Air engine with rotatable intake-exhaust mechanism

a technology of air engine and intake-exhaust valve, which is applied in the direction of machines/engines, oscillatory slide valves, servomotors, etc., can solve the problem that the efficiency of air engine cannot be effectively enhanced, and achieve the effect of increasing the working efficiency of air engin

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

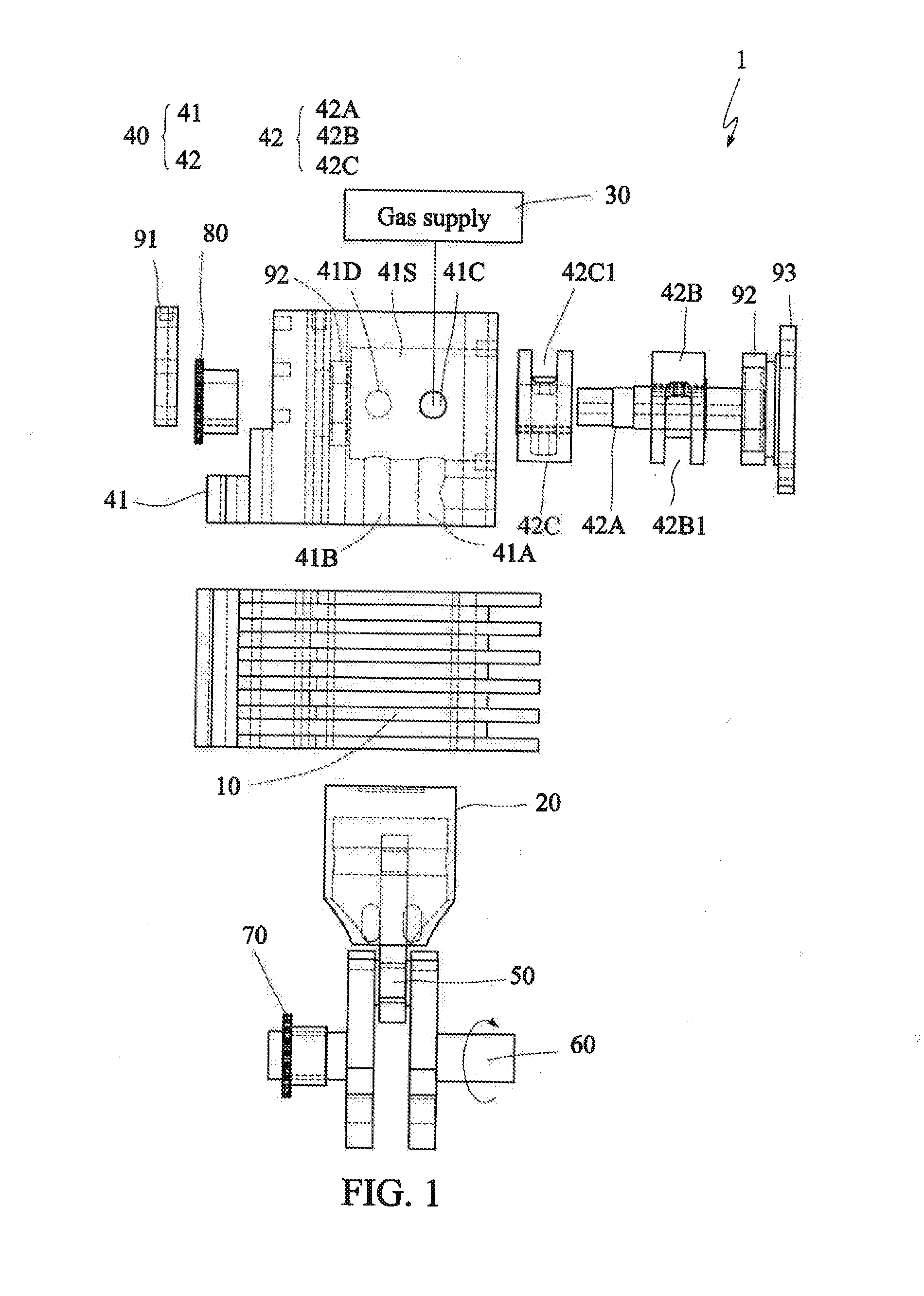

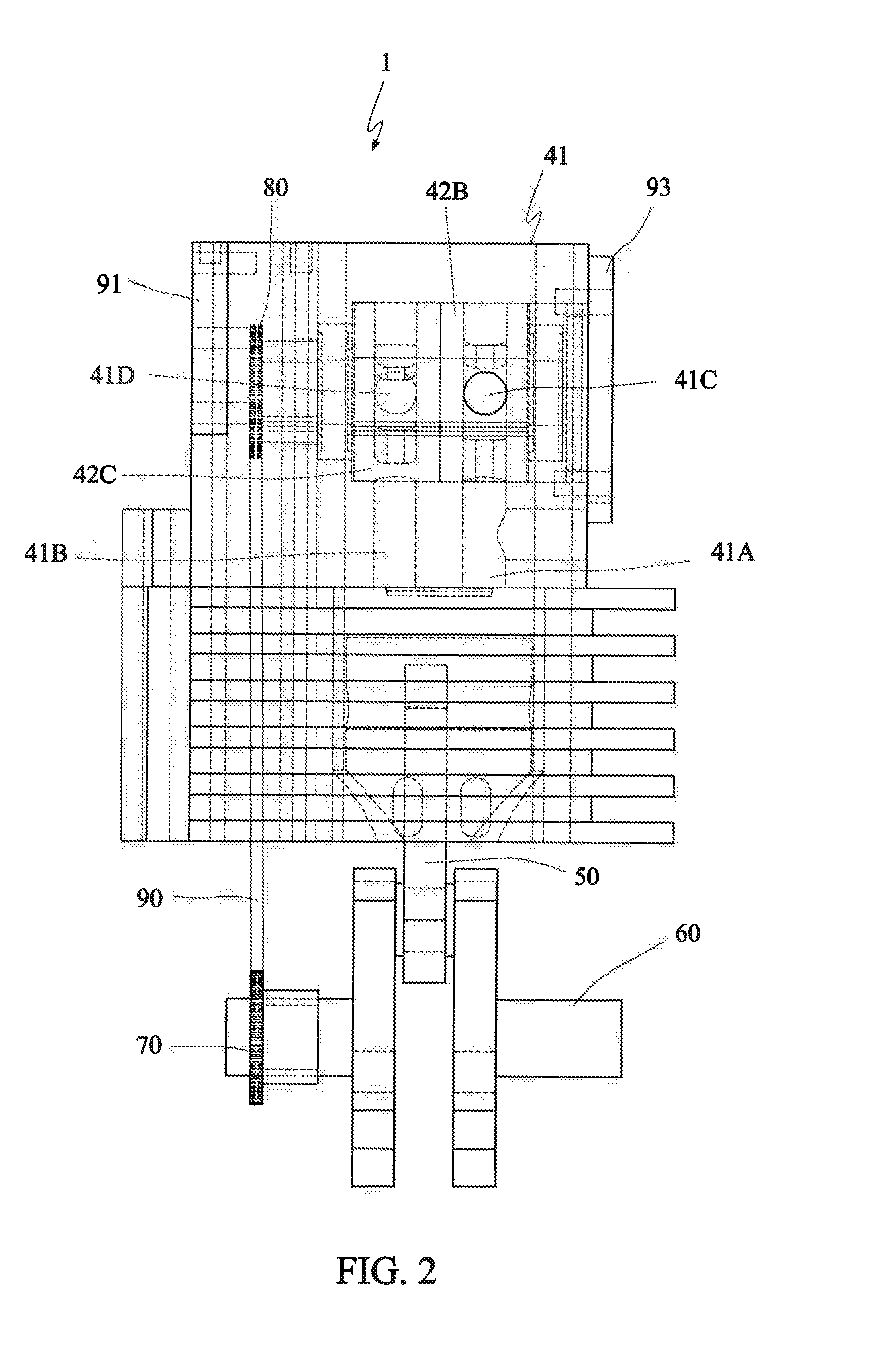

[0039]FIGS. 4C and 4D are schematic illustrations showing an intake state of the air engine at the same time instant according to the invention. In FIGS. 4C and 4D, the intake stroke is depicted, wherein the compressed gas CA enters the intake passage 42B1 of the intake member 42B from the inlet port 41C. At this time, the intake passage 42B1 concurrently communicates with the inlet port 41C and the intake channel 41A, so that the compressed gas CA can enter the cylinder 10 in the path indicated by the arrow, and then push the piston 20 and thus push the crankshaft 60 through the link 50. The crankshaft 60 rotates the crankshaft sprocket 70, and thus rotates the intake-exhaust sprocket 80 through the chain 90. Also, the intake-exhaust sprocket 80 rotates the rotating shaft 42A so that the intake member 42B and the exhaust member 42C are rotated concurrently. In FIG. 4D, the exhaust passage 42C1 contains the exhaust gas EA, generated after the compressed gas CA expands to do the work...

third embodiment

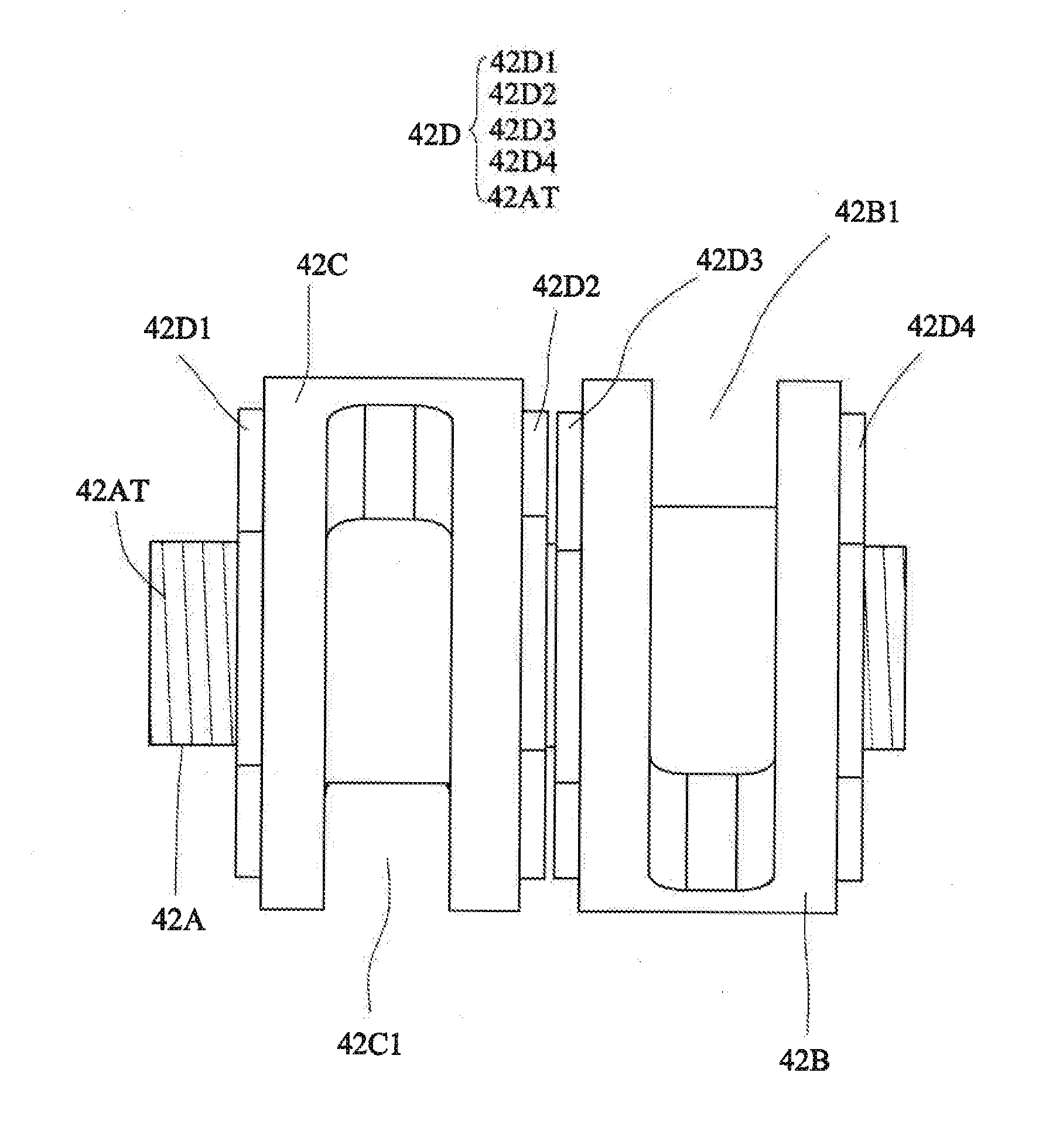

[0046]FIG. 7 is a partial cross-sectional view showing an intake-exhaust assembly according to the invention. As shown in FIG. 7, the rotating shaft 42A may also be coupled to the intake member 42B or the exhaust member 42C using a spline SP. The relative relationship between the intake timing and the exhaust timing is adjusted by adjusting the spline. That is, the rotating shaft 42A may be rotated relatively to the intake member 42B or the exhaust member 42C before the intake member 42B or the exhaust member 42C are mounted on the rotating shaft 42A through the spline SR

[0047]FIGS. 8A to 8C show three examples of intake-exhaust paths according to the invention. In the first embodiment, the included angle A1 between the inlet port 41C and the intake channel 41A is equal to 90 degrees, and the included angle A2 between the outlet port 41D and the exhaust channel 41B is also equal to 90 degrees, as shown in FIG. 8A. In another example, however, the included angles A1 and A2 are equal ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com