Multi-position adjustable height seat post

a seat post and multi-position technology, applied in the direction of rod connections, machine supports, cycle equipments, etc., can solve the problems of fast ageing of product appearance, difficult to achieve manufacturing progress, and wear of inner tubes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

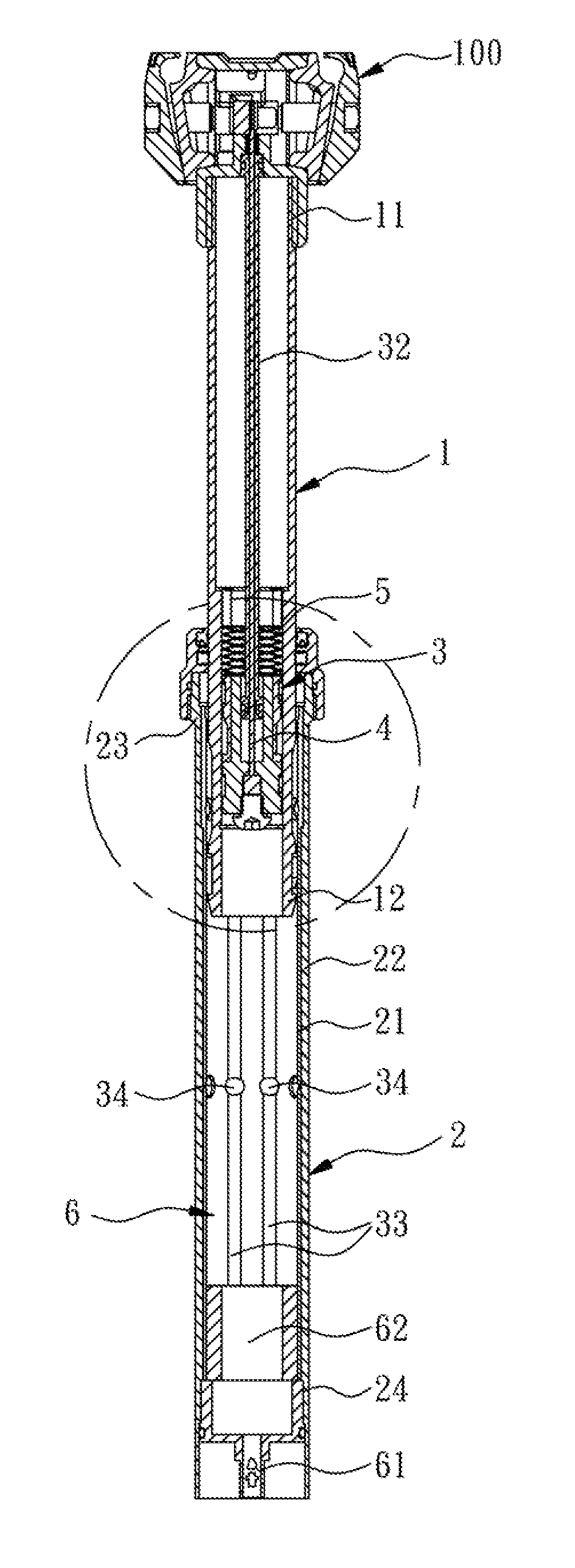

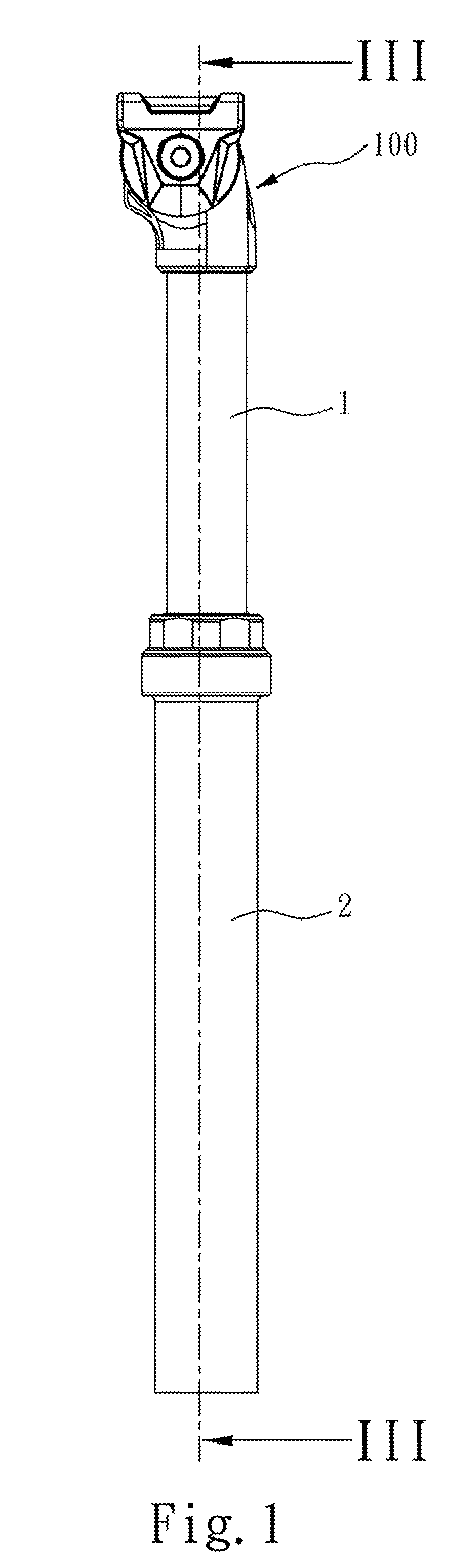

[0030]Referring to FIGS. 1-4, a multi-position adjustable height seat post in accordance with the present invention is usually mounted on the frame of a bike (not shown) and essentially to comprises an inner tube 1, an outer tube 2, a locking assembly 3, a triggering device 4, a first extending element 5, and a second extending element 6.

[0031]The inner tube 1 comprises an upper end 11 and a lower end 12. The outer tube 2, consisting of an inner sleeve 21 made of steel and an outer sleeve 22 made of aluminum, comprises an upper end 23 and a lower end 24. Preferably the hardness of the inner sleeve 21 is higher than 200 Vickers Pyramid Number. The outer tube 2 has a diameter greater than that of the inner tube 1, and the outer tube 2 is configured to allow at least a portion of the lower end 12 of the inner tube 1 to slide into the upper end 23 of the outer tube 2.

[0032]The outer tube 2 is configured at its lower end 24 to be received by a standard seat tube receptacle of a bicycle f...

second embodiment

[0052]Referring to FIG. 14, a multi-position adjustable height seat post comprises a triggering device 4 which is a push rod connected to the actuating unit 31.

third embodiment

[0053]Referring to FIG. 15, a multi-position adjustable height seat post comprises an outer tube 2, consisting of an outer sleeve 22 and four inner pieces 21 made of steel.

[0054]To sum up the above statements, the multi-position adjustable height seat post has several obvious advantages below:

[0055]First, the internal locking mechanism improves external appearance of the inner tube 1. It hides wear damage of the interface inside on the outer tube 2 for a like new external appearance in comparison with the U.S. Pat. No. 8,079,772 patent.

[0056]Second, the smooth circular inner tube 1 provides a proper to sealing surface for wiper seal preventing dirt, water, and other contaminants from entering inside mechanism.

[0057]Third, it allows for weight reduction in virtue of the replacing of coil spring with air spring (second extending element 6).

[0058]Fourth, the wear resistance is better in virtue of the steel material of the inner sleeve 22 of outer tube 2.

[0059]Fifth, its easier to fabri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com