Cooling system and electronic apparatus using the same

a technology of electronic equipment and cooling system, applied in the field of cooling system, can solve the problems of air-based cooling apparatus already coming close to a point where its cooling performance is not enough, and cannot typically maintain its performance, so as to improve heat transfer performance, reduce heat generation, and improve heat transfer performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

embodiment 1

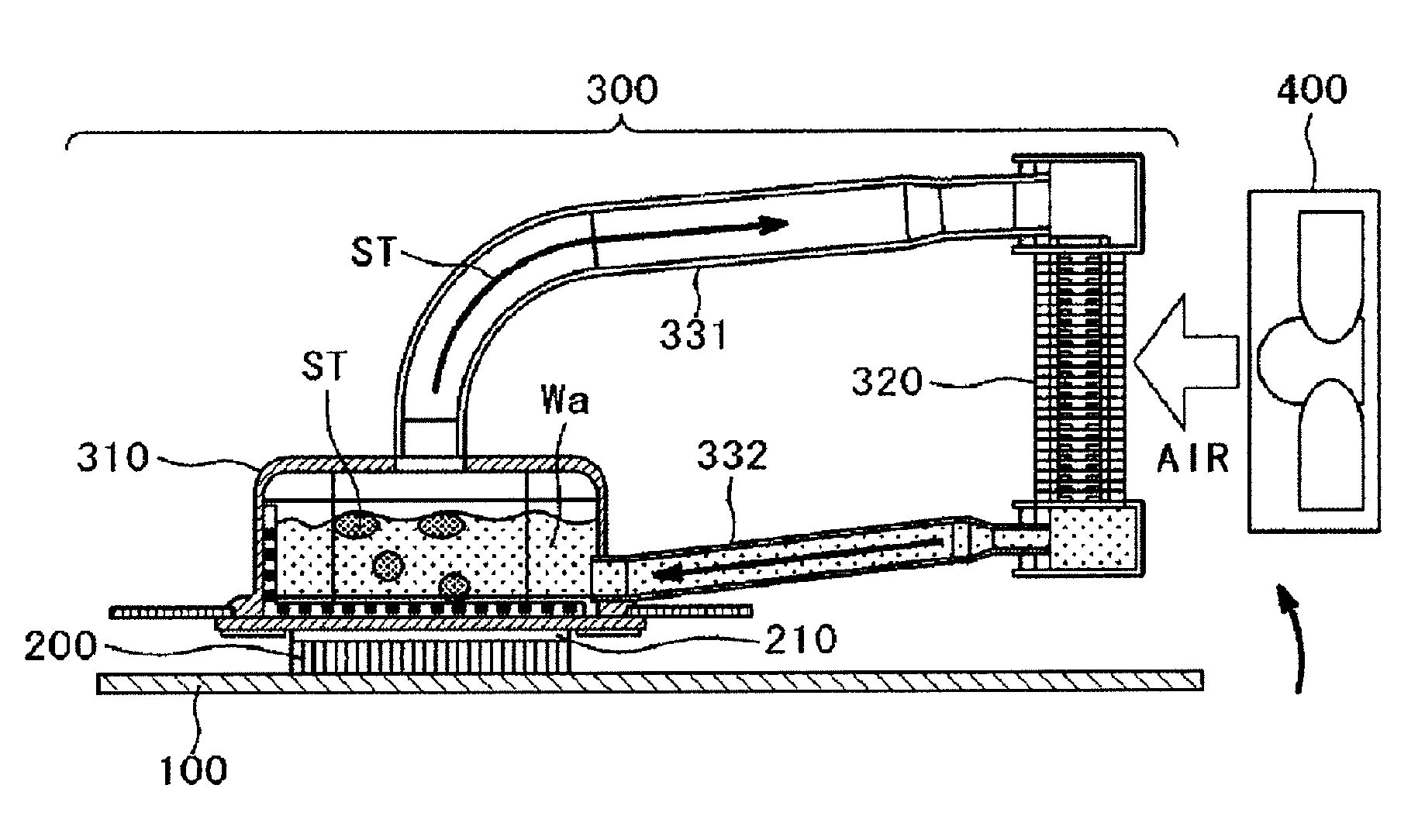

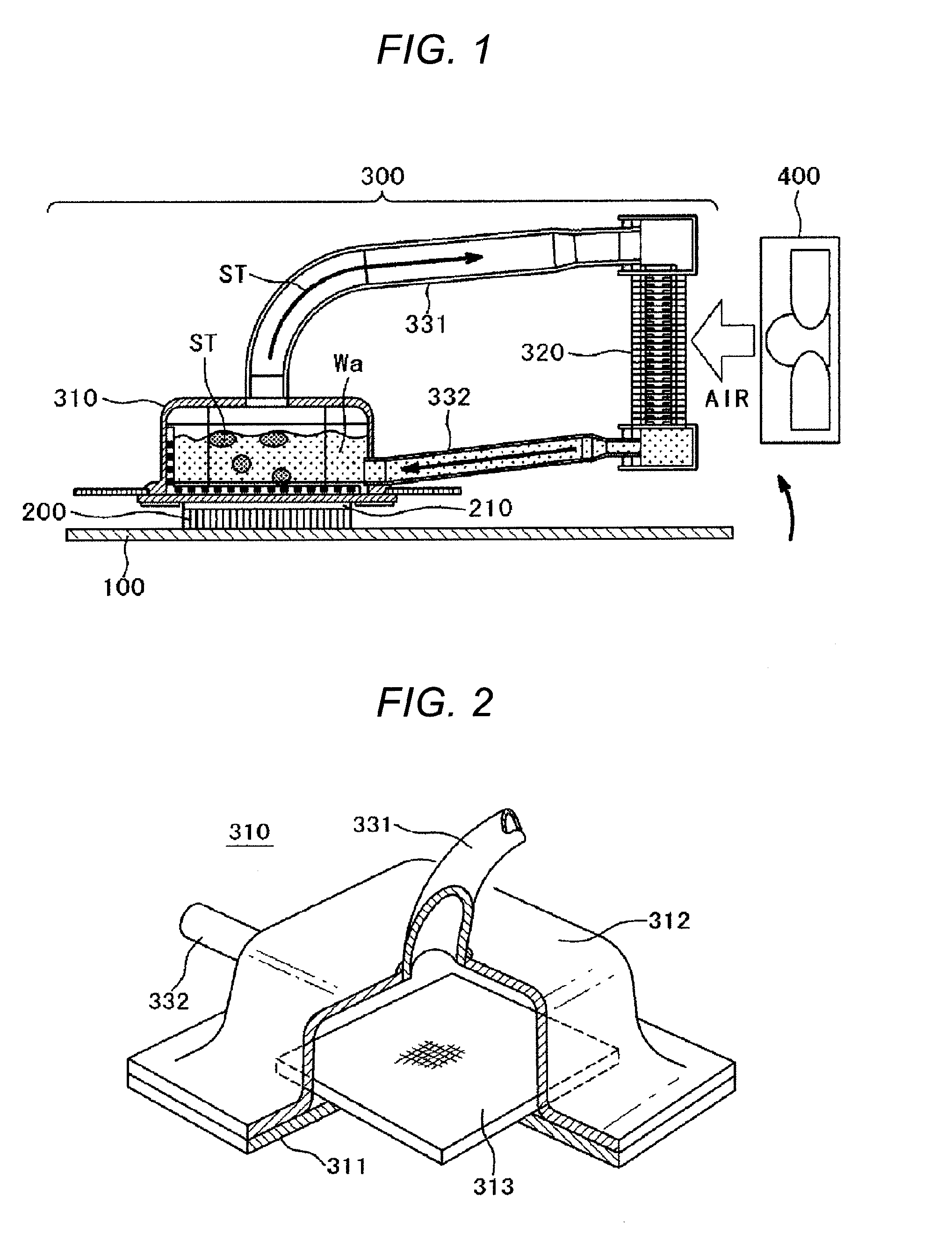

[0027]FIG. 1 shows an overall structure of a cooling system using a thermosiphon. In FIG. 1, a semiconductor device 200, such as a CPU, is mounted as a heat generating source on a surface of a circuit substrate 100. A heat receiving jacket 310, which forms part of a cooling system 300 using a thermosiphon according to the invention, is attached to the front surface of the semiconductor device 200. More specifically, what is called a heat conductive grease 210 is applied onto the front surface of the semiconductor device 200 in order to ensure a satisfactory thermal joint between the semiconductor device 200 and the heat receiving jacket 310, and the heat receiving jacket 310 is fixed with screws (not shown) or any other fixtures to the front surface of the semiconductor device 200 with the front surface of the semiconductor device 200 in contact with the bottom surface of the heat receiving jacket 310. The cooling system 300, the structure of which will be described below in detail,...

embodiment 2

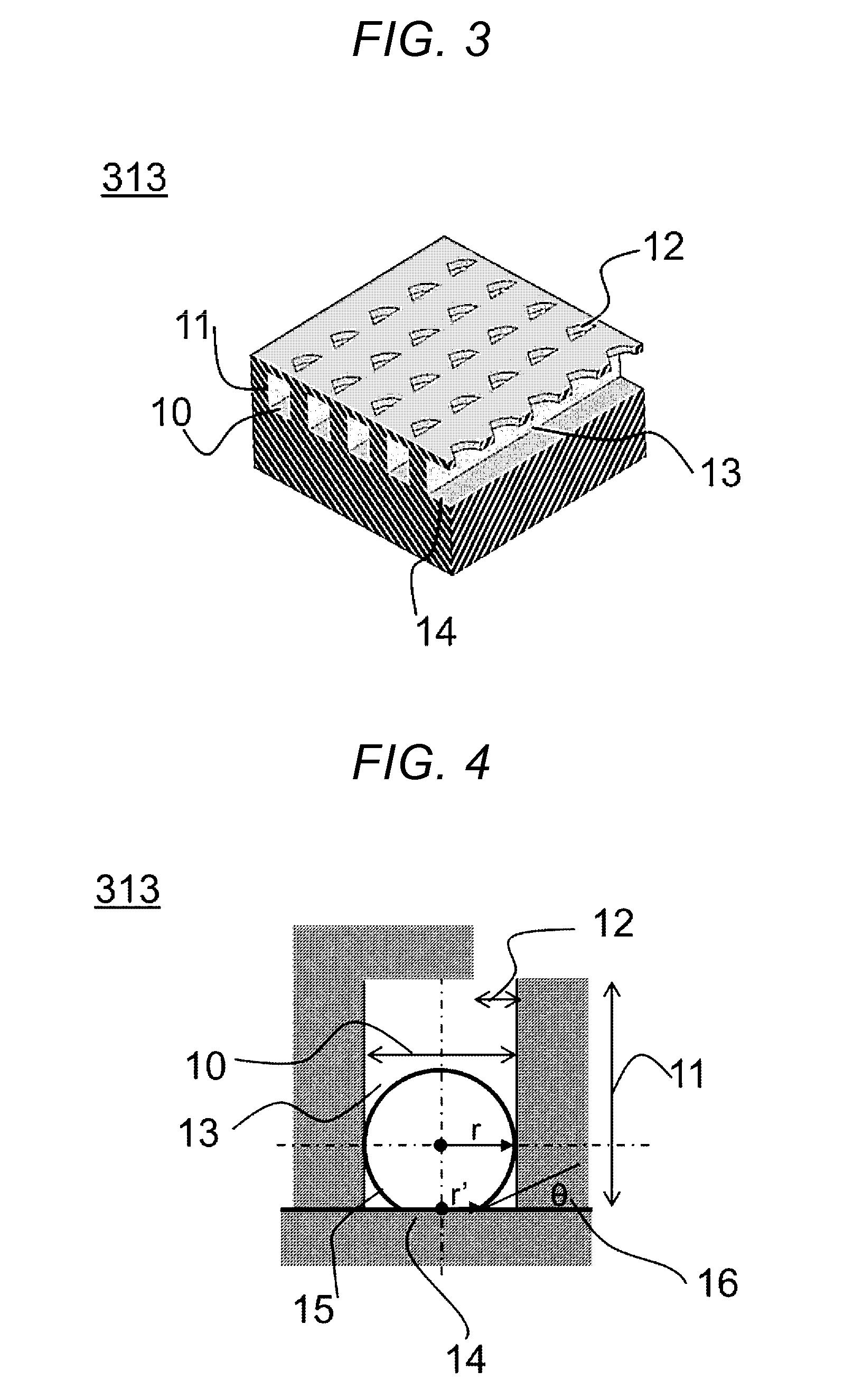

[0043]The fin height of a boiling heat transfer surface will further be described. The shape of a departing steam bubble 15 changes in accordance with the size of the inter-fin gap 10, as shown in FIGS. 5 and 6. FIG. 5 is a cross-sectional view showing a steam bubble generated when the vaporization accelerator plate, which forms the cooling system using a thermosiphon, has a narrow inter-fin gap. In this case, the steam bubble 15 is in contact with the fins and hence has an elongated shape along the space between the fins.

embodiment 3

[0044]On the other hand, FIG. 6 is a cross-sectional view showing a steam bubble generated when the vaporization accelerator plate has a wide inter-fin gap. In this case, the steam bubble 15 departs without touching the fins. In the invention, to improve the heat transfer performance by increasing the fin area, the inter-fin gap 10 is narrowed. That is, Embodiment 3 will be described with reference to the case shown in FIG. 5, in which the inter-fin gap is narrow. The buoyancy of a steam bubble can be expressed as follows in consideration of the balance between the buoyancy and the surface tension of the steam bubble by using a steam bubble volume V, the gravitational acceleration g, the steam density ρv, the liquid density ρl, the radius r′ of the steam bubble 15 to the interface between the steam bubble 15 and the heat transfer surface, the surface tension σ, the contact angle θ, and a surface roughness coefficient K.

V·g·(ρl−σv)=2·π·r′·σ·sin θ·K

where the surface roughness coeffic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com