Process and apparatus for removing hydrogen sulfide

a hydrogen sulfide and hydrogen sulfide technology, applied in the field of process and an apparatus for removing hydrogen sulfide, can solve problems such as product specifications that cannot meet the requirements of production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

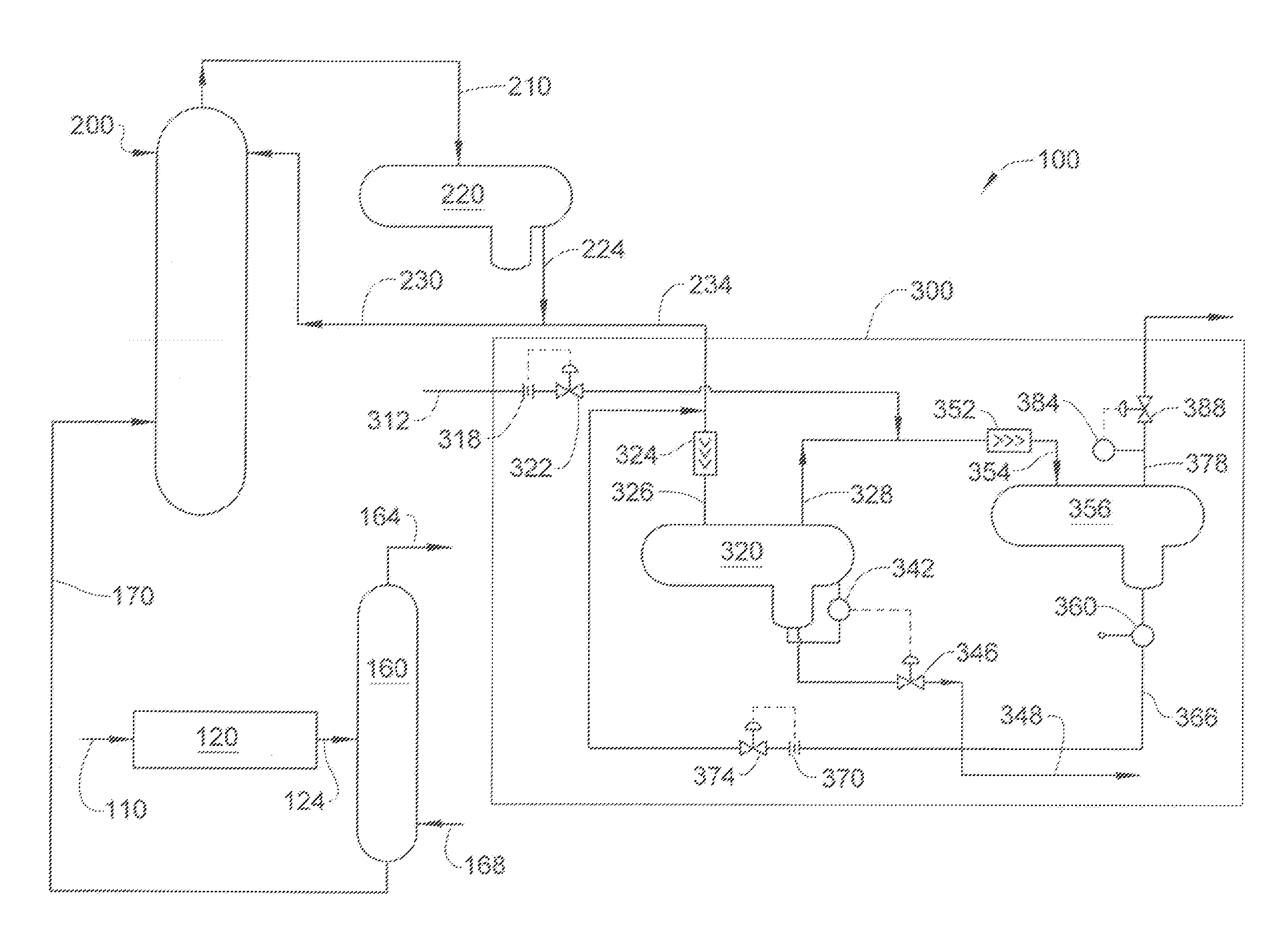

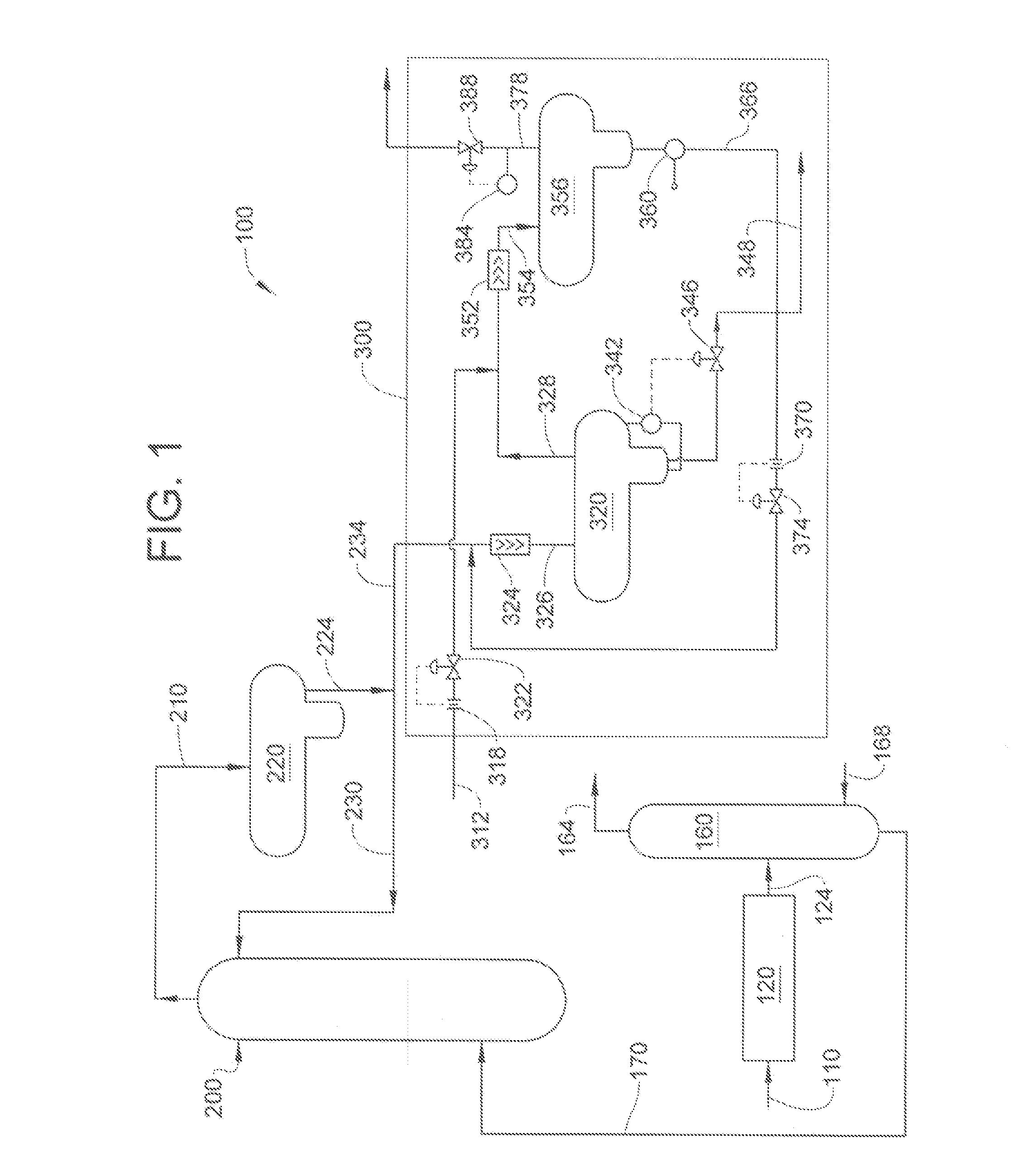

[0024]Referring to FIG. 1, an exemplary apparatus 100 can include a hydroprocessing zone 120, a primary stripper 160, a fractionation column 200, and a hydrogen sulfide removal zone 300. Generally, the hydroprocessing zone 120 can receive a feed 110 that often contains one or more hydrocarbons.

[0025]Often, the feed 110 can be any suitable heavy oil feedstock. Such a heavy oil feedstock can include one or more hydrocarbonaceous streams having components boiling above about 280° C., such as atmospheric gas oils, vacuum gas oils, deasphalted, vacuum, and atmospheric residua, coker distillates, straight run distillates, solvent-deasphalted oils, pyrolysis-derived oils, high boiling synthetic oils, cycle oils, hydrocracked feeds, and cat cracker distillates, although hydrocarbons boiling below about 280° C. may be present as well. These hydrocarbonaceous feed stocks may contain from about 0.1-about 4%, by weight, sulfur. Other suitable heavy oil feedstocks are disclosed in, e.g., U.S. Pa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

| pressure | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com