Laminating Apparatus and Method of Using the Same

a technology of laminating apparatus and lamination plate, which is applied in the direction of photomechanical apparatus, instruments, printing, etc., can solve the problems of difficult to maintain small dots on flexographic plates, difficult to print fine dots, lines and even text, and easy damage to press surfaces, etc., to achieve the effect of improving lamination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

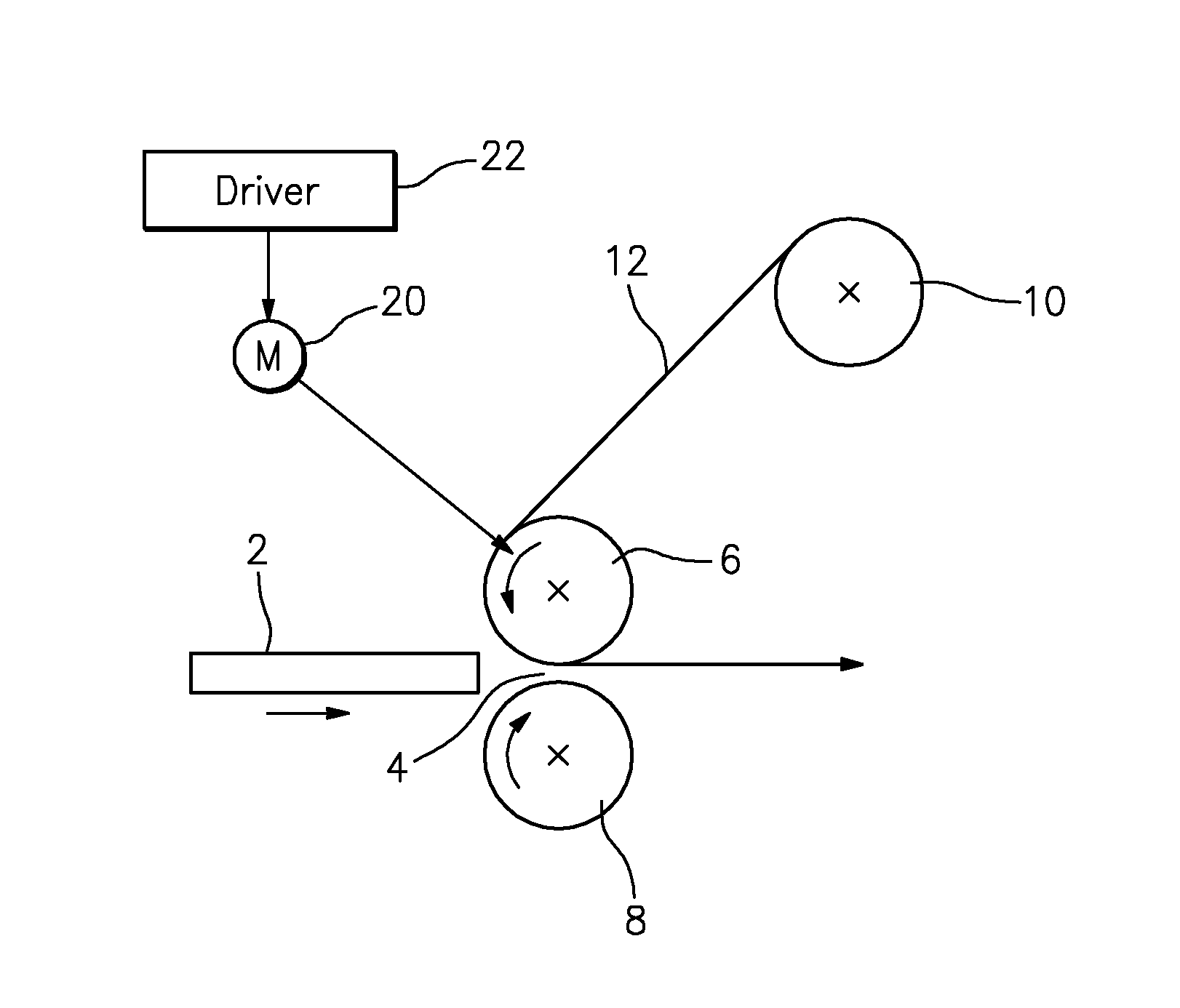

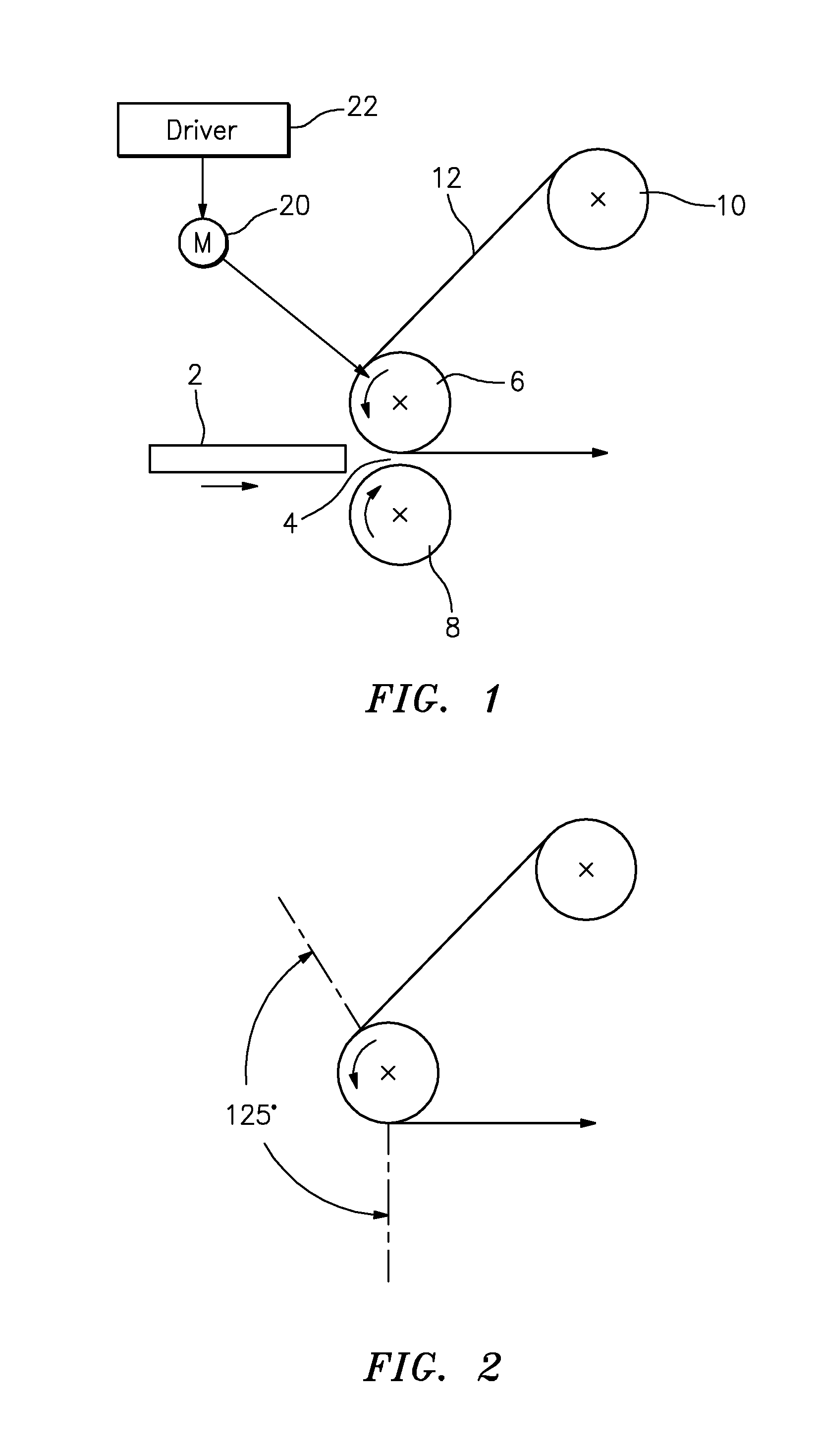

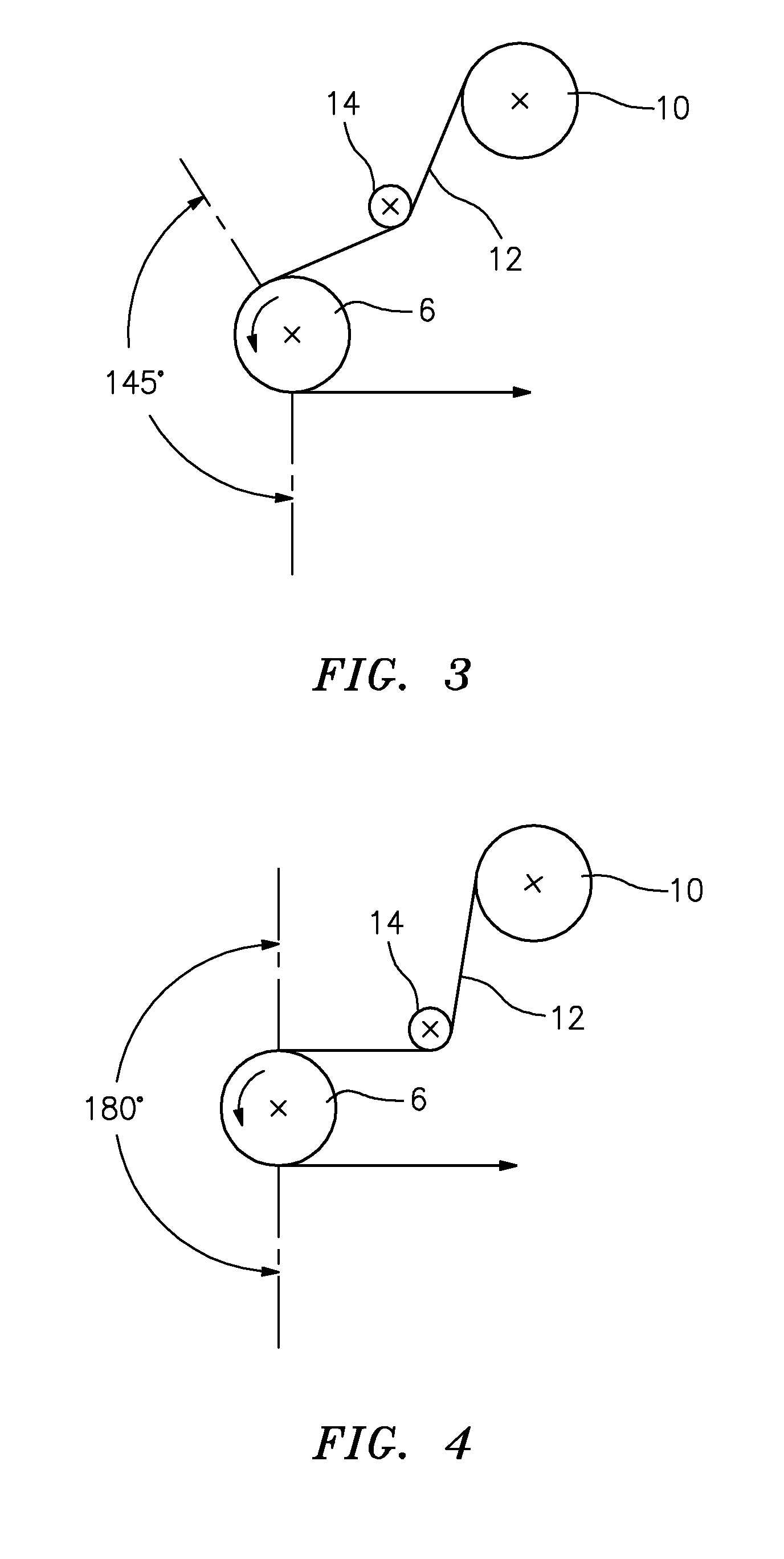

[0035]The present invention relates generally to the use of a splitter bar or other similar means to control the tension and minimize and remove wrinkles and waves in a laminating film or membrane prior to lamination to an underlying substrate. The inventors of the present invention have found that by moving the splitter bar, which changes the wrap angle between the laminating film and the heated laminating roller, a substantial improvement in the reliability of the lamination process can be realized.

[0036]Splitter bars have typically been used in laminating systems to separate release liners from pressure sensitive adhesives. However, to the inventor's knowledge, splitter bars and other similar devices have not previously been used to control tension or eliminate wrinkles during the lamination process.

[0037]The advantage of the present invention is to keep constant controlled contact of the membrane to the heated laminating roller to enable wrinkle free lamination at the nip point....

PUM

| Property | Measurement | Unit |

|---|---|---|

| optical transparency | aaaaa | aaaaa |

| optical transparency | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com