Pump and actuator

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

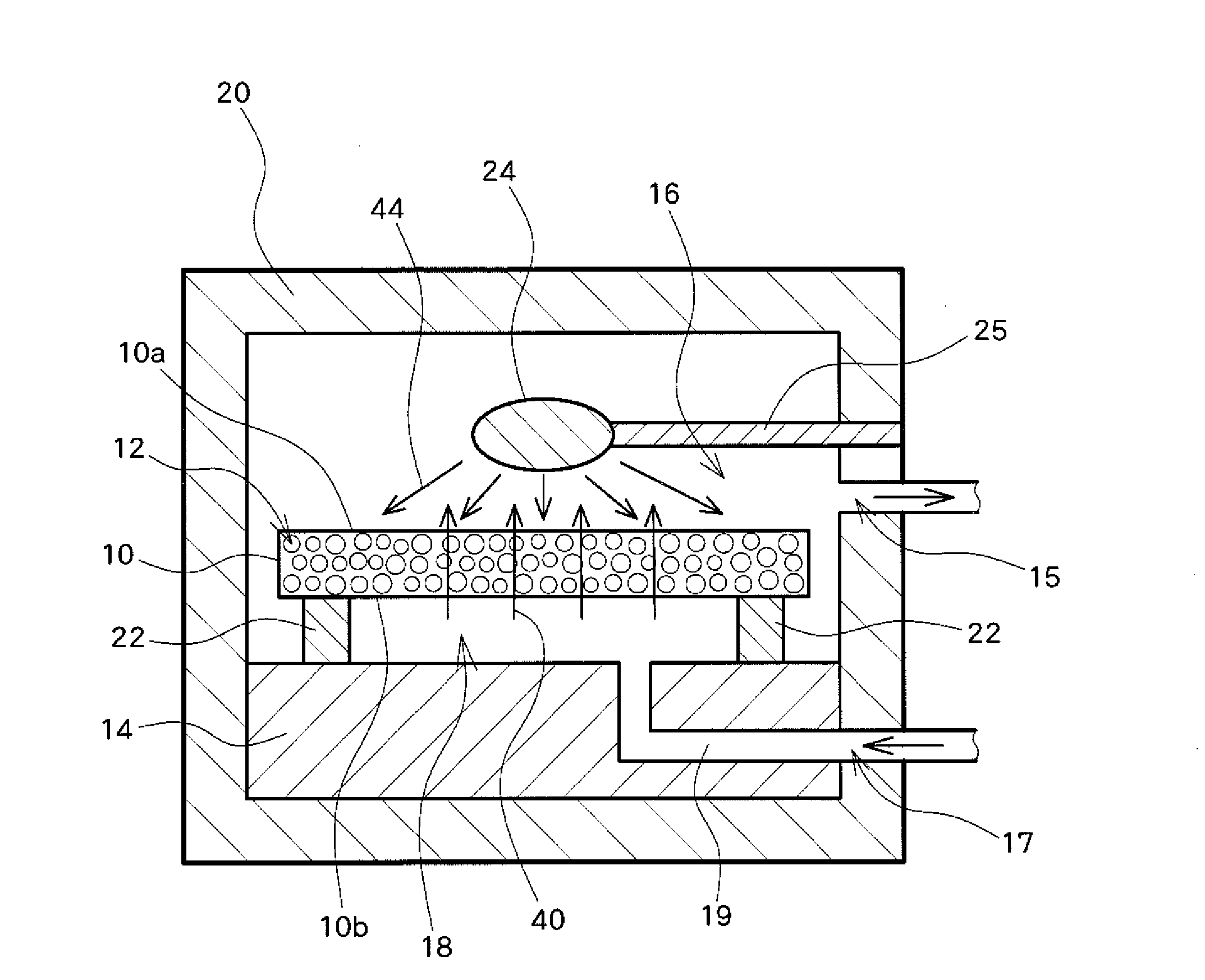

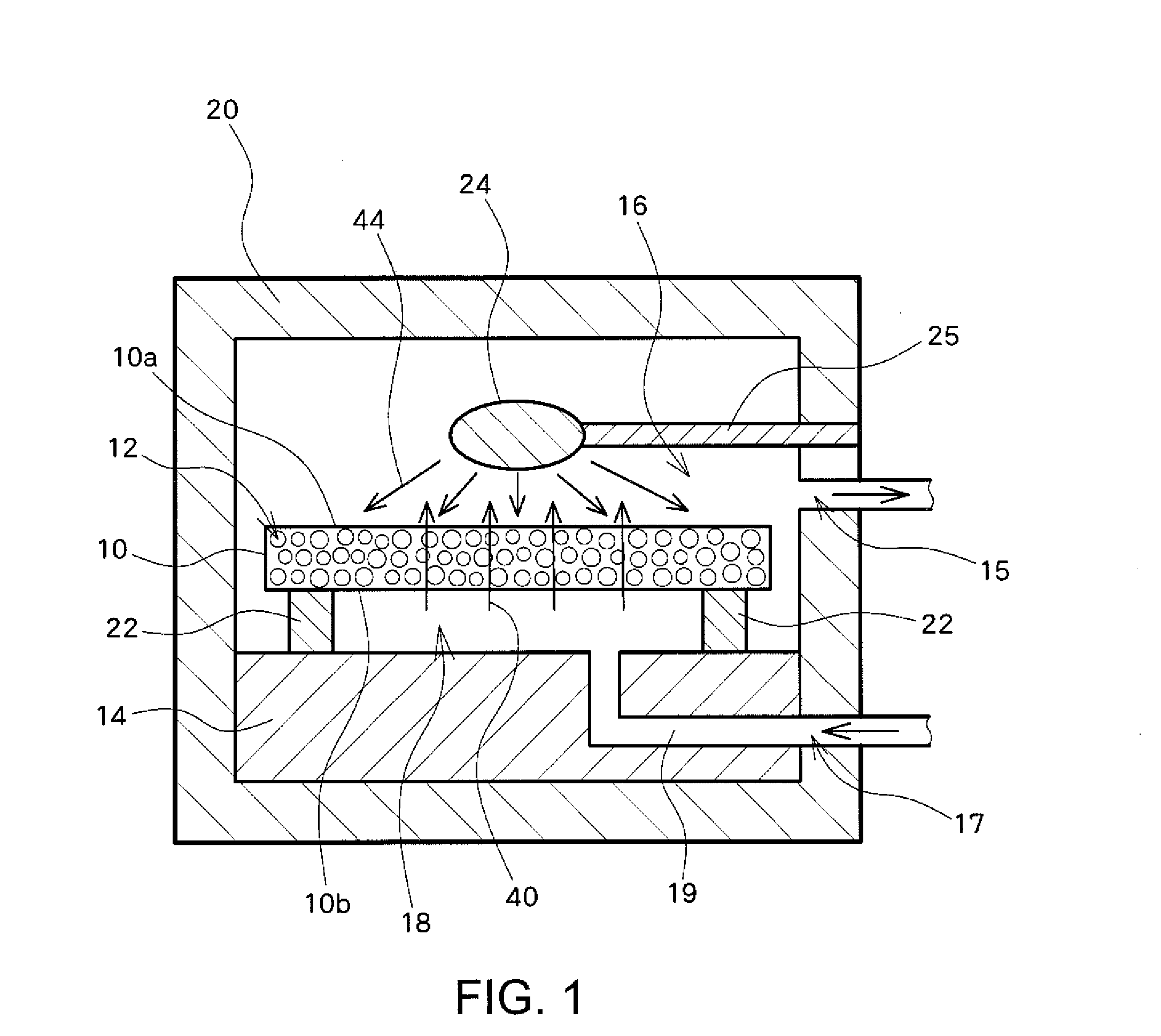

[0050]Hereinafter, an embodiment of the present invention will be described with reference to the drawings.

[0051]FIG. 1 is a diagram showing a general configuration of a pump according to the embodiment of the present invention.

[0052]The pump according to the present embodiment is a thermally driven molecular flow pump which can pressurize or depressurize a gas by using a thermal transpiration flow.

[0053]A porous membrane 10 disposed in a casing 20 is made of a material having a low thermal conductivity (0.2 [W / (m·K)] or less) such as a silica aerogel membrane in which a large number of pores 12 are formed in a silicon dioxide (silica, SiO2) material. A first space 16 is formed between the casing 20 and a front surface (first surface, one main surface) 10a of the porous membrane 10. A second space 18 is formed between a heat sink (heat radiation device) 14 disposed in the casing 20 and a rear surface (opposite second surface different from the first surface (one main surface)) 10b o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com