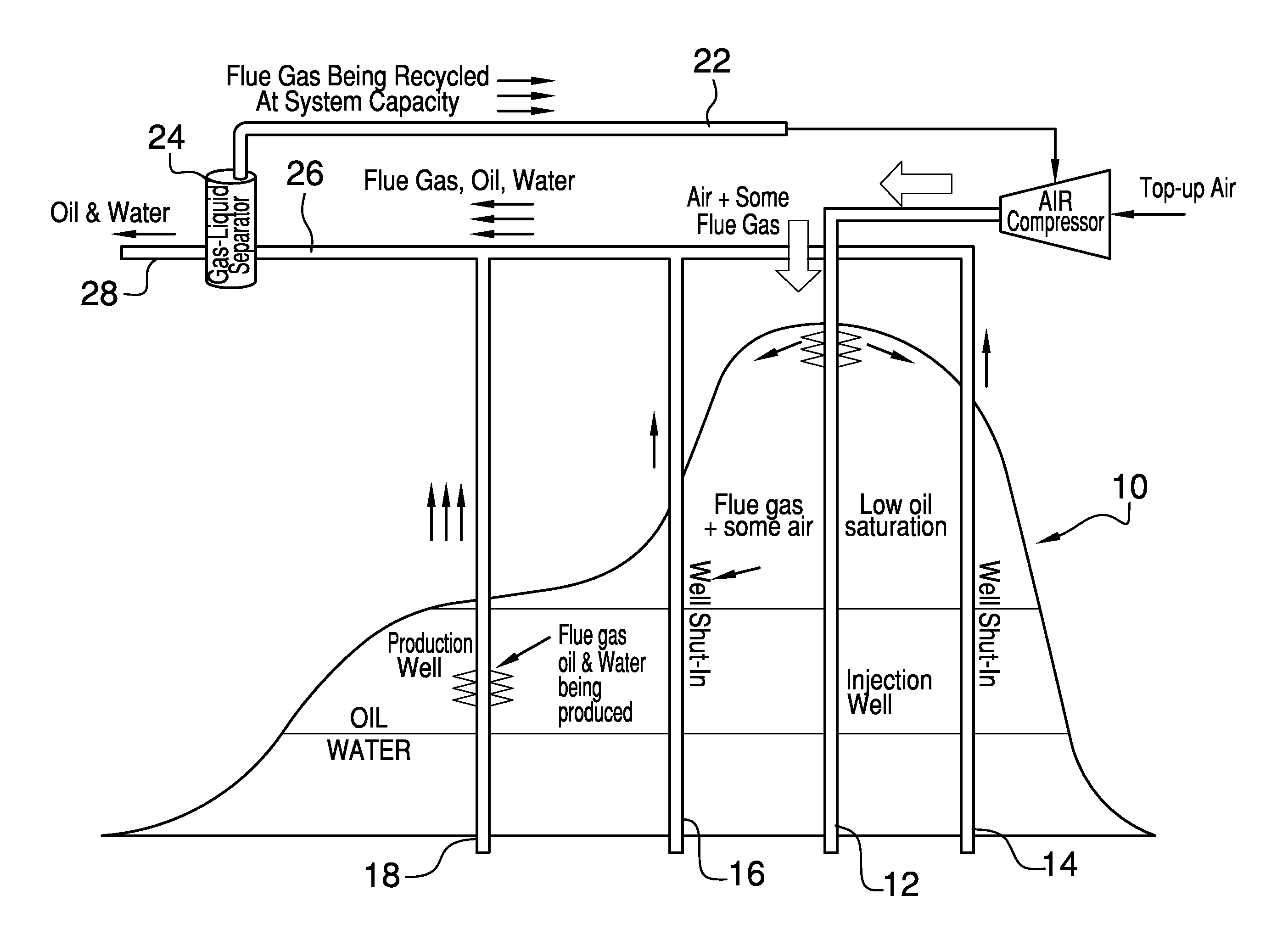

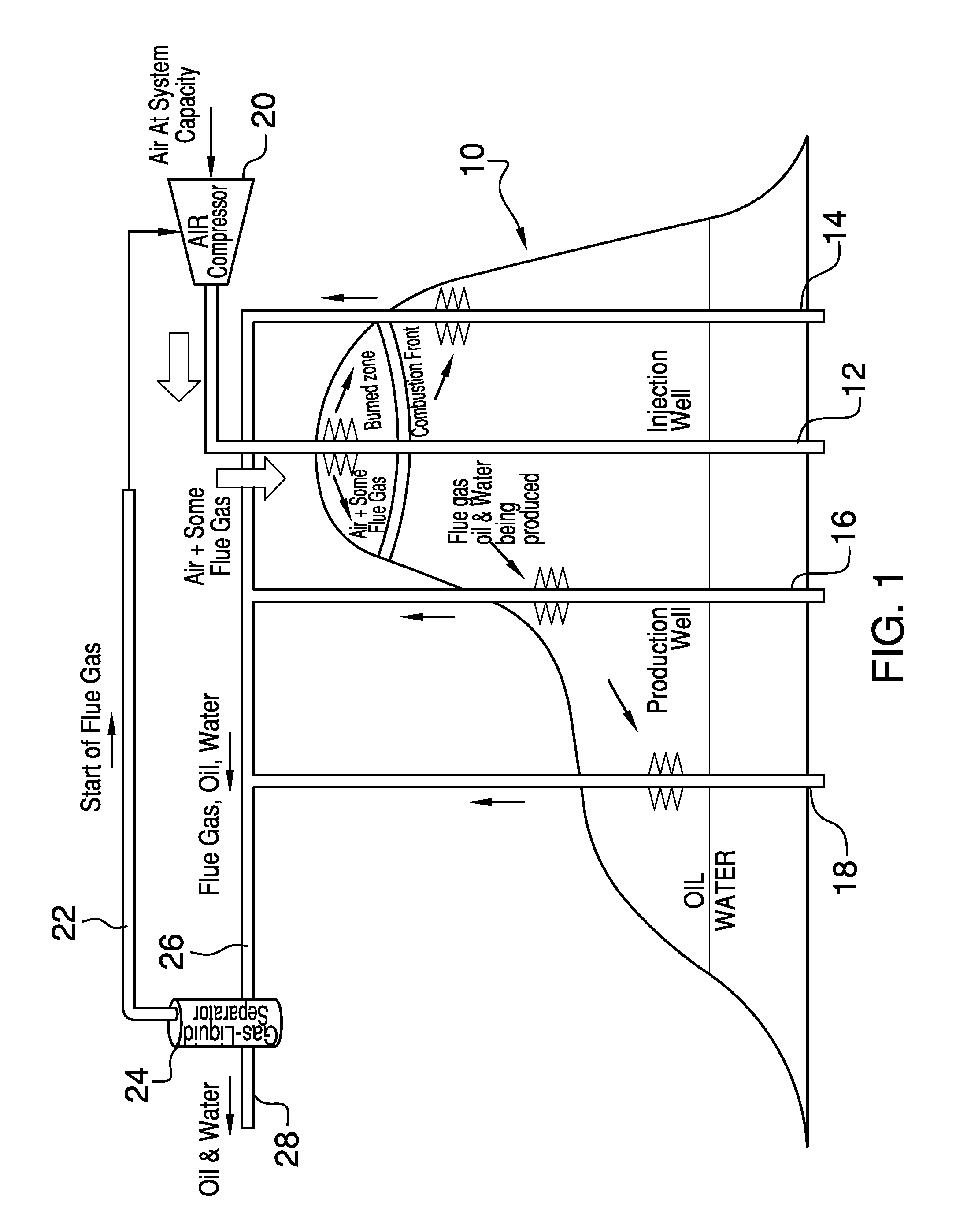

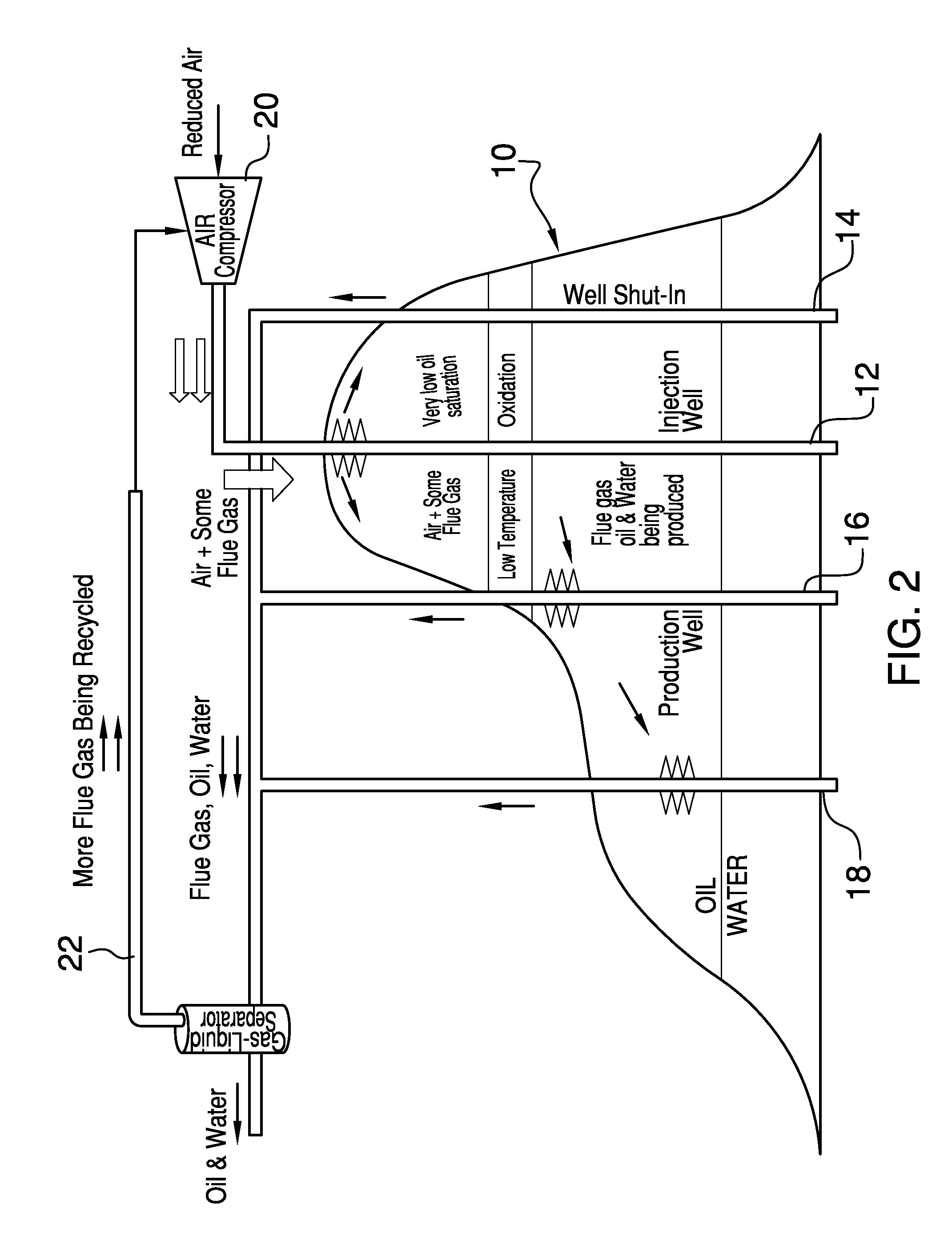

[0027]Several embodiments of the present invention are described below and illustrated in the accompanying drawings. In embodiments, there is an in-situ combustion method for the enhanced recovery of petroleum fluids from vertical or high relief subterranean formations or reservoirs where gravity segregation of flue gas and oil is utilized to provide increased sweep efficiency by controlling the rate in which flue gas is produced and by recycling recovered flue gas back into the well to establish and maintain well pressure, while reducing and ultimately eliminating oxidizing gas injection. Although the oxidizing gas may be any gas or mixture of gases that support combustion, in an embodiment, the oxidizing gas is atmospheric air. Advantages of using atmospheric air include being readily available at the well site and not requiring specialized equipment to provide a suitable supply for formation injection.

[0028]All of the flue gas produced from the formation is separated from formati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com